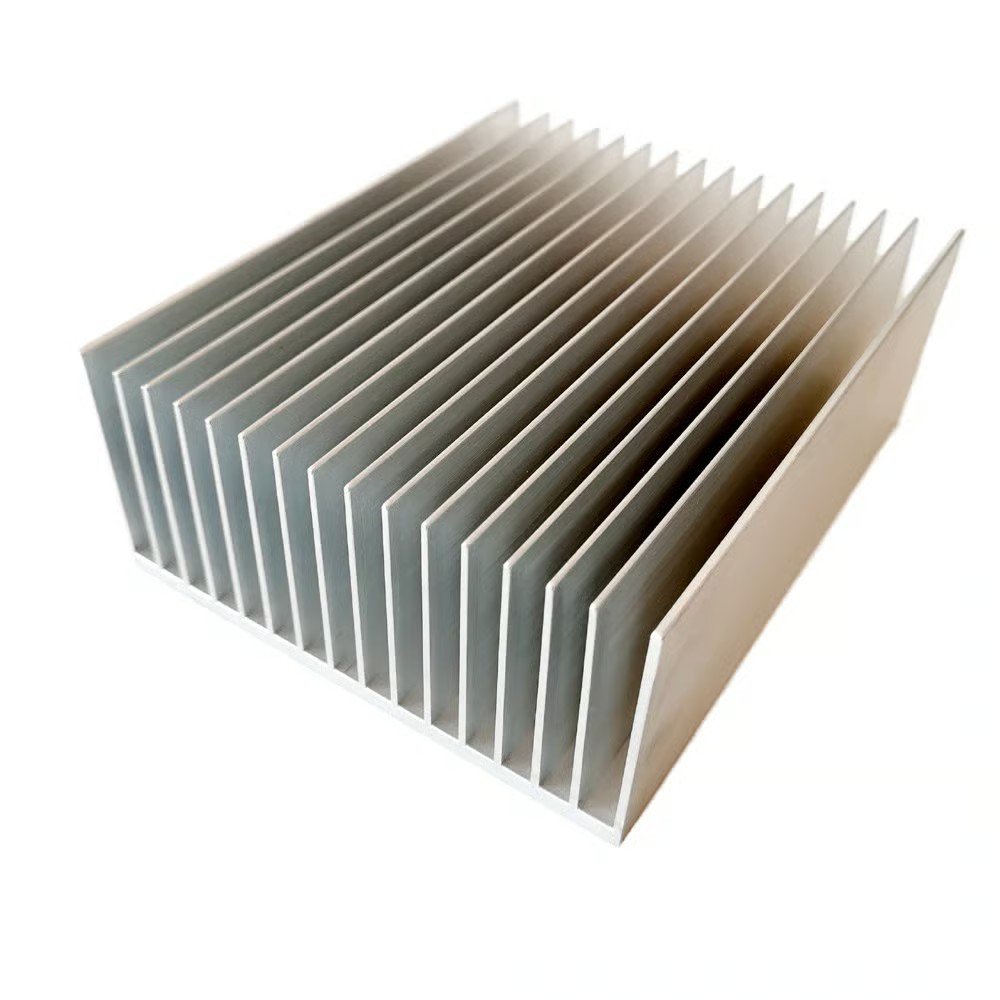

Extruded Heat Sink

Cost-effective aluminum extrusion solutions for versatile thermal management

Get Custom QuoteUnderstanding Extruded Heat Sinks

Extruded heat sinks are manufactured through an aluminum extrusion process where heated aluminum billets are forced through a die to create specific cross-sectional profiles. This process enables consistent, repeatable production of heat sink designs with excellent dimensional accuracy.

The extrusion method offers outstanding cost-effectiveness for medium to high-volume production runs, making it the preferred choice for many thermal management applications across industries.

Extruded aluminum heat sinks combine lightweight construction with good thermal conductivity, providing reliable cooling performance for power electronics, LED systems, and industrial equipment.

Key Benefits

Why extruded heat sinks are the preferred choice for efficient thermal management

Cost Efficiency

Extrusion process reduces tooling costs and enables economical production for medium to high volumes.

Design Flexibility

Custom die profiles allow unlimited fin configurations and geometries to optimize thermal performance.

Dimensional Consistency

Precise extrusion process ensures uniform cross-sections and tight tolerances across production runs.

Lightweight Structure

Aluminum construction provides excellent strength-to-weight ratio, ideal for weight-sensitive applications.

Rapid Production

Continuous extrusion process enables high output rates for meeting demanding delivery schedules.

Surface Finishing

Compatible with various treatments including anodizing, powder coating, and chemical finishing.

Product Showcase

Technical Specifications

Aluminum Alloys

6063-T5, 6061-T6 for optimal thermal conductivity

Extrusion Length

Standard lengths up to 6 meters, cut to size

Fin Height

10mm to 120mm depending on profile design

Base Thickness

3mm to 15mm for structural integrity

Surface Treatments

Natural, anodized, powder coated, chemical film

Tolerance Standards

±0.1mm to ±0.3mm based on profile complexity

Industries We Serve

Delivering reliable thermal solutions across diverse sectors

Power Conversion

Inverters, converters, power supplies

LED Systems

Street lights, industrial lighting

Telecommunications

Base stations, signal amplifiers

Automotive

EV chargers, battery management

Renewable Energy

Solar inverters, wind controllers

Industrial Control

Motor drives, automation systems

Computing

Workstations, servers, storage

Medical Devices

Diagnostic equipment, lasers

Advanced Manufacturing Capabilities

State-of-the-art facilities equipped to handle complex extrusion requirements

Frequently Asked Questions

What is the difference between extruded and skived heat sinks?

Can extruded heat sinks be customized to specific dimensions?

What aluminum alloys do you use for extruded heat sinks?

What surface finishes are available for extruded heat sinks?

What is the typical delivery time for custom extruded heat sinks?

Do you provide thermal performance testing for extruded heat sinks?

Request Your Custom Quote

Contact Rapidaccu

Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comExperience

15 Years of CNC Manufacturing Excellence

Why Partner With Us?

- Extensive extrusion die library

- Advanced CNC machining capabilities

- Comprehensive surface treatment options

- Rigorous quality control processes

- Global shipping expertise

- Technical support and consultation