- Home ›

- Chip Heat Sink

Chip Heat Sink Solutions

Engineered miniature thermal management for semiconductor chips, processors, and electronic components. Our precision-manufactured chip heat sinks deliver exceptional cooling performance in the smallest form factors for modern electronics.

What is a Chip Heat Sink?

A chip heat sink is a miniature thermal dissipation device specifically designed for cooling semiconductor chips, integrated circuits, and electronic components. These compact cooling solutions are essential in modern electronics where components generate significant heat in extremely small packages.

Unlike larger heat sinks used for CPUs or power devices, chip heat sinks must deliver effective cooling within dimensional constraints as small as 10x10mm. They employ optimized fin geometries, high thermal conductivity materials, and specialized mounting methods to maximize heat transfer in minimal space.

Our chip heat sinks are precision-machined to achieve the tight tolerances required for reliable thermal contact with delicate semiconductor packages, ensuring optimal performance while protecting sensitive components.

Key Specifications

- Size range: 10x10mm to 50x50mm

- Height: 5mm to 30mm profiles

- Materials: Aluminum, Copper, Brass

- Thermal: 0.5-5.0°C/W resistance

Popular Applications

- LED Modules

- Chipset Cooling

- PCB Components

- Transistor Modules

Chip Heat Sink Product Portfolio

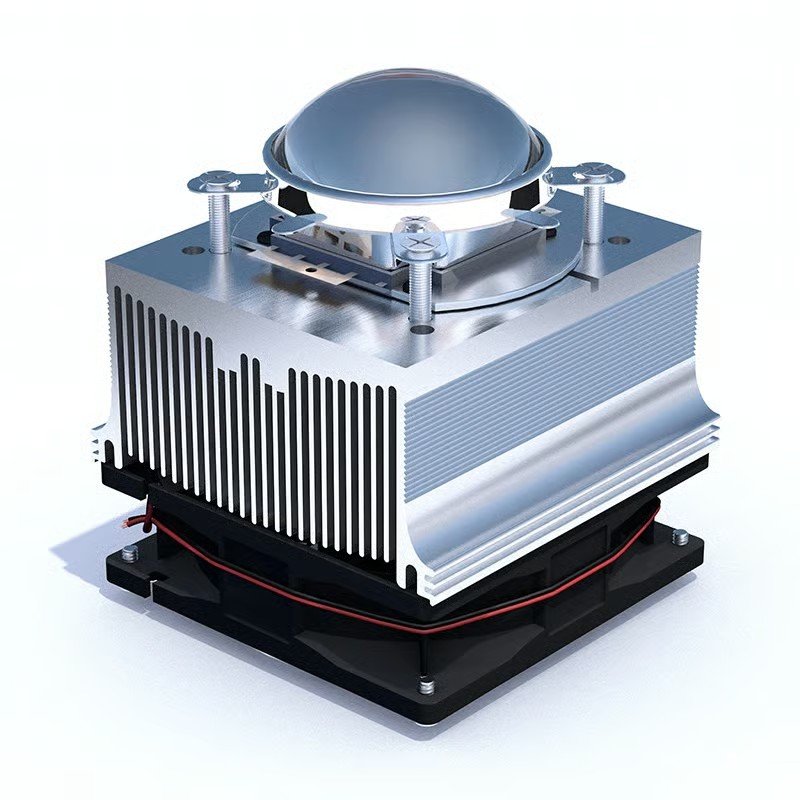

LED Chip Coolers

Aluminum heatsinks for LED modules and transistors with optimized thermal performance.

