Custom Parts Manufacturer for Precision Metal & Plastic Components

Rapidaccu supports engineers and buyers with CNC machining, sheet metal, injection molding, 3D printing, stamping, and surface finishing—built around DFM clarity, traceable documentation, and export-ready delivery.

Precision

Tight tolerance builds

QA-first

Inspection-driven flow

DFM

Cost & risk reduction

Export

Global delivery ready

Instant Project Checklist

Best for RFQCAD / Drawing

STEP/IGES + PDF tolerances & notes

Material & Certification

Specify grade and 3.1 certificate if required

Finish & Cosmetic Standard

Anodize, plating, coating, blasting, passivation

Inspection Scope

Dim report, CMM, NDT (UT/MT/PT) if applicable

Procurement-friendly

Clear cost drivers, traceability-focused documentation

Manufacturing You Can Audit and Trust

Buyers evaluate suppliers on risk, repeatability, and documentation—not only on price. Our workflow reduces hidden costs from rework, unclear specs, and inconsistent batches.

Clear, engineer-readable RFQs

We quote by manufacturing reality: datum logic, tolerance stack, tool access, and finishing constraints—so you can approve with confidence.

Inspection-driven production

Defined checkpoints, dimensional reports, and batch traceability help reduce surprises during incoming inspection and assembly.

DFM that actually saves money

Typical savings come from radius strategy, feature simplification, tool path efficiency, and finish selection—without compromising function.

Prototype-to-production continuity

Keep the same manufacturing intent from first article to batches, so you don’t relearn the process every time you reorder.

Core Parts Manufacturing Capabilities

Choose a process, get DFM clarity, and move from quote to compliant delivery with fewer iterations.

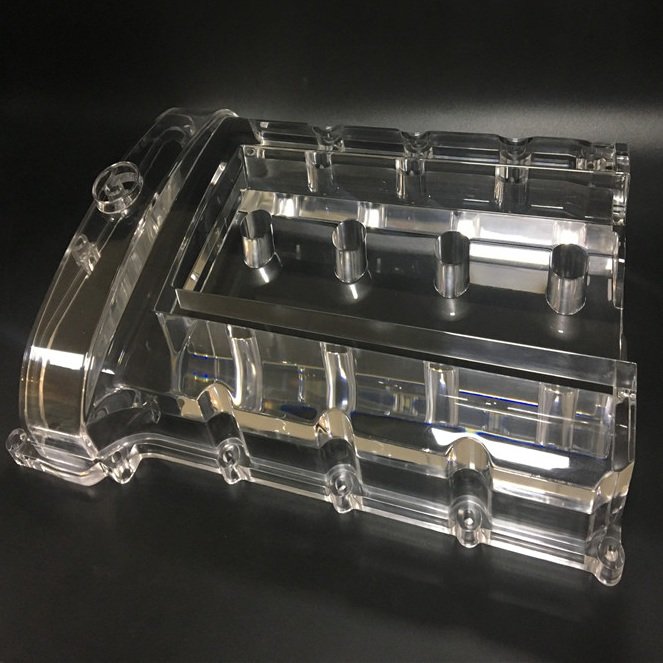

CNC Machining

3/4/5-axis | tight tolerances | metals & plastics

Fast prototypes, stable batches.

View

Sheet Metal Fabrication

Cut | bend | weld | assemblies

Enclosures, brackets, frames.

View

Injection Molding

Tooling | pilot runs | production

Repeatable parts at scale.

View

3D Printing

Rapid prototypes | functional validation

Fast iteration cycles.

View

Stamping

Progressive dies | throughput builds

Cost-efficient production.

View

Surface Finishing

Anodize | plating | coating | passivation

Finish matches function.

ViewMore processes are available

These capabilities are ready, but we’re not linking them yet. Use the RFQ form to route your project to the right team.

