- Home ›

- Custom Heat Sink

Custom Heat Sink Solutions

Engineered thermal management systems designed precisely for your application. From concept to production, Rapidaccu delivers CNC machined heat sinks tailored to your unique specifications with 15 years of manufacturing excellence.

Why Choose Custom Heat Sink Design?

Off-the-shelf solutions rarely meet the precise thermal, spatial, and performance requirements of modern electronics. Custom engineering unlocks optimal cooling efficiency.

Perfect Fit

Engineered to exact dimensional constraints, mounting patterns, and interface requirements specific to your product design.

Optimized Performance

Thermal analysis and fin optimization ensure maximum heat dissipation within your power budget and airflow conditions.

Cost Efficiency

Eliminate over-engineering and material waste. Pay only for the thermal capacity you need with optimized designs.

Competitive Edge

Differentiate your products with superior thermal management, enabling higher performance and reliability.

Advanced CNC Capabilities

Rapidaccu’s Shenzhen facility houses cutting-edge CNC machining centers capable of producing complex heat sink geometries with exceptional precision. Our 15-year track record in thermal solutions spans prototyping to high-volume production.

Extrusion Profiles

Cost-effective solutions for high-volume production with standard and custom profiles

Bonded Fin Design

Maximum surface area without tooling investment for high-power applications

Heat Pipe Integration

Advanced thermal transfer for challenging layouts and remote heat dissipation

From Concept to Delivery

A streamlined engineering and manufacturing workflow ensures your custom heat sink meets specifications and deadlines

Requirements Analysis

Share your thermal requirements, space constraints, power dissipation, airflow conditions, and mounting specifications.

Engineering Design

Our team creates 3D CAD models, performs thermal simulation, and optimizes geometry for manufacturing efficiency.

Prototyping

Rapid CNC prototyping allows physical testing and design validation before committing to production tooling.

Production

Scalable manufacturing from low-volume to mass production with consistent quality control and inspection protocols.

Optimized Materials for Every Application

Material choice significantly impacts thermal performance, weight, cost, and manufacturability

Aluminum Alloys

- Lightweight and cost-effective for most applications

- 6063-T5 and 6061-T6 for extrusion and machining

- Excellent corrosion resistance with anodizing

Copper

- Superior conductivity for high-power applications

- Pure copper C11000 or oxygen-free variants

- Ideal for compact designs and extreme heat loads

Hybrid Solutions

- Copper base plates with aluminum fins

- Balances thermal performance and weight/cost

- Heat pipe integration for extended reach

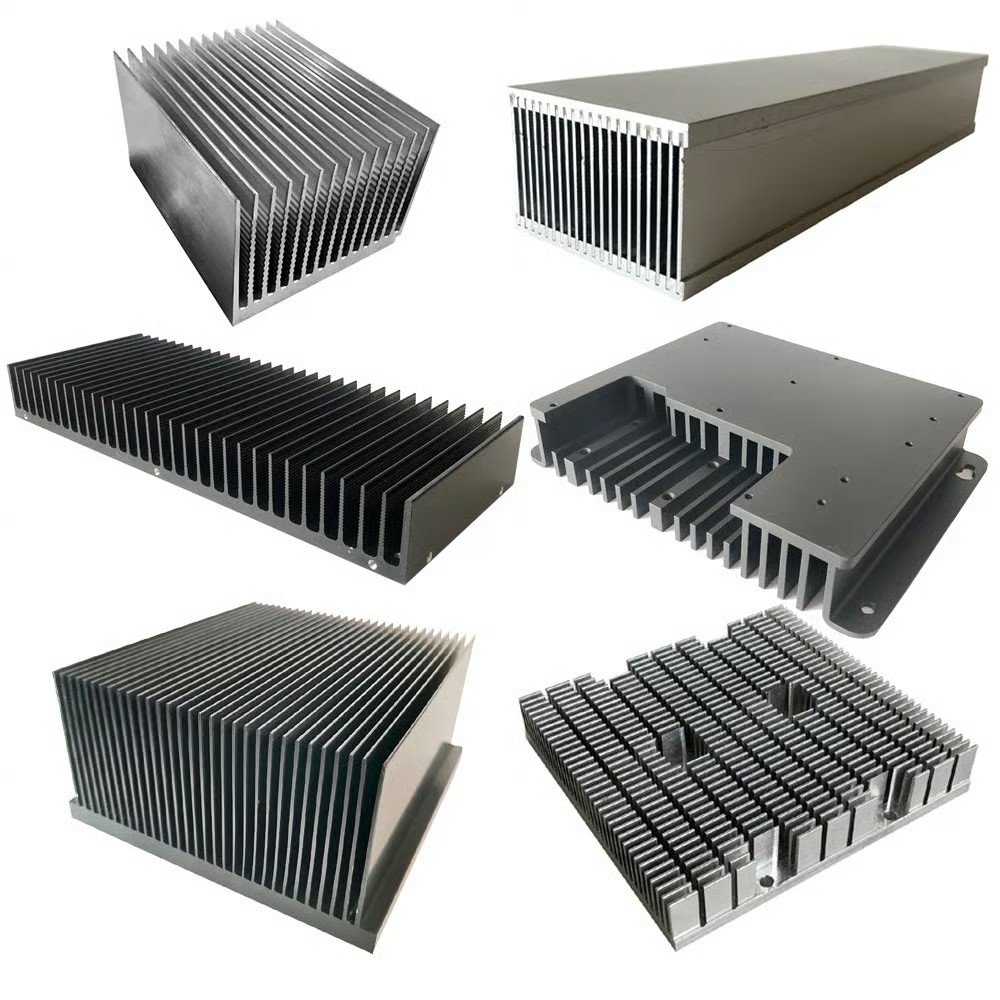

Custom Heat Sink Portfolio

Wide Profile Heatsinks

10mm to 1000mm widths with custom fin patterns for diverse thermal requirements

Precision Extruded Solutions

6063-T5 aluminum with CNC post-processing for exact dimensional control

Surface Treatment Options

Black anodizing, clear anodizing, chemical polishing, and custom finishes

High Efficiency Designs

Optimized fin spacing and geometry for maximum natural or forced convection

Complex Geometries

Multi-axis machining enables intricate cooling patterns and features

Large Surface Area

Dense fin arrays and extended surfaces for maximum heat transfer

Need a Thermal Solution?

Our engineering team is ready to transform your thermal challenges into optimized heat sink designs. With 15 years of experience and state-of-the-art CNC capabilities, we deliver precision solutions on time.

Frequently Asked Questions

What information do I need to provide for a custom heat sink design?

Can you perform thermal simulation before manufacturing?

What is the typical lead time for custom heat sink prototypes?

Do you offer DFM feedback on existing heat sink designs?

What surface finishes are available for custom heat sinks?

Can you manufacture heat sinks with embedded heat pipes?

Start Your Custom Project

Connect with our engineering team to discuss your thermal management requirements

Contact Rapidaccu

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

15 years specializing in precision CNC machining and thermal management solutions

Engineering Support Includes:

- 3D CAD modeling and technical drawings

- Thermal simulation and performance validation

- Material selection guidance

- DFM optimization recommendations

- Prototype fabrication and testing support