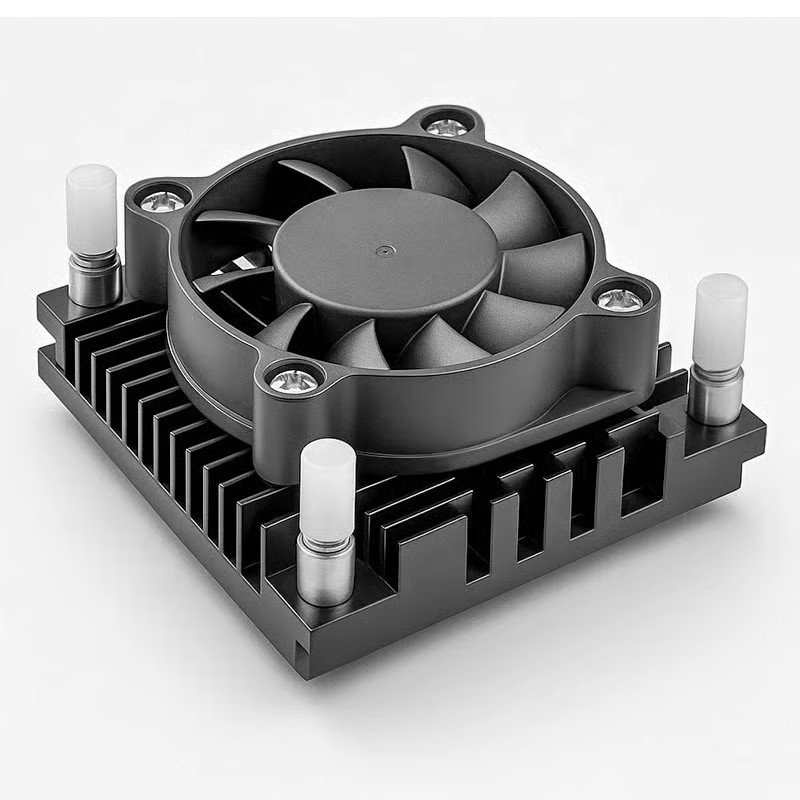

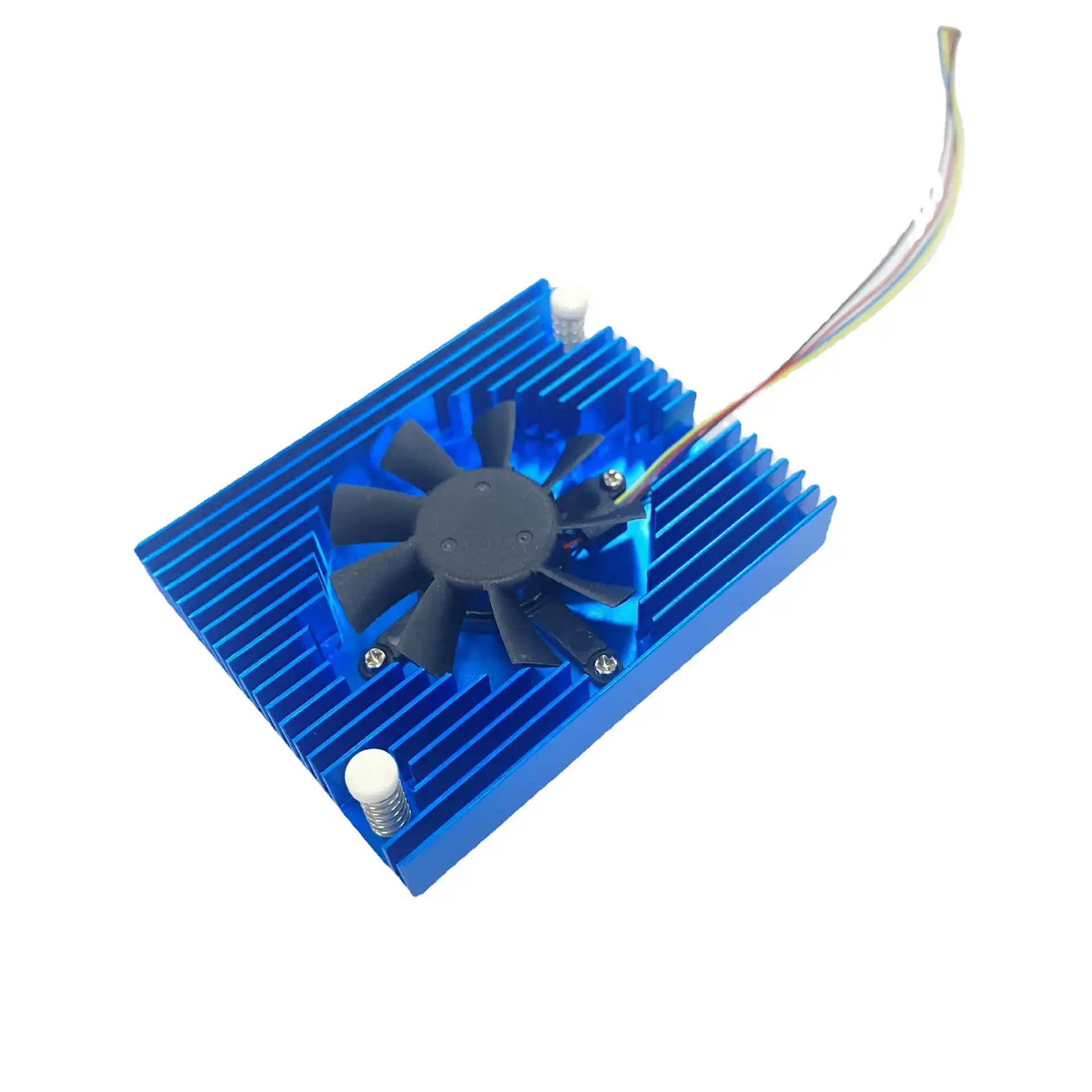

Chipset Solutions

North and South Bridge heat sinks with integrated fan cooling for motherboard chipsets.

