- Home ›

- IGBT Heat Sink

IGBT Heat Sink Manufacturing

Specialized thermal management solutions engineered for Insulated Gate Bipolar Transistors. Our precision CNC-machined heat sinks ensure optimal cooling performance for high-power switching applications in industrial drives, renewable energy systems, and automotive power electronics.

Get Custom QuoteWhat is an IGBT Heat Sink?

An IGBT heat sink is a critical thermal management component specifically designed to dissipate heat generated by Insulated Gate Bipolar Transistors during high-power switching operations. IGBTs are widely used in power conversion applications where they handle hundreds to thousands of watts, making efficient heat dissipation essential for reliable operation and extended component lifespan.

These specialized heat sinks must handle rapid thermal cycling, high power densities, and demanding environmental conditions. Our IGBT heat sinks feature optimized fin geometries, superior thermal conductivity materials, and precision mounting interfaces that ensure consistent thermal performance across variable load conditions.

IGBT Heat Sink Solutions

Extruded Aluminum Solutions

Cost-effective extruded aluminum heat sinks with optimized fin density for soft starters and industrial inverters.

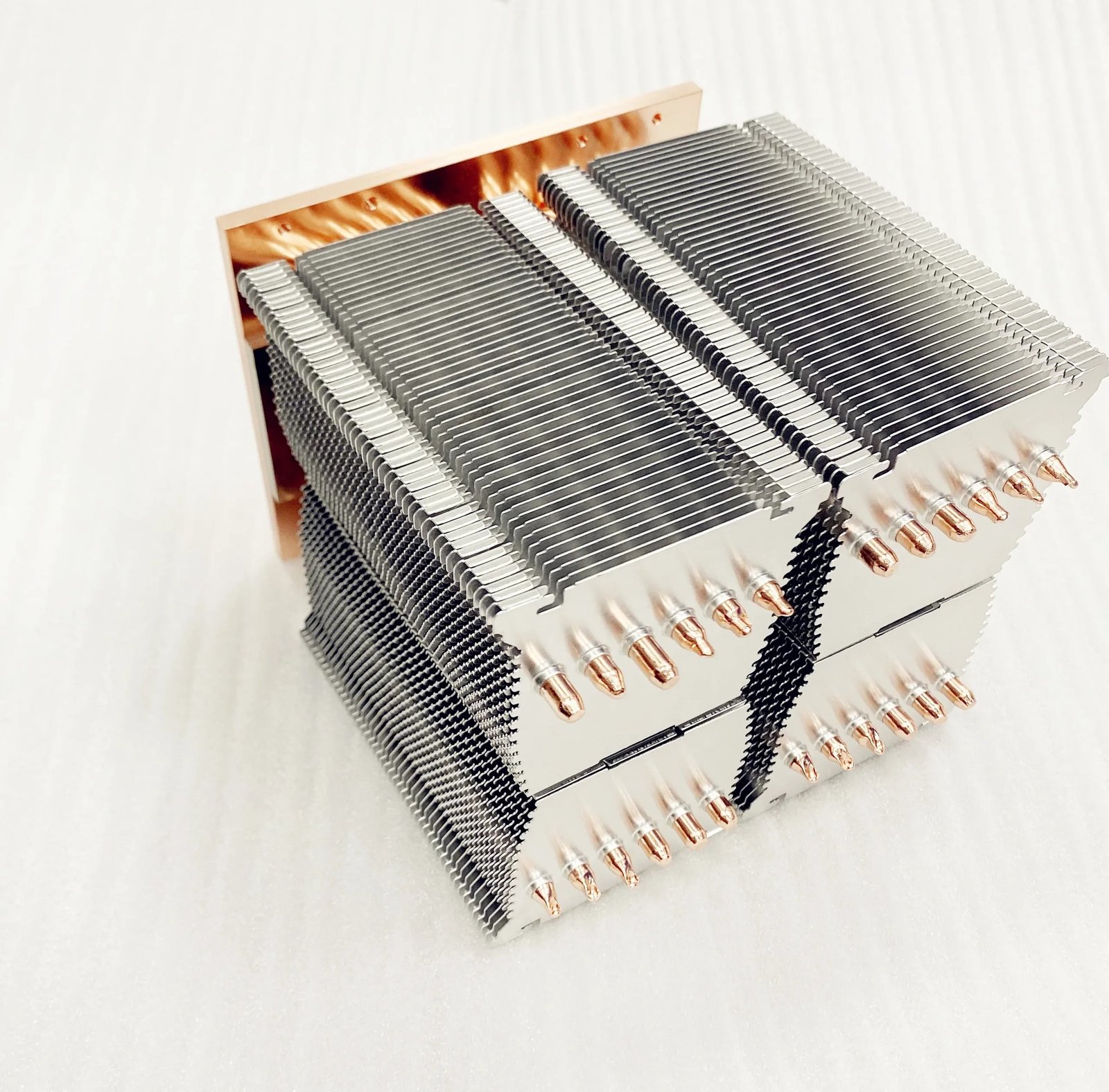

High Power Configurations

Custom high-power IGBT heat sinks designed for demanding applications with exceptional thermal performance.

