- Home ›

- 3D Printing

Professional 3D Printing Services

Rapidaccu delivers precision additive manufacturing solutions across 16 advanced materials. From high-performance plastics to aerospace-grade metals, we bring your designs to life with exceptional quality and reliability.

Our 3D Printing Capabilities

With 15+ years of experience, Rapidaccu produces high-quality parts at competitive prices, from rapid prototypes to functional end parts across multiple advanced 3D printing technologies.

FDM

Fast & Affordable Prototyping

Dimensional accuracy of ± 0.5% (minimum ± 0.5 mm)

Lead times from 1 business day

SLS

Functional Prototyping & Production

Dimensional accuracy of ± 0.3% (minimum ± 0.3 mm)

Lead times from 3 business days

MJF

Functional Prototyping & Production

Dimensional accuracy of ± 0.3% (minimum ± 0.3 mm)

Lead times from 3 business days

SLA

Visual Prototyping

Dimensional accuracy of ± 0.3% (minimum ± 0.3 mm)

High-resolution surface finish

Why Choose Rapidaccu 3D Printing

Industry-leading additive manufacturing with uncompromising quality standards

16 Materials

Comprehensive selection of engineering plastics and metals

Quality Certified

ISO certified manufacturing with rigorous quality control

15+ Years Expertise

Proven track record in precision manufacturing

Global Shipping

Worldwide delivery from Shenzhen, China

Available 3D Printing Materials

Select from our comprehensive range of engineering-grade plastics and high-performance metals

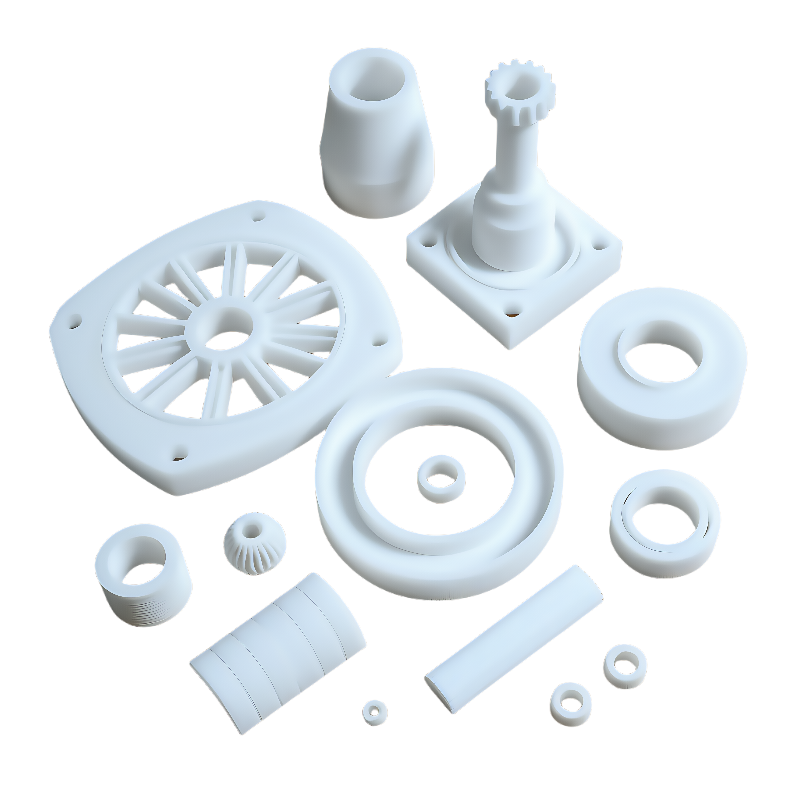

Engineering Plastics

POM

Polyoxymethylene – Low friction, high stiffness

Acrylic (PMMA)

Transparent, excellent optical clarity

ABS

Impact resistant, durable thermoplastic

HDPE

Chemical resistant, food-safe grade

Nylon (PA)

High strength, abrasion resistant

PEI (ULTEM)

High-temp, aerospace certified

PET

Recyclable, food-grade available

Polypropylene (PP)

Flexible, living hinge capability

Polystyrene (PS)

