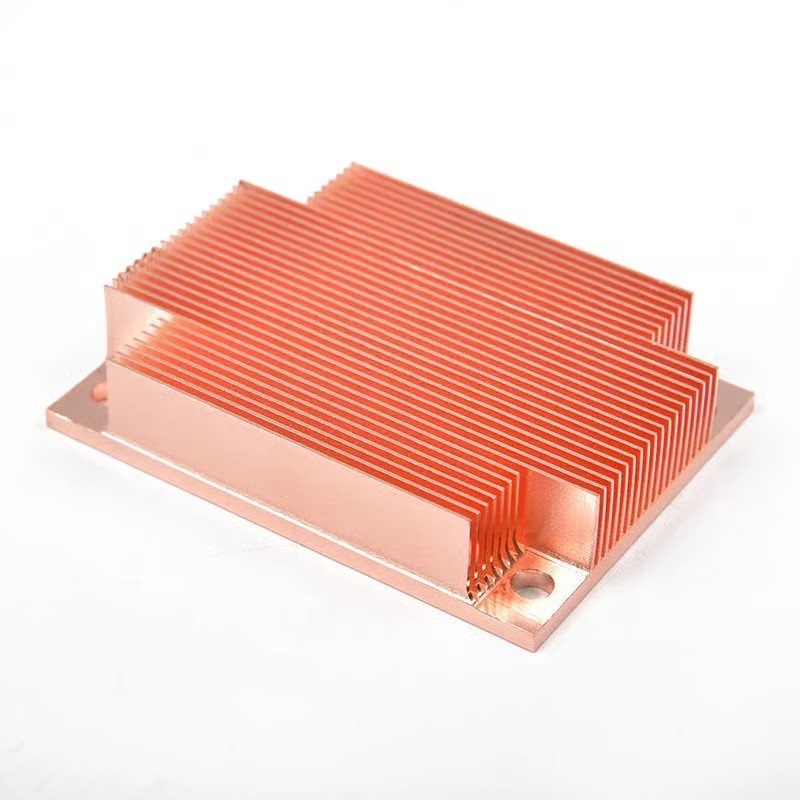

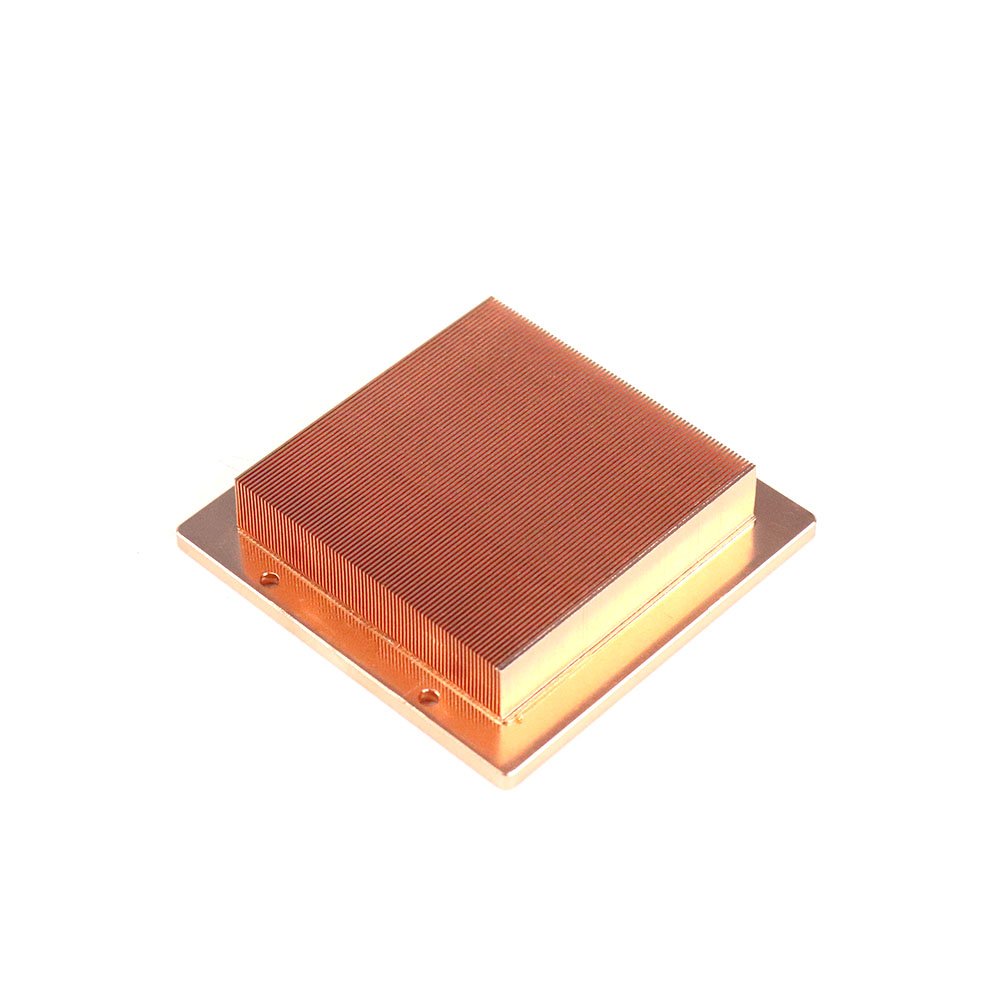

Folded Heat Sink

Innovative folding technology creating exceptional surface area and thermal efficiency for demanding applications

Folding Process Excellence

Folded fin heat sinks utilize precision bending to create high-density fin arrays from continuous metal sheets, achieving superior thermal performance with minimal material waste

High Density

Continuous folding creates maximum fin count per unit area

Material Efficient

Minimal waste compared to machining or stamping processes

Flexible Design

Custom fold patterns for optimized airflow and cooling

Product Portfolio

Aluminum Folded Fin

High efficiency cooling solution

Hybrid Design

Combined folded and stacked fins

Large Format

800mm folded fin heatsink

Technical Specifications

Material Options

Aluminum 1100, 6063, copper C1100, brass for thermal optimization

Sheet Thickness

0.1mm to 2.0mm depending on material and application

Fin Height Range

10mm to 150mm custom heights available

Fin Spacing

0.5mm to 5.0mm customizable for airflow requirements

Maximum Length

Up to 1000mm continuous folded fin arrays

Target Applications

Folded fin technology excels in applications requiring high thermal dissipation in compact form factors

LED Lighting

High-power LED strips

Power Supplies

Linear amplifiers

Solar Inverters

Renewable energy

EV Chargers

Fast charging stations

Telecom Systems

Base station cooling

Industrial

Motor drives

Wind Power

Converter systems

Data Centers

Server cooling

Frequently Asked Questions

Q What are the benefits of folded fin over traditional designs?

Q How are folded fins attached to the base?

Q What is the maximum length for folded fin heat sinks?

Q Can folded fins be made from copper?

Q What is the minimum order quantity?

Q Do you provide thermal performance testing?

Start Your Project Today

Get a custom folded fin solution tailored to your requirements

Contact Information

Factory Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comIndustry Experience

15 Years of Manufacturing Excellence