Route My Project

Forging

Strength-critical components

Die Casting

Volume metal parts

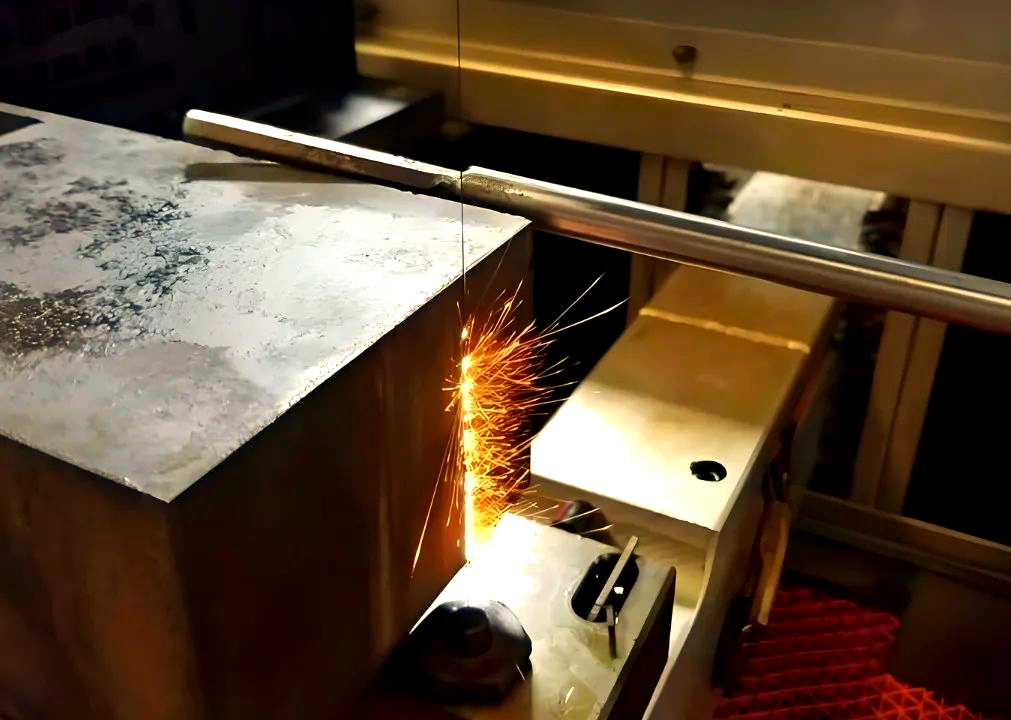

Wire Cutting EDM

Hard materials & sharp corners

Aluminum Extrusion

Profiles & heat sinks

Engineering Capability & Manufacturing Limits

Transparent capability ranges reduce engineering risk and speed up project approval. Below are our standard manufacturing limits. Custom requirements can be evaluated during DFM review.

| Capability | Range / Specification | Notes |

|---|---|---|

| Max Part Size (CNC) | 1200 mm × 800 mm × 600 mm | Larger parts upon evaluation |

| Min Tolerance | ±0.005 mm | Depends on material & geometry |

| Surface Finish | Ra 0.4 – 3.2 µm | Grinding / polishing available |

| Batch Volume | 1 – 100,000+ pcs | Prototype to mass production |

| Materials Supported | 50+ Metal & Plastic Grades | Including high-temp alloys |

| Material Certification | EN 10204 3.1 Available | Heat number traceability |

| Inspection Equipment | CMM / Height Gauge / Surface Tester | Full dimensional report provided |

| NDT Capability | UT / MT / PT (On Request) | For aerospace & critical parts |

| Quality System | ISO 9001 Certified | Process-controlled production |

Have special tolerance or certification requirements?

Upload your drawing and specify material grade, NDT requirement, or dimensional report format. Our engineering team will review and confirm feasibility within 24 hours.

Custom Parts Materials Expertise

Material selection decides cost, performance, and inspection risk. Explore plastics and metals with a manufacturing-first lens—machinability, stability, surface finish, and traceable documentation.

Traceable documentation

Request 3.1 material certificates, heat numbers, and inspection reports when required.

Heat treatment aware

Design choices consider distortion risk, post-processing, and real-world tolerance stability.

Corrosion & wear choices

Match alloys and finishes to environment, friction, and lifecycle needs.