Rigid, excellent surface finish

PVC

Flame retardant, weather resistant

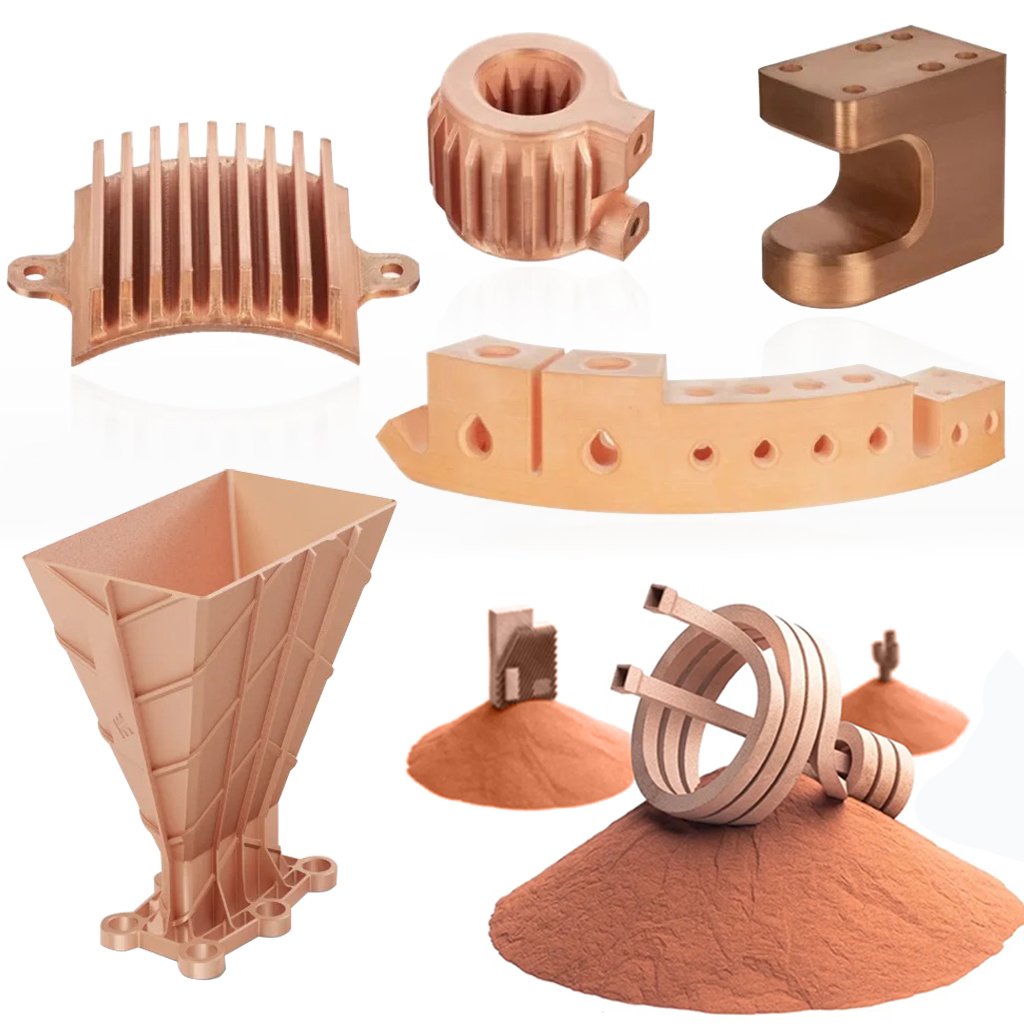

High-Performance Metals

Aluminum

Lightweight, excellent strength-to-weight

Brass

Decorative finish, good machinability

Copper

Superior thermal/electrical conductivity

Stainless Steel

Corrosion resistant, biocompatible

Titanium

Aerospace grade, biocompatible

Inconel

Extreme temp superalloy, turbines

Our Manufacturing Capabilities

Advanced technology and expertise for complex parts production

Complex Geometries

Design freedom impossible with traditional manufacturing. Internal channels, lattice structures, and organic shapes.

