Optical & Photonics Fixtures & Jigs Manufacturer

Precision tooling engineered for repeatable alignment, angular stability, and surface-safe handling. Built for lenses, prisms, fiber assemblies, and laser modules.

Built for Real Optical Failure Modes

Optical tooling rarely fails because it can’t “hold the part.” It fails because it causes repeatability loss, angular drift after locking, or surface contamination. We design to control the error path.

Repeatability Loss

First build aligns, second build drifts.

Tilt/Angle Drift

Lock changes the optical axis.

Surface Damage

Scratches, marks, or dust.

Measurement Bias

Inconsistent holding methods.

The Rapidaccu Solution

Our fixtures focus on “Seat first, constrain second” logic. We ensure forces go exactly where they should, minimizing induced stress and maintaining micron-level posture even under tightening loads.

What Breaks Performance—and How We Prevent It

Consistent Alignment

Strategy: Datum-driven locating that forces errors to converge on references.

- Stable seating before constraint

- Controlled contact points

Angle/Coaxial Stability

Strategy: Locking strategies that minimize tilt shift during fastening.

- Anti-vibration structures

- Thermal-drift-aware materials

Surface Integrity

Strategy: Controlled contact geometry and surface-safe protected interfaces.

- Replaceable wear elements

- Dust-trap-free geometry

Optical & Photonics Tooling We Build

Optical Assembly Jigs

Stabilizing lenses, mirrors, and fiber components during bonding and curing.

- Poka-Yoke Orientation

- Surface-Safe Pads

Optical Polishing Fixtures

Built to control pressure distribution and posture repeatability during cycles.