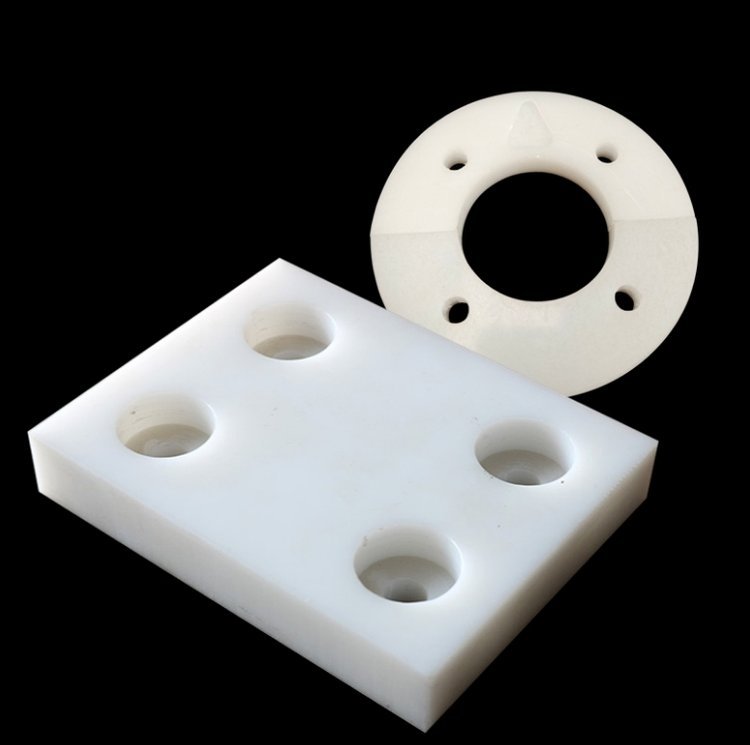

Plastics

Machining-grade plastics for fixtures, housings, insulators, and wear parts.

Metals

Machining-ready metals for structural strength, conductivity, corrosion resistance, and heat performance.

Aluminum

Lightweight, corrosion resistance

Housings & fixtures

View

Brass

Machinability, clean finish

Fittings & precision parts

View

Bronze

Wear resistance, low friction

Bushings & wear parts

View

Copper

Thermal & electrical conduction

Busbars & thermal parts

View

Stainless Steel

Corrosion resistance, strength

Industrial & hygienic use

View

Titanium

High strength-to-weight

Aerospace & medical

View

Tool Steel

Hardness, wear resistance

Jigs, dies & tooling

View

Cast Iron

Damping, cost-effective

Bases & structures

ViewTip

If your project involves high temperature alloys (e.g., Inconel), add it in the RFQ and we’ll route it to the right team.

Quality & Documentation, made simple

A premium supplier is judged by what happens after the PO: inspections, traceability, and prevention. We align with procurement expectations so receiving inspection and audits are smoother.

Dimensional & Visual Inspection Report

Clear, part-numbered, batch-linked reporting.

Material traceability & certificates

3.1 certificates, heat numbers, and traceability records as requested.

NDT options (UT / MT / PT)

Specify scope during RFQ; we align it to the drawing and risk points.

CoC / Declaration of Conformity

Issued per production batch for full traceability.

What buyers often miss

Cost drivers are not only material

Tolerances, finishing, inspection scope, and feature design often dominate cost and lead time. We make these tradeoffs transparent during DFM.

Tolerance

Stack & inspection

Finish

Function vs cosmetic

Geometry

Tool access

Batch

Traceability

Example DFM outcome

Reduce cost without reducing performance

We often help customers simplify features that drive setup time and tool changes.

Before

Unnecessary internal features increase cycle time and tooling complexity.

After

Refined geometry improves manufacturability and stabilizes repeat orders.

Request a Quote

Send your drawings and requirements. We’ll align process selection, inspection scope, and finishing to your functional needs—so your RFQ is approval-ready.

What to include

STEP/IGES + PDF drawing, material/finish, quantity, certification needs.

Delivery

Export-grade packaging options for international shipments.

Share your requirements

We respond with a manufacturing-aligned quotation and a clear scope of documents and inspections.

Fast routing

We route your RFQ to the correct process owner.

DFM clarity

We highlight risk points early—before production.

Doc-ready

Inspection & certificates aligned to batch traceability.

FAQ

Fast answers for engineers and procurement teams.