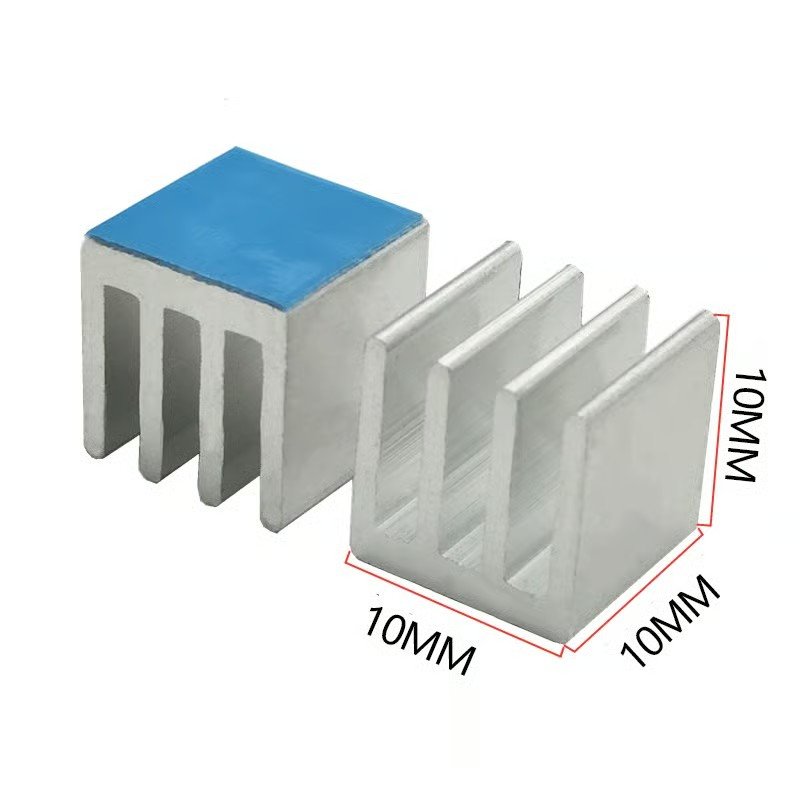

Micro Components

10x10x10mm miniature heatsinks for compact electronic applications.

Semiconductor Coolers

Cold forged aluminum fin heatsinks for semiconductor and chipset applications.

Active Cooling

Fan-integrated heatsinks for high-power chip applications requiring forced convection.

Anodized Finishes

Black anodized aluminum chipset heatsinks with enhanced thermal emissivity.

PCB Mounting

PCB heat sinks for transistors and LED modules with thermal adhesive mounting.

Custom Designs

Fully customized chip heatsinks tailored to specific component requirements.

Design & Manufacturing Excellence

Precision engineering and advanced manufacturing techniques ensure optimal thermal performance

Precision Tolerances

CNC machining achieves base flatness within 0.02mm ensuring optimal thermal contact with chip packages.

Optimized Fin Arrays

High-density fin patterns maximize surface area while maintaining manufacturability and structural integrity.

Surface Treatments

Multiple finish options including anodizing, plating, and coating for enhanced performance and protection.

Technical Advantages

Lightweight

Minimal weight impact on delicate PCBs and components

Compact

Fits within tight space constraints of modern electronics

Efficient

High thermal conductivity materials maximize heat transfer

Easy Mount

Multiple mounting options for simplified assembly

Cost-Effective

Economical thermal solution for volume production

Industry Applications

LED Lighting

High-power LED arrays, COB modules, and lighting fixtures requiring efficient thermal management.

Computer Hardware

Motherboard chipsets, graphics cards, memory modules, and embedded system components.

Mobile Devices

Smartphones, tablets, and portable electronics with miniature component cooling needs.

Telecommunications

Network equipment, routers, switches, and communication device processors.

Automotive Electronics

Engine control units, infotainment systems, and ADAS component cooling.

Industrial Control

PLCs, sensors, controllers, and automation systems in harsh environments.

Frequently Asked Questions

What size chip heat sink do I need for my application?

How do I attach chip heat sinks to components?

When should I use aluminum versus copper chip heat sinks?

Can chip heat sinks be used on PCBs without damaging boards?

What surface finish is best for chip heat sinks?

Do you offer custom chip heat sink designs?

Ready to Enhance Your Component Cooling?

Partner with Rapidaccu for precision chip heat sinks engineered to protect your most critical electronic components.

Request Engineering SupportGet Your Custom Quote

Contact Rapidaccu

Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

15 Years of Precision CNC Manufacturing

Rapidaccu Advantages

- Advanced CNC machining precision

- 15 years thermal solution expertise

- Custom design capabilities

- Rigorous quality control

- Global shipping solutions