Precision Tolerances

Achieve tight tolerances down to ±0.1mm with advanced calibration and post-processing capabilities.

Flexible Volumes

From single prototypes to medium-volume production runs. No minimum order quantity.

Industries We Serve

Trusted by leading companies across diverse sectors

Aerospace

Lightweight components, turbine parts

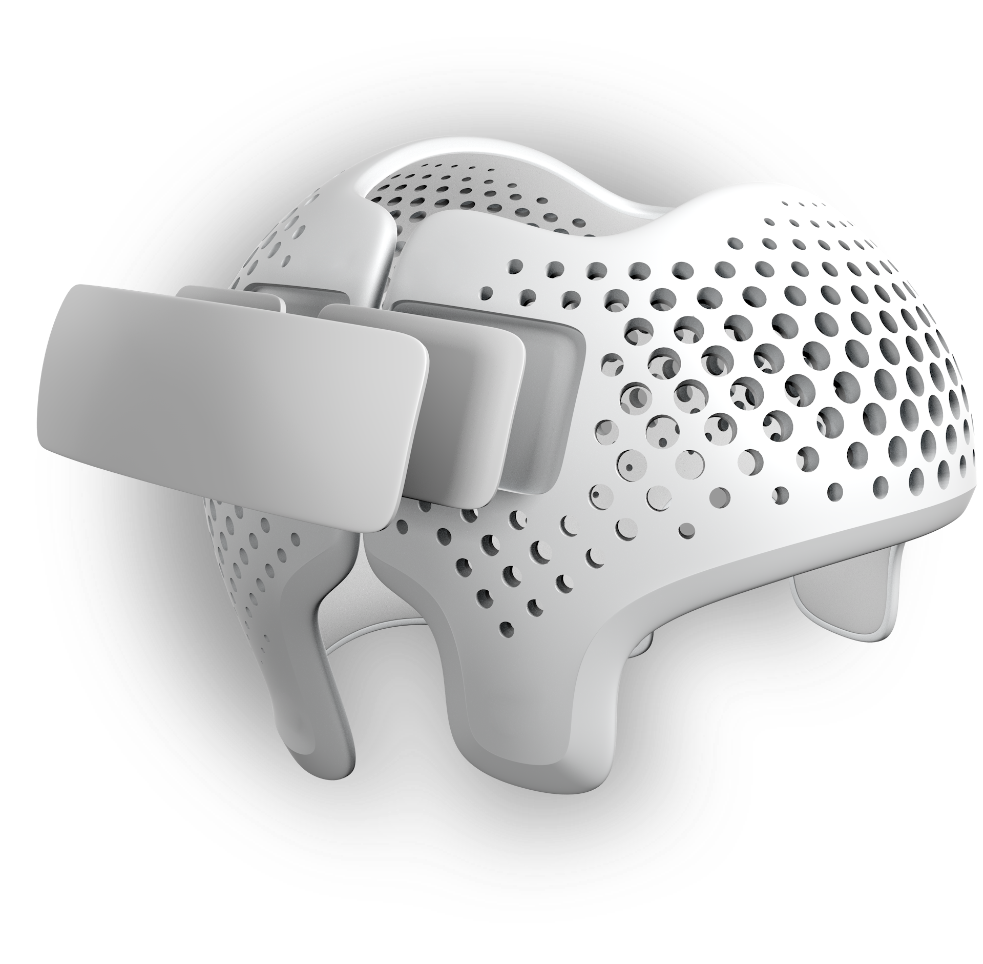

Medical

Surgical instruments, implants

Automotive

Prototypes, custom parts

Electronics

Housings, heat sinks, connectors

Robotics

End effectors, lightweight frames

Energy

Heat exchangers, manifolds

Chemical

Corrosion-resistant equipment

Industrial

Tooling, jigs, fixtures

Ready to Start Your Project?

Get expert guidance on material selection and manufacturing for your specific application

Our Location

Rongli Industrial Park, Dalang

Longhua District, Shenzhen, China

Get in Touch

info@rapidaccu.comRequest a Quote

Frequently Asked Questions

Common questions about our 3D printing services