- Support Mapping

- Residue-Aware Design

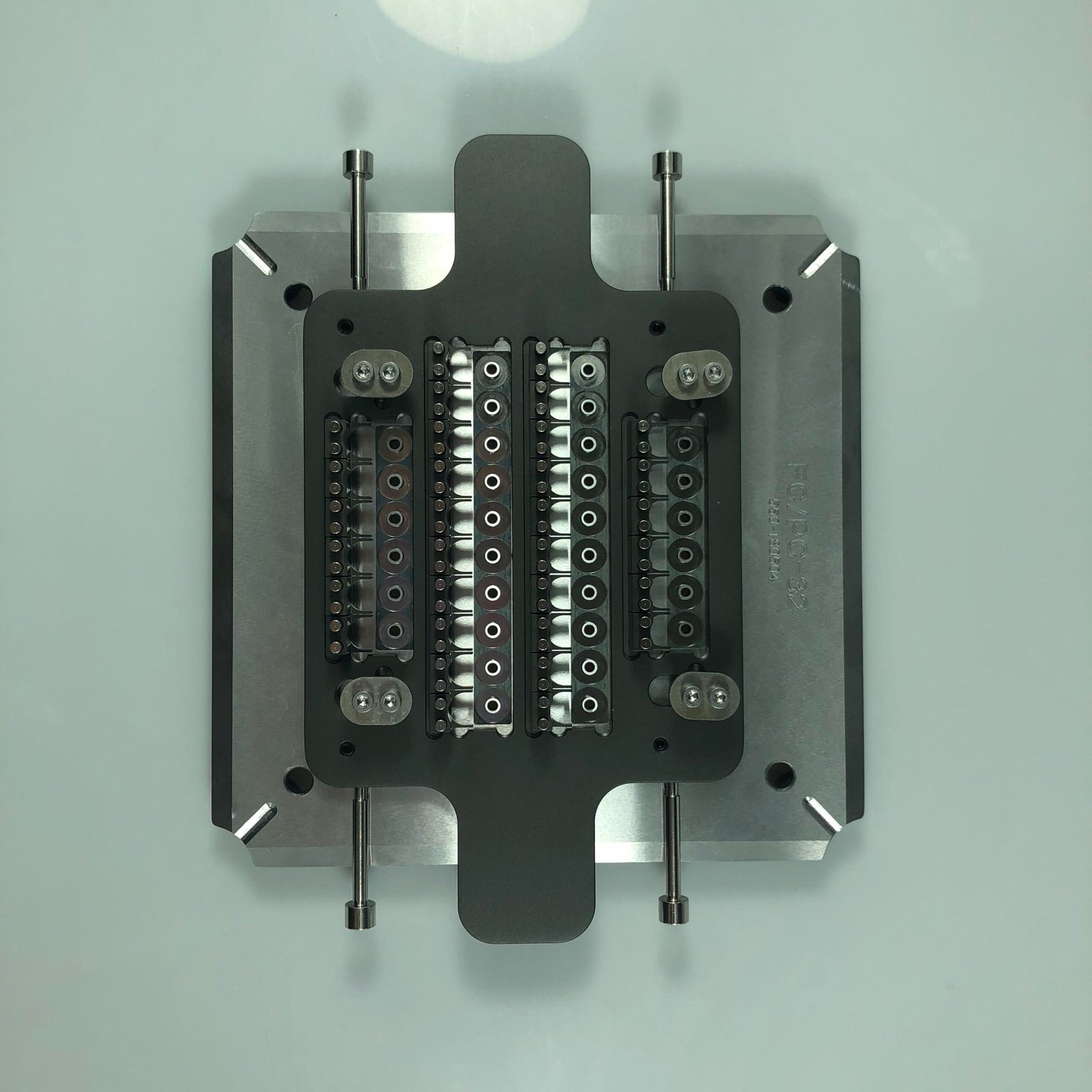

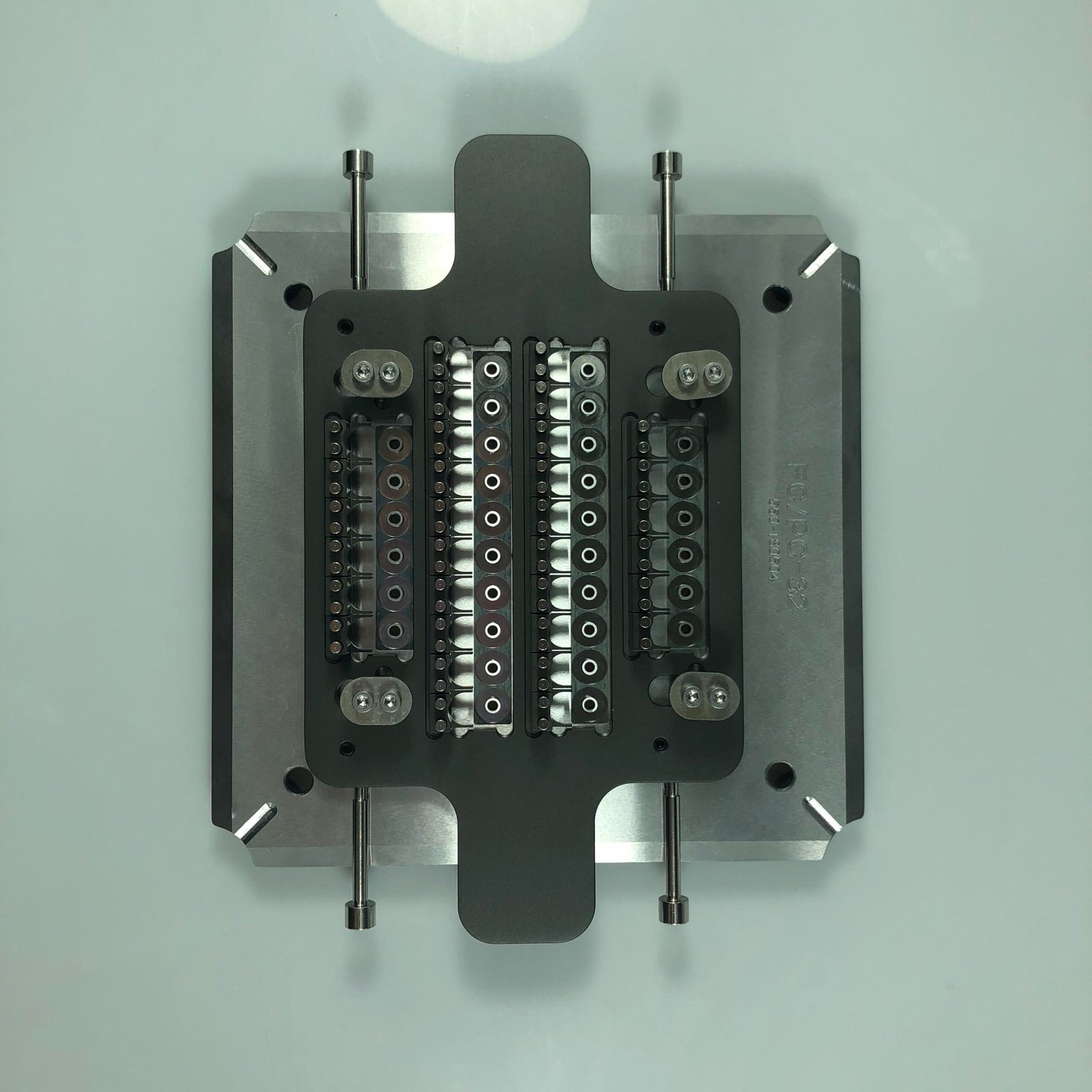

Fiber Polishing Fixtures

Micron-level consistency for fiber end-face processing and chip protection.

