Fixtures & Jigs Design and Manufacturing

Built for Production Stability, Not Just Holding Parts

Rapidaccu is a specialized custom fixtures & jigs manufacturer. We design tooling that controls repeatability, deformation, and takt time—ensuring stable yield from prototype to volume production.

What We Actually Solve

Tooling That Controls the Process (Not Just the Part)

Do you struggle with unreliable part positioning, slow assembly, or quality issues that “come and go” from one shift to the next? In most cases, the problem doesn’t start with machining or assembly—it starts with how the part is located, restrained, and released.

Rapidaccu designs and manufactures process-control fixtures and jigs that turn unstable steps into repeatable outcomes. With an engineering-led team and hands-on experience—especially in automotive production tooling, semiconductor fixtures, and optical/photonics alignment tooling—we help you stabilize your line and reduce rework.

Our fixtures are built to:

-

✓

Lock geometry before variation begins

-

✓

Control deformation caused by force, heat, and repetition

-

✓

Shorten cycle time without sacrificing accuracy

-

✓

Make inspection results repeatable and defensible

If your quality depends on “who’s on shift,” your process isn’t controlled yet. We build the tooling that makes it controlled.

Our Fixture & Jig Solutions

Machining Fixtures

Repeatable locating and deformation control for CNC milling, turning, and 5-axis systems.

Explore Machining Tooling

Welding Fixtures

Heat-aware tooling that controls distortion and sequence for robotic and manual welding lines.

Explore Welding Jigs

Assembly Jigs

Error-proofed (Poka-Yoke) stations that turn assembly into a controlled, predictable process.

Explore Assembly Stations

Metrology Fixtures

CMM, gauge, and vision fixtures designed for repeatable posture and cross-site measurement correlation.

Explore Metrology FixturesSemiconductor Tooling

IC test fixtures and encapsulation jigs built for ESD control, cleanliness, and stable yield.

Explore Semicon Tooling

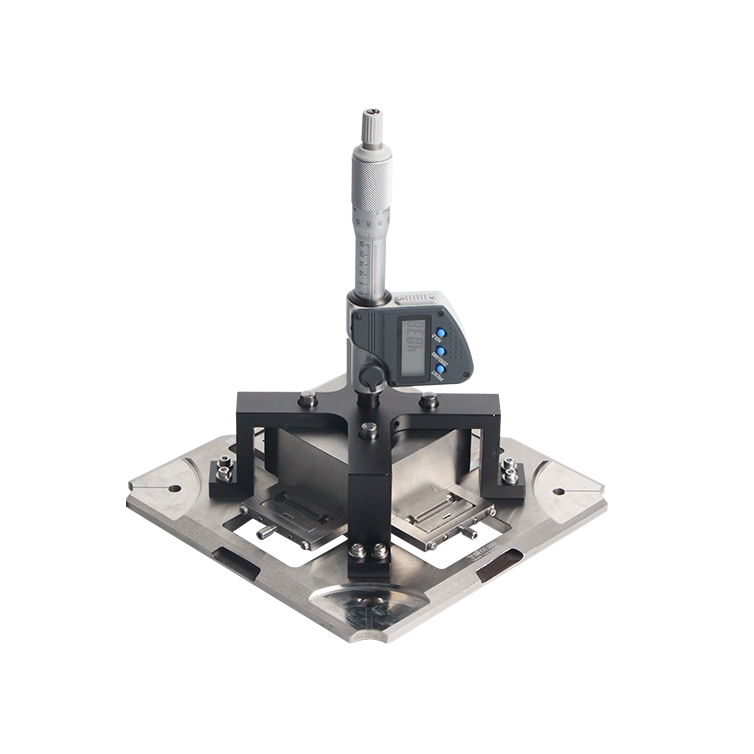

Optical & Photonics

Alignment and metrology fixtures engineered for optical stability and delicate surface protection.

Explore Optical JigsIndustries We Serve

- Automotive & EV Manufacturing

- Semiconductor & Electronics

- Optical, Photonics & Laser

- Heavy Industrial Equipment

- Aerospace & Precision Mechanical

How We Build Production-Ready Fixtures

Process Review

Analyze GD&T, failure modes, and critical steps.

Locating Strategy

Determine datum references and restraint plan.

Concept Review

Propose a design focused on risk control.

Precision Build

Machining and try-out validation for ramp-up.

Custom Tooling FAQ

How does Rapidaccu ensure measurement correlation?

Can you handle engineering changes (ECO) after the build?

What is your typical lead time for production fixtures?

Stabilize Your Process Now

Tell us where things go wrong: distortion, alignment, or inspection disputes. We’ll respond with a fixture concept and risk review—not just a price.

Email Our Engineers

info@rapidaccu.comRequest Production Assessment

Confidential Technical Review Within 24 Hours