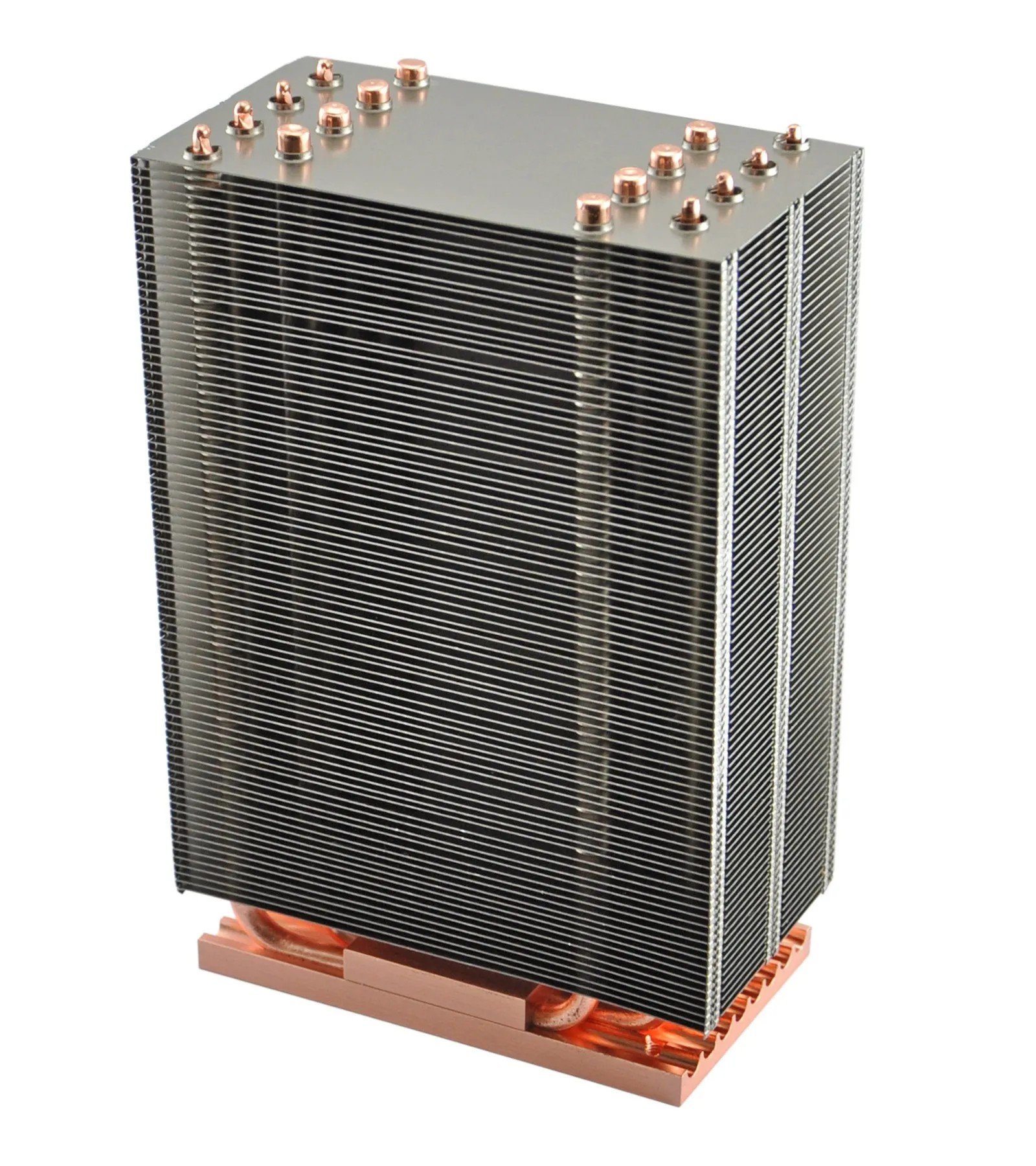

Deep Fin Designs

Deep fin cooling heatsinks for IGBT diode inverters maximizing surface area for enhanced heat dissipation.

