SLS 3D Printing

No Support Required

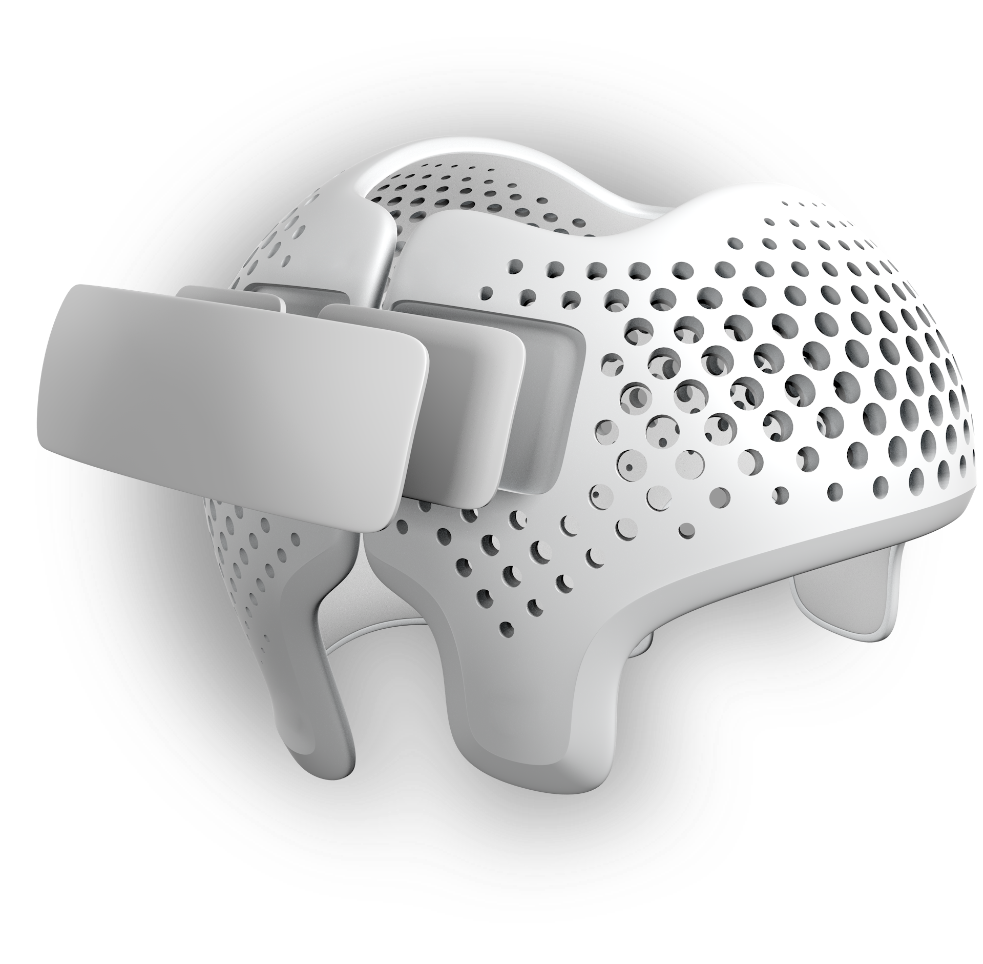

Rapidaccu’s SLS (Selective Laser Sintering) 3D printing service delivers high-strength functional prototypes and end-use parts without support structures. Perfect for complex geometries, nested assemblies, and production-grade components with superior mechanical properties.

What is SLS 3D Printing?

Selective Laser Sintering (SLS) is an advanced additive manufacturing technology that uses a high-powered laser to fuse powdered material layer by layer. Unlike other 3D printing processes, SLS does not require support structures as the unsintered powder bed supports the part during printing.

This support-free process enables the production of complex geometries, interlocking parts, and intricate internal channels that would be impossible or impractical with traditional manufacturing methods. The result is strong, functional parts with consistent mechanical properties throughout.

Layer-by-Layer

Laser precisely fuses powder material in thin layers

No Supports

Powder bed provides natural support structure

Production Quality

Strong parts suitable for functional testing and end-use

SLS Material Options

Rapidaccu offers a comprehensive range of SLS materials optimized for various applications, from functional prototypes to end-use production parts

Nylon PA12

Most popular SLS material. Strong, durable, and excellent chemical resistance. Ideal for functional prototypes and end-use parts.

Nylon PA11

Bio-based polyamide with excellent impact resistance and flexibility. Superior elongation at break compared to PA12.

PA12-FR (Flame Retardant)

UL94 V-0 rated flame retardant nylon. Essential for aerospace, automotive, and electronics applications requiring fire safety.

PA12-GF (Glass Filled)

40% glass fiber reinforced nylon. Exceptional stiffness and strength-to-weight ratio. Ideal for structural components.

TPU (Elastomer)

Flexible thermoplastic polyurethane with rubber-like properties. Shore A 92 hardness. Perfect for gaskets and flexible parts.

Polypropylene (PP)

Lightweight with excellent chemical resistance. Low moisture absorption. Suitable for functional prototypes and chemical environments.

Technical Specifications

Build Specifications

Surface Finish

As-printed: Slightly grainy texture (Ra 6-10 μm). Post-processing options include vapor smoothing, dyeing, painting, and bead blasting for improved aesthetics.

Color Options

Standard: White, black, gray. Custom colors available through dyeing process. Consistent color throughout part thickness.

Quality Certifications

ISO 9001:2015 certified facility. AS9100 aerospace certification. FDA and USP Class VI compliant materials available for medical applications.