- Repeatable Seating

- Ergonomic Handling

Advanced Custom Tooling

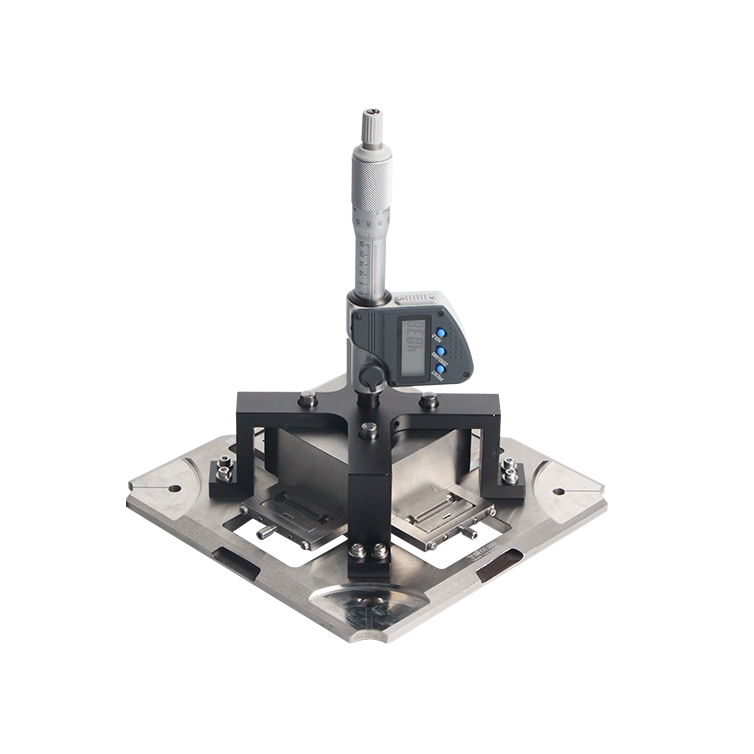

Alignment & Calibration

Micro-adjust and lock strategy (adjust precisely, lock without shift).

Optical Vacuum Fixtures

Safe holding for thin, delicate, or warp-prone components.

Metrology & Inspection

Fixtures for repeatable CMM, vision, and interferometry postures.

Capabilities (So You’re Not Buying “Just a Fixture”)

Locating Strategy

Error-path control, load path analysis, and deformation risks.

Detail Design

Replaceable wear surfaces and modular swappable interfaces.

Precision Mfg

Manufacturing for critical references and locating features.

Metrology Support

Measurement repeatability approach to align inspection workflows.

Our Optical Tooling Process

Review & Proposal

Risk review (repeatability, tilt drift, surface damage) + locating strategy proposal.

Precision Detail Design

Tolerance stack-up analysis, wear part selection, and Poka-Yoke integration.

Build & Validation

Precision build followed by try-out validation for repeatability and lock-stability.

Why Buyers Choose Rapidaccu

Stability First

We design for “hold accurately and stay stable,” not just clamping power.

Yield Mindset

Optical faces are treated as yield-critical zones throughout the design phase.

Modular Architecture

Fast iteration and ECO-friendly workflow without rebuilding the entire base.

What We Need to Quote & Start

If you’re missing information, send what you have—we’ll propose a safe concept first.

Upload Drawing / Request ReviewOptical Tooling FAQ

What repeatability can you achieve for optical fixtures?

How do you prevent angle drift after tightening?

When should we use vacuum fixtures for optical components?

How do you avoid scratches and contamination?

Stabilize Your Optical Axis

Send your drawings and tell us the step that must stay stable (alignment / polishing / assembly / metrology). We’ll respond with an Alignment Risk Review.

Email Us

info@rapidaccu.comService

Global precision manufacturing & support.

Request Alignment Concept

Secure document handling & rapid technical review guaranteed.