The Science of Spray:

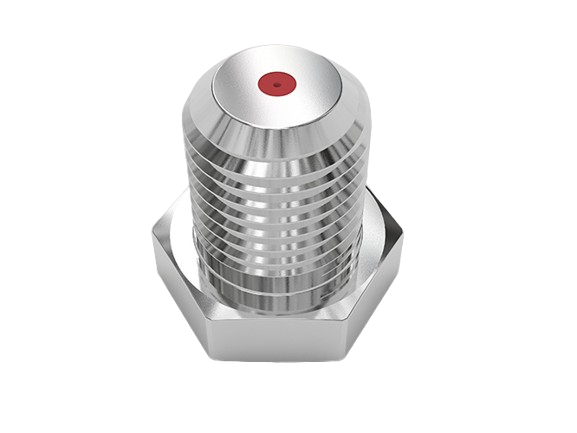

Precision Nozzles for Industry

We don’t just drill holes; we engineer flow. From micron-level atomization to high-impact jetting, discover custom nozzle solutions designed for your specific operating pressure and media.

Why Standard Nozzles Fail Your Process

Off-the-shelf components often compromise on geometry or material compatibility. We solve the hidden causes of spray inconsistency.

Flow Rate Drift

Standard tolerance nozzles wear unevenly, causing flow rate to spike and pressure to drop, disrupting chemical dosing accuracy.

Pattern Collapse

Poor internal finishing leads to turbulence. A “flat fan” becomes a “heavy center” spray, leaving edges unwashed.

Premature Clogging

Inefficient internal flow paths create dead zones where solids accumulate. Our designs optimize velocity to self-clean.

Spray Patterns & Functionality

Flat Fan Nozzles

Linear impact for conveyors & washing.

Solid Stream Nozzles

High impact jet for cutting & deep cleaning.

Hollow Cone Nozzles

Fine atomization for cooling & scrubbing.

Solid Cone Nozzles

Full coverage for quenching & dust control.

Spiral Nozzles

Clog-resistant design for slurry & waste.

Atomizing Nozzles

Micro-droplets for humidity & misting.

Two-Fluid Nozzles

Air-assisted spray for viscous liquids.

Solenoid Valve Nozzles

Electronic On/Off control for automation.

Engineered Materials for Every Environment

Orifice Precision = Process Stability

In industrial spraying, “close enough” is a failure waiting to happen. A 5% deviation in orifice diameter can result in a 10% flow error, wasting expensive chemicals or damaging products.

- 1 CNC micro-machining for consistent atomization.

- 2 In-house flow testing verification.

- 3 Custom thread matching (NPT, BSP, Metric).

Industries We Serve

Frequently Asked Questions

How do I determine the right nozzle size?

Can you manufacture nozzles based on a sample?

Do you have a minimum order quantity (MOQ)?

What thread types do you support?

Start Your Nozzle Project

Whether you need a single replacement prototype or a production run of 10,000 units, our engineering team is ready to review your drawing or application.

Request a Quote

Secure File Upload Supported