- Home ›

- 3D Printing ›

- Brass 3D Printing

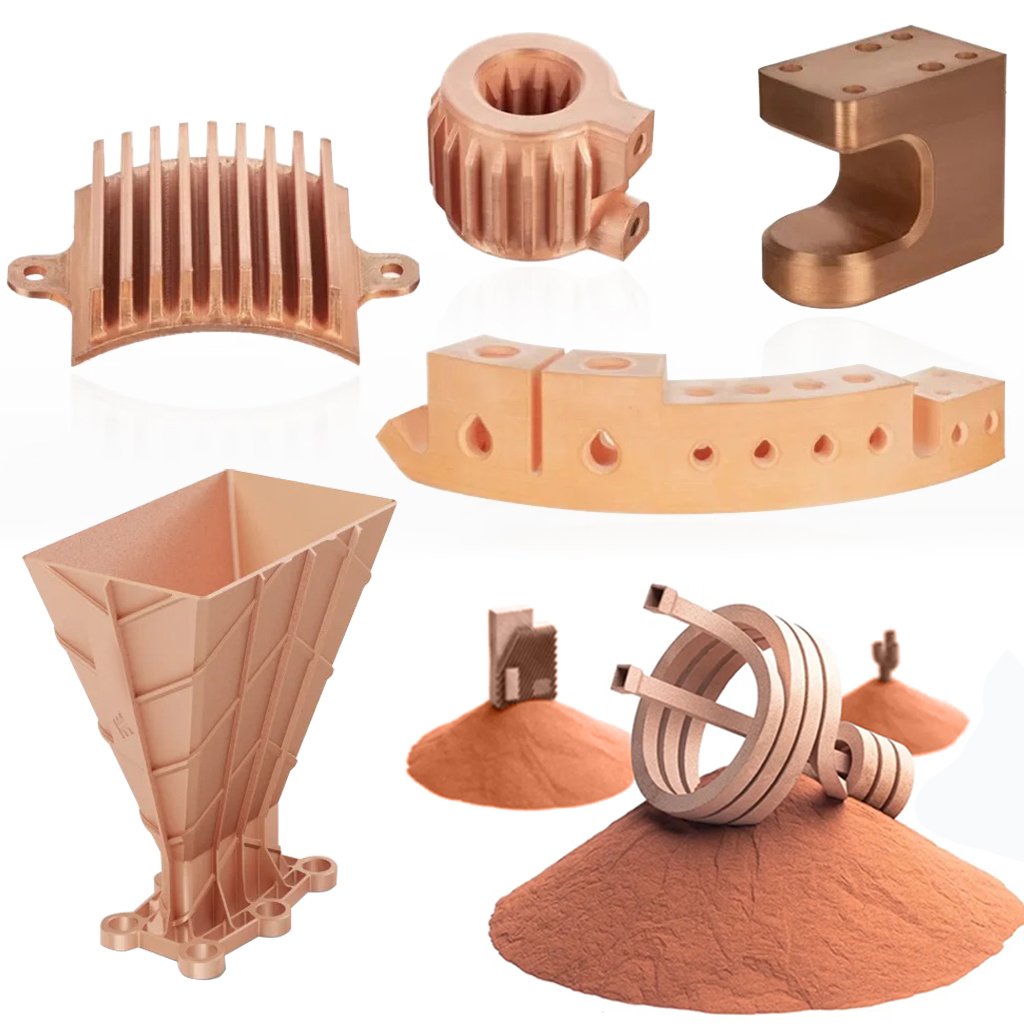

Brass 3D Printing Services

Rapidaccu provides professional brass additive manufacturing with exceptional electrical conductivity, corrosion resistance, and aesthetic appeal. Perfect for decorative hardware, electrical components, musical instruments, and precision mechanical parts.

Start Your Project

Brass Material Excellence

Premium copper-zinc alloy combining beauty with functionality

Aesthetic Appeal

Beautiful golden color perfect for decorative applications, jewelry, architectural elements, and premium consumer products.

Electrical Conductivity

Excellent electrical properties for connectors, terminals, and electronic components requiring reliable conductivity.

Corrosion Resistance

Superior resistance to corrosion, tarnishing, and oxidation for long-lasting marine and outdoor applications.

Excellent Machinability

Easy to machine, polish, and finish for precision components requiring tight tolerances and smooth surfaces.

Acoustic Properties

Ideal for musical instruments with excellent resonance and tonal quality for horns and wind instruments.

Antimicrobial

Natural antimicrobial properties make brass ideal for door handles, medical equipment, and public touchpoints.

15 Years Brass Expertise

Rapidaccu is a premier Chinese metal manufacturer specializing in brass 3D printing. Our advanced Shenzhen facility delivers premium brass components to clients worldwide with certified quality and precision craftsmanship.

Brass Application Industries

Architectural Hardware

Door handles, locks, hinges, fixtures, and decorative architectural elements.

Electrical Components

Connectors, terminals, contacts, and precision electrical parts.

Musical Instruments

Instrument components, valves, keys, and acoustic elements.

Jewelry & Art

Custom jewelry pieces, sculptures, and decorative art objects.

Marine Applications

Boat fittings, marine hardware, and corrosion-resistant components.

Mechanical Parts

Gears, bushings, valves, and precision mechanical components.

Technical Specifications

Premium brass alloys for demanding applications

Material Properties

Common Alloys

C36000 and CuZn37 for excellent machinability

Surface Finish

Polishing, patina, plating, protective coatings available

Wear Resistance

Excellent for bushings, bearings, and sliding applications

Manufacturing Process

Design Consultation

Expert guidance on design optimization for brass additive manufacturing, considering alloy properties and post-processing requirements.

Alloy Selection

Choose optimal brass composition based on application requirements including strength, corrosion resistance, and aesthetic preferences.

Metal 3D Printing

Advanced metal additive manufacturing with precise control over brass powder fusion for complex geometries.

Finishing & Quality

Polishing, plating, patina application, and comprehensive quality inspection with material certification.

Frequently Asked Questions

What brass alloys do you offer for 3D printing?

Can brass parts be polished to a mirror finish?

Is brass suitable for outdoor applications?

What tolerances can you achieve with brass 3D printing?

Can brass be plated or coated?

How does brass compare to bronze for 3D printing?

Request Brass Quote

Partner with Rapidaccu for expert brass 3D printing services. Our metal manufacturing expertise delivers beautiful, functional brass components for your most demanding applications.