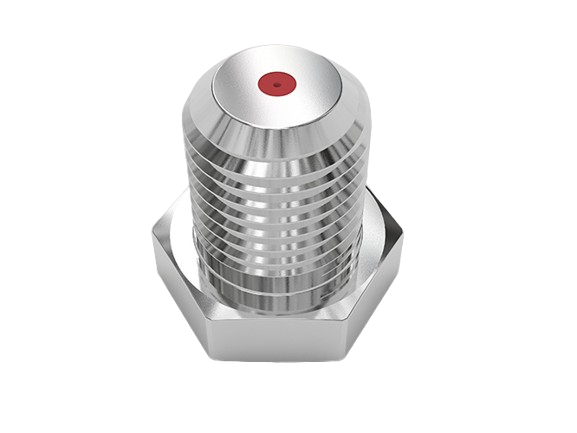

Custom Ruby Nozzles

(Ruby Orifice & Jewel Inserts)

When fluid control depends on micron-level geometry, ruby becomes the performance upgrade. We manufacture custom nozzles where wear, heat, and precision matter more than “just spraying water”.

What Is a Ruby Nozzle?

A “ruby nozzle” typically refers to a jewel-orifice component used to create a highly stable jet through an ultra-precise micro hole. It’s not a commodity part—it’s a precision instrument.

It may be supplied as:

- A standalone ruby orifice insert

- A ruby-orifice nozzle assembly (insert + metal body)

- Micro-drilled insert integrated into valves/manifolds

Wear Resistance

Heat Resistance

Corrosion Resistance

Low Friction

Where Ruby Nozzles Create Value

Targeted applications where performance justifies the material.

Waterjet Cutting

Focus the jet stream for impact and cut quality.

- Stable jet formation

- Predictable cuts

High-Pressure Misting

Generate very fine droplets for cooling/humidification.

- Ultra-fine atomization

- Consistent output

Precision Metering

Integrated into manifolds for precise fluid control.

- Tight flow control

- Repeatable batches

Pulp & Paper

High-wear, high-pressure solid stream trimming.

- Improved lifespan

- High-wear resistance

Engineering Variables That Decide Performance

Orifice Diameter (Micro Hole)

Ruby orifice holes can range from very small micro sizes (0.10 mm) to larger custom holes. The diameter defines flow rate and pressure drop precisely.

Inlet Profile & Edge Quality

A stable jet requires the right inlet geometry and burr-free edge finishing. Micro-machined jewel orifices ensure consistent roundness.

Alignment Inside Body

Proper alignment of the jewel orifice inside the assembly is critical for performance and component life, especially in high-pressure systems.

Media Condition

Service life depends on abrasives. While ruby is hard, improper filtration or extreme abrasives can still impact longevity.

Custom Made to Your Requirements

Rapidaccu supports made-to-order designs. We don’t just sell parts; we engineer solutions.

Customizable Elements

- Ruby orifice ID / inlet type / thickness

- Insert geometry (press-fit / swaged / bonded)

- Body material: SS / Brass / Alloys

- Thread: NPT / BSPT / Custom

- Style: Insert only or Assembly

Why Rapidaccu?

Ruby nozzles are a hybrid precision product: gemstone insert + engineered housing.

- 15+ years CNC machining experience for tight-tolerance housings.

- Strong capability for hard-to-machine alloys (heat/corrosion).

- DFM support to reduce leakage risk and improve fit-up.

- From prototype validation to repeat supply consistency.

Is a Ruby Nozzle Right for You?

Choose Ruby When:

- Long-lasting orifice under wear & high pressure

- Very stable jet / tight flow control

- Chemical resistance & low friction

- Consistent nozzle-to-nozzle output

Considerations:

Ruby may not be ideal when:

- Extreme abrasive conditions without proper inlet

- Ultra-critical cutting needing diamond longevity

Share your conditions, we’ll recommend the solution.

Frequently Asked Questions

What’s the difference between ruby and sapphire orifice nozzles?

Can you make ruby nozzles in non-standard sizes?

Do ruby nozzles work for high-pressure systems?

Can you supply only the ruby orifice insert, not the whole nozzle?

How do I confirm the correct orifice size if I don’t have a drawing?

Get a Custom Ruby Nozzle Quote

To speed up evaluation, please include:

- Application type

- Target pressure & media

- Orifice size requirement

- Drawings or photos