Liquid Cooling Systems

Water-cooled IGBT module heat sinks with integrated heat pipe technology for ultra-high power applications.

UPS & Inverter Solutions

High-fin heat sink extrusions specifically engineered for IGBT modules in UPS and converter applications.

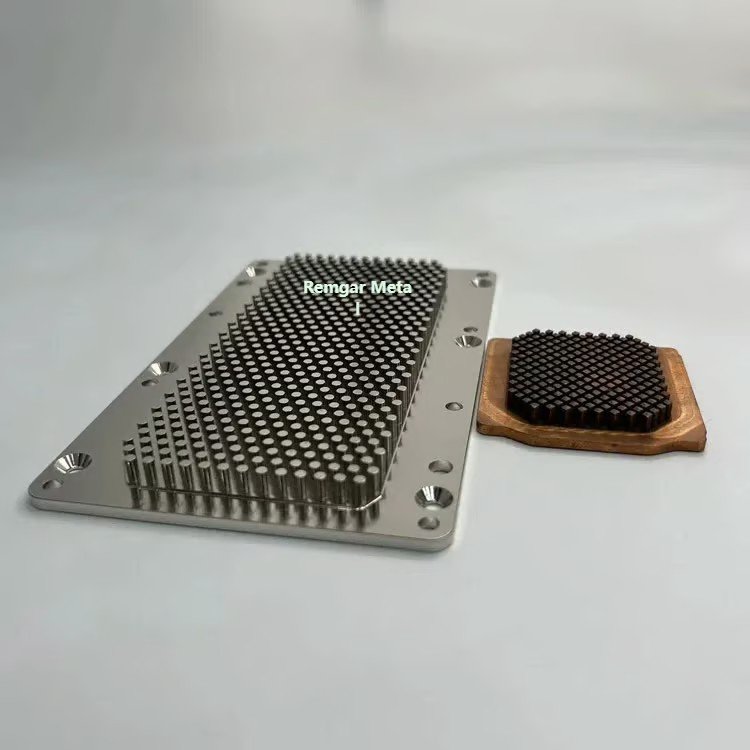

Automotive Applications

BYD customized IGBT inverter heatsinks with pin fin and cold forging technology for electric vehicles.

Skived Fin Technology

Copper skived fin heatsinks for automotive IGBT modules delivering maximum thermal conductivity.

Custom Designs

Fully customized IGBT heat sinks tailored to your specific power electronics requirements and constraints.

Key Performance Features

Superior Thermal Conductivity

Aluminum 6063-T5 and copper materials providing excellent heat transfer from IGBT modules to ambient environment.

Optimized Fin Geometry

Precisely engineered fin spacing and height balancing thermal performance with airflow resistance.

Precision Mounting Interfaces

CNC-machined flat surfaces ensuring optimal thermal contact with IGBT modules and minimal thermal resistance.

Surface Treatment Options

Anodizing, nickel plating, and powder coating for enhanced durability and electrical insulation.

Primary Applications

IGBT heat sinks are essential components across diverse high-power electronics applications

Industrial Drives

Variable frequency drives and motor control systems

Solar Inverters

Photovoltaic power conversion systems

EV Powertrains

Electric vehicle traction inverters

Rail Traction

Locomotive and transit system power electronics

UPS Systems

Uninterruptible power supply inverters

Wind Turbines

Wind power generation converters

Charging Stations

EV fast charging infrastructure

Welding Equipment

Industrial welding power supplies

Design Considerations

Thermal Resistance Calculation

Precise thermal resistance modeling ensures junction temperatures remain within safe operating limits across all load conditions and ambient temperatures.

Mounting Pressure Distribution

Uniform mounting pressure distribution across IGBT modules minimizes thermal interface resistance and ensures consistent thermal performance.

Cooling Method Selection

Choose between natural convection, forced air, or liquid cooling based on power dissipation requirements and space constraints.

Frequently Asked Questions

Why do IGBT modules require specialized heat sinks?

What materials are best for IGBT heat sinks?

How do you select the right IGBT heat sink size?

What surface finishes are available for IGBT heat sinks?

Can you customize IGBT heat sinks for specific modules?

What testing do you perform on IGBT heat sinks?

Ready to Enhance Your IGBT Thermal Management?

Partner with Rapidaccu for precision-engineered IGBT heat sinks that deliver reliable performance in the most demanding power electronics applications.

Request Engineering ConsultationRequest Your Custom Quote

Contact Rapidaccu

Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

15 Years in Precision CNC Manufacturing

Why Choose Rapidaccu?

- Advanced 5-axis CNC machining

- 15 years thermal solution expertise

- Custom design capabilities

- Comprehensive quality testing

- Global shipping services