Why Choose SLS for Your Project?

Selective Laser Sintering offers unique advantages that make it the preferred choice for functional prototypes and production parts

Design Freedom

No support structures required enables complex geometries, undercuts, and interlocking assemblies impossible with other methods

Strong Parts

Isotropic mechanical properties with excellent strength, stiffness, and durability suitable for functional testing and end-use applications

High Packing Density

Multiple parts can be nested in the powder bed, maximizing build volume efficiency and reducing per-part costs

Production Ready

Proven for low to medium volume production. Chemical resistant, heat resistant materials suitable for demanding environments

Design Guidelines for SLS

Optimal Design Features

- Minimum wall thickness: 0.7 mm for standard PA12, 1.0 mm for glass-filled materials

- Clearance gaps: Minimum 0.4 mm between moving parts

- Embossed details: Minimum 0.5 mm depth and 0.5 mm width

- Holes and channels: Minimum 2 mm diameter for long channels

- Snap fits: SLS materials excellent for living hinges and snap-fit designs

Design Considerations

- Powder escape: Design hollow parts with drain holes to remove trapped powder

- Warping: Large flat surfaces may warp; add ribs or draft angles for support

- Surface finish: As-printed finish is slightly grainy; consider vapor smoothing for aesthetic parts

- Shrinkage: Parts shrink uniformly approximately 3-4% during cooling

- Material properties: Parts are slightly porous; consider sealing for fluid applications

Pro Tip: Nested Assemblies

One of SLS’s unique advantages is the ability to print fully assembled mechanisms in a single build. Design snap-fit assemblies, hinges, or gear trains that print assembled without needing to remove supports or assemble afterwards. Ensure minimum 0.4mm clearance between moving parts.

Applications & Industries

SLS 3D printing serves diverse industries with demanding functional requirements

Aerospace

Air ducts, brackets, custom jigs and fixtures, lightweight structural components with exceptional strength-to-weight ratios

Automotive

Intake manifolds, custom grilles, mounting brackets, low-volume production parts, functional test components

Medical Devices

Surgical guides, prosthetics, custom housings, sterilizable instruments, biocompatible prototypes

Robotics

Custom housings, gears, structural frames, cable management systems, lightweight yet strong components

Industrial Equipment

Jigs and fixtures, end-of-arm tooling, custom adapters, protective covers, chemical resistant components

Consumer Products

Snap-fit enclosures, custom handles, wearables, sporting goods, fashion accessories, replacement parts

Post-Processing Options

Vapor Smoothing

Chemical vapor process creates glass-smooth surface finish. Improves aesthetics and water resistance. Ideal for consumer-facing parts.

Dyeing

Wide range of colors available for PA12 and PA11 parts. Color penetrates throughout part thickness. Maintains mechanical properties.

Painting & Coating

Professional spray painting or specialty coatings available. Soft-touch, metallic, or matte finishes. Enhances UV resistance.

CNC Machining

Secondary machining for tight tolerances, threads, or smooth mating surfaces. Combines speed of 3D printing with precision of CNC.

Media Blasting

Glass bead blasting creates uniform matte surface. Removes powder residue. Prepares surface for painting or coating applications.

Assembly & Inserts

Heat-set inserts installation for metal threads. Assembly of multi-material components. Bonding with specialized adhesives.

Frequently Asked Questions

What’s the difference between SLS and MJF?

Both are powder bed fusion technologies using nylon materials. SLS uses a laser to fuse powder selectively. MJF uses infrared lamps and fusing agents. MJF typically offers slightly better surface finish and more consistent mechanical properties, while SLS has been proven longer with more material options including glass-filled and flame-retardant grades.

Can SLS parts be used for end-use production?

Absolutely. SLS produces functional parts with mechanical properties suitable for many end-use applications. Parts exhibit isotropic strength, good chemical resistance, and durability. Many industries use SLS for low to medium volume production (typically up to several thousand units) where tooling costs for injection molding would be prohibitive.

Why don’t SLS parts need support structures?

The build chamber is filled with powder that remains loose and unfused during printing. This powder bed naturally supports overhangs, bridging features, and complex geometries. After printing, parts are simply extracted from the powder bed and loose powder is brushed away. This enables design freedom impossible with FDM or SLA processes.

What surface finish can I expect from SLS?

As-printed SLS parts have a slightly grainy, matte surface texture (Ra 6-10 μm) due to the powder particle size. This is acceptable for most functional applications. For improved aesthetics, vapor smoothing creates a glass-smooth finish, or parts can be dyed, painted, or bead blasted. The surface finish is uniform on all sides since no support removal is required.

Are there biocompatible SLS materials?

Yes. PA12 materials meeting USP Class VI and ISO 10993 biocompatibility standards are available for medical device prototyping and some end-use applications. These materials can withstand standard sterilization methods including autoclave, EtO, and gamma radiation. Consult with Rapidaccu’s engineering team for guidance on material selection for medical applications.

How do I prepare my CAD file for SLS printing?

Export your design as an STL or STEP file with a resolution of 0.01mm or finer. Ensure walls are at least 0.7mm thick (1.0mm for glass-filled). Design drainage holes for hollow parts to allow powder removal. No need to add supports or orient for printing – our engineers will optimize placement in the build chamber for best results and cost efficiency.

Get Your SLS Quote Today

Upload your CAD file and receive a detailed quote from our engineering team

Contact Information

What to Include in Your Quote Request:

- CAD files (STL, STEP, or IGES format)

- Desired material and post-processing

- Quantity and any critical dimensions

- Application and functional requirements