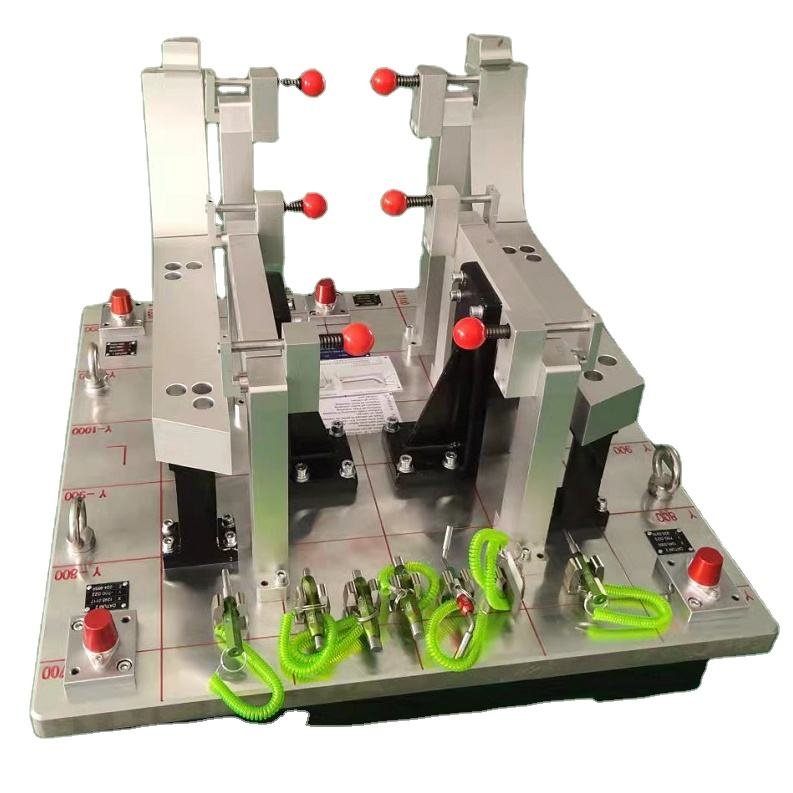

Automotive Fixtures & Jigs Manufacturer

Production-critical tooling for machining, welding, assembly, and inspection—built for repeatability, cycle time, and stable PPAP results.

- High repeatability for volume production & mixed-model lines

- Fast changeover with modular / quick-change concepts

- GD&T-driven locating strategy to control variation

Built for Automotive Manufacturing Reality

Multi-shift Stability

Robust designs meant for 24/7 high-volume environments.

Poka-Yoke Options

Error-proofing features built directly into the fixture hardware.

Maintainability

Strategic design for fast spare parts replacement and line uptime.

Audit Ready

Full documentation packages ready for any OEM/Supplier audit.

Preventing Production Failure

We don’t just build jigs; we solve the engineering problems that lead to downtime and scrap.

Analyze Your ProjectVariation Creep

→ Datums-first locating, rigid support, controlled clamping force.

Slow Changeovers

→ Modular nests, quick-change plates, standardized interfaces.

Weld Distortion

→ Controlled restraint points, sequence-aware fixture design.

Inspection Disputes

→ Checking fixture + measurement plan aligned to GD&T.

Downtime from Wear

→ Hardened wear surfaces, replaceable inserts, spares kit included with every build.

Automotive Tooling We Build

Machining Fixtures

- • CNC milling/turning for brackets & housings

- • 3-axis & 5-axis tombstone fixtures

- • Thin-wall support for lightweight components

Welding & BIW Tooling

- • Robotic MIG/TIG/Spot welding fixtures

- • BIW locating clamps & high-precision pins

- • Battery tray & enclosure welding systems

Inspection Checking

- • Customized by vehicle model requirements

- • One-to-one design for each critical part

- • CMM validation and master gauge builds

Our Automotive Tooling Process

Input & Strategy

GD&T review, datum scheme verification, and clamping plan.

Concept Design

Accessibility, chip evacuation, ergonomics, and poka-yoke.

Precision Build

Machining, assembly, and hardening of wear surfaces.

Validation Package

Measurement reports, spare list, and maintenance guides.

Why Buyers Choose Our Rapidaccu

Cycle-time Oriented Design

We reduce handling and rework steps to keep your takt time stable.

Repeatability First

Stable locating strategies beat “tight machining” alone every time.

Fast Iteration

Design changes happen—our agile process is built to accommodate them.

Clean Documentation

Complete data packages ready for supplier audits and immediate line handover.

What We Need to Quote & Start

“If you’re unsure, send what you have—we’ll propose the safest plan for your specific application.”

Tooling Frequently Asked Questions

What’s the typical lead time for automotive fixtures?

Can you design fixtures for mixed-model production lines?

Do you provide try-out and run-off validation before shipment?

How do you ensure repeatability and avoid part deformation?

Can you build checking fixtures aligned with GD&T?

How do you handle engineering changes (ECN/ECR)?

Ready to stabilize your line?

Send your drawing and current pain points. We’ll reply with a DFM + locating strategy and a comprehensive quote within 24 hours.

Email Us Directly

info@rapidaccu.comGlobal Manufacturing Support

Quick turnaround for automotive hubs worldwide.

Request Quote / DFM Review

Upload your STEP/PDF files for an immediate engineering assessment.