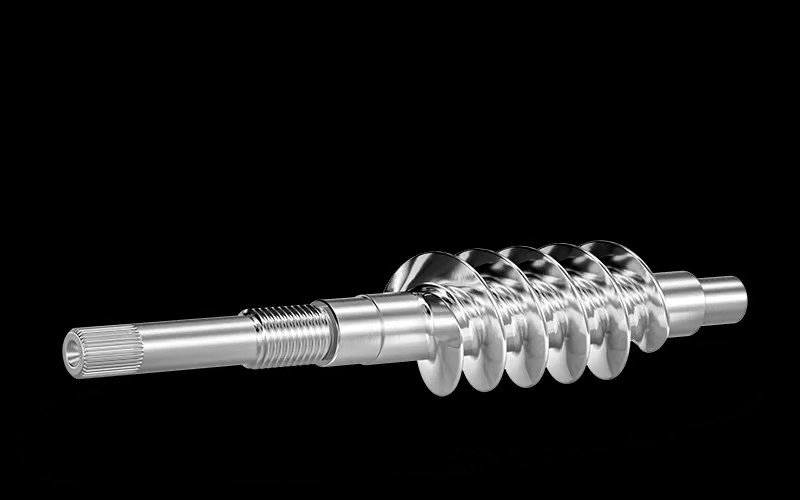

Precision Worm Shaft Manufacturing

Rapidaccu specializes in high-precision worm shaft production for demanding gearbox applications. Our advanced CNC thread milling technology delivers exceptional thread accuracy and surface finish quality.

Understanding Worm Shafts

Worm shafts are cylindrical threaded components that mesh with worm wheels to create compact, high-ratio speed reduction systems. The helical thread profile allows for smooth, quiet operation with self-locking capabilities, making worm drives ideal for applications requiring high torque multiplication and irreversible motion transfer.

Thread Geometry

Precision helical threads machined to exact lead angles and pitch specifications

Speed Reduction

High reduction ratios from 5:1 to 300:1 in compact package sizes

Self-Locking

Inherent back-drive resistance for safety-critical applications

Manufacturing Capabilities

Precision worm shaft production with advanced CNC technology

Diameter Range

0.1″ – 24″

From miniature worm shafts to heavy-duty industrial sizes

Maximum Length

Up to 236″

Extended worm shafts for specialized gearbox designs

Straightness

.0002″

Critical precision for smooth worm gear engagement

Thread Specifications

Lead Angles

2° – 45°

Modules

0.5 – 20

Starts

1 – 4

Accuracy

DIN 5-7

Advanced CNC Thread Milling

Our state-of-the-art CNC thread milling technology produces worm shafts with exceptional thread accuracy and consistency. This advanced process ensures precise lead angles, optimal surface finish, and superior dimensional control.

CNC Thread Milling

Multi-axis interpolation for complex thread profiles and lead variations

Thread Grinding

Precision grinding for hardened worm shafts achieving DIN quality grade 5

Shaft Machining

Integrated turning, drilling, and keyway cutting in single setup

Forging & Material Processing

Forged worm shaft blanks provide enhanced mechanical properties and grain flow alignment. Our comprehensive heat treatment capabilities ensure optimal hardness and wear resistance for long service life.

Carburizing

Case hardening for wear-resistant thread surfaces

Induction Hardening

Selective hardening of thread profiles

Nitriding

Surface hardening with minimal distortion

Through Hardening

Uniform hardness throughout shaft body

Worm Shaft Configurations

Custom designs for diverse gearbox applications

Single Start Worms

Single thread helix providing maximum reduction ratios and self-locking properties.

- Ratios up to 100:1

- Self-locking capability

- Compact gearbox design

Multi-Start Worms

Multiple thread starts for higher speeds and improved efficiency in high-performance applications.

- 2, 3, or 4 start threads

- Higher efficiency

- Faster output speeds

Globoidal Worms

Hourglass-shaped worm profile maximizing contact area for superior load capacity.

- Maximum contact ratio

- Heavy-duty applications

- Enhanced efficiency

Why Choose Rapidaccu

With 15 years of precision manufacturing expertise, Rapidaccu delivers worm shafts that meet the most stringent quality standards for global markets.

Expert Engineering

Specialized knowledge in worm gear geometry and manufacturing processes

Precision Inspection

CMM verification of thread profiles, lead accuracy, and surface finish quality

International Standards

Compliance with DIN, AGMA, and ISO specifications for global compatibility

Reliable Partnership

Dedicated support team ensuring smooth project execution and delivery

Industries We Serve

Worm shaft solutions for diverse applications

Manufacturing

Conveyors & machinery

Automotive

Steering systems

Material Handling

Elevators & hoists

Oil & Gas

Valves & actuators

Renewable Energy

Solar trackers

Water Treatment

Gate operators

Construction

Equipment drives

Automation

Robotic systems

Frequently Asked Questions

Expert answers to common worm shaft questions

What thread profiles are available for worm shafts?

We manufacture worm shafts with various thread profiles including ZA (straight-sided axial), ZN (involute normal), ZI (involute axial), and ZK (archimedean axial) according to DIN 3975. Profile selection depends on load requirements and efficiency targets.

What materials are best for worm shafts?

Common materials include case-hardening steels (4140, 8620), through-hardening steels (4340), and tool steels for high-wear applications. Material selection depends on hardness requirements, load capacity, and mating worm wheel material (typically bronze or cast iron).

What surface hardness is required for worm shafts?

Standard worm shafts require surface hardness of HRC 58-62 for optimal wear resistance when mating with bronze worm wheels. We achieve this through carburizing, induction hardening, or nitriding processes depending on application requirements and shaft size.

Can you grind worm threads after heat treatment?

Yes, we provide precision thread grinding services for hardened worm shafts to correct heat treatment distortion and achieve DIN quality grade 5 accuracy. Our CNC grinding equipment handles single and multi-start worms up to module 12.

What quality inspections are performed on worm shafts?

Comprehensive inspection includes CMM measurement of thread profile accuracy, lead verification, pitch consistency, surface roughness testing, hardness testing, and dimensional verification. Complete inspection reports with material certificates are provided.

Do you offer worm shaft prototyping services?

Absolutely. We provide rapid prototyping for custom worm shaft designs with full machining and heat treatment. Our engineering team assists with design verification and optimization before production runs. Typical prototype lead time is 2-3 weeks.

Explore Our Other Shaft Products

Comprehensive shaft manufacturing solutions for diverse applications

Drive Shaft

Power transmission

Cam Shaft

Valve control

Axle Shaft

Vehicle drive systems

Crank Shaft

Engine power

Motor Shaft

Electric motors

Gear Shaft

Integrated gears

Spline Shaft

Torque transfer

Welded Shaft

Fabricated assemblies

CV Shaft

Constant velocity

Jack Shaft

Intermediate drive

Propeller Shaft

Marine applications

PTO Shaft

Agricultural equipment

Steering Shaft

Automotive steering

Start Your Worm Shaft Project

Contact Rapidaccu today for precision worm shaft manufacturing. Our expert team delivers quality, reliability, and exceptional service for your gearbox requirements.

Factory Address

Rongli Industrial Park, Dalang, Longhua District

Shenzhen, China

Email Us

info@rapidaccu.comOur Experience

15 Years of CNC Machining Excellence

Request Your Quote

Fill out the form below and our team will respond within 24 hours