- Home ›

- 3D Printing ›

- POM 3D Printing

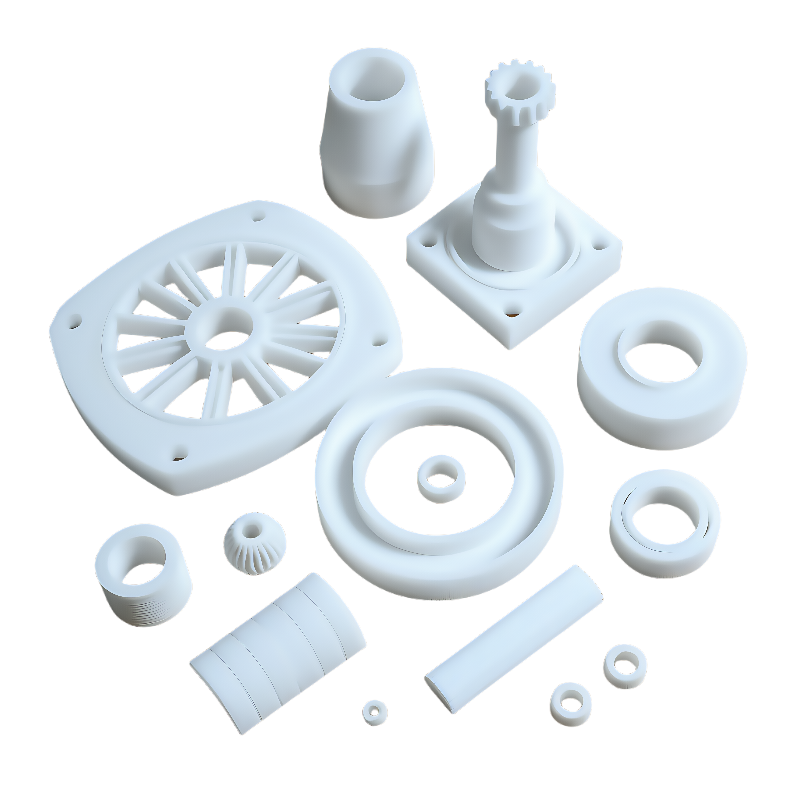

POM 3D Printing Services

Rapidaccu delivers precision POM 3D printing solutions with exceptional dimensional stability, low friction, and high wear resistance. Perfect for mechanical parts requiring tight tolerances and smooth operation.

Request a Quote

Why Choose POM for 3D Printing?

Polyoxymethylene offers unique properties that make it ideal for demanding engineering applications

Excellent Mechanical Properties

High stiffness and strength combined with excellent dimensional stability for precision mechanical components.

Low Friction Coefficient

Natural lubricity makes POM perfect for gears, bearings, and sliding components without additional lubrication.

Chemical Resistance

Excellent resistance to solvents, fuels, and many chemicals, ideal for automotive and industrial environments.

Advanced POM Manufacturing Capabilities

With 15 years of experience, Rapidaccu specializes in manufacturing high-precision POM components using state-of-the-art 3D printing technology. Our facility in Shenzhen, China delivers exceptional quality for international clients.

- Complex geometries with tight tolerances down to ±0.05mm

- Superior surface finish for immediate assembly

- Comprehensive quality inspection and certification

POM 3D Printing Applications

Automotive Components

Fuel system parts, electrical connectors, and interior mechanisms requiring durability and chemical resistance.

Industrial Equipment

Precision gears, bearings, conveyor components, and valve parts for manufacturing machinery.

Consumer Products

Zippers, buckles, snap-fit assemblies, and mechanical toys requiring smooth operation.

Medical Devices

Surgical instrument components and diagnostic equipment parts requiring precision and reliability.

Electronics

Insulating components, precision housings, and connector parts with excellent dimensional stability.

Custom Solutions

Specialized applications requiring POM’s unique combination of properties and precision manufacturing.

Technical Specifications

Our Manufacturing Process

Design Analysis

Our engineering team reviews your specifications to optimize design for POM 3D printing, ensuring manufacturability and performance.

Material Selection

We select the optimal POM grade based on your application requirements, considering factors like strength, friction, and chemical exposure.

Precision Manufacturing

Advanced 3D printing equipment produces your POM parts with exceptional accuracy and consistent quality throughout production.

Quality Assurance

Comprehensive inspection using precision measurement tools ensures every component meets your exact specifications before shipment.

Material Properties of POM

High Tensile Strength

POM offers excellent mechanical strength up to 70 MPa, suitable for load-bearing applications.

Low Water Absorption

Minimal moisture uptake ensures dimensional stability in humid environments and underwater applications.

Temperature Resistance

Maintains properties from -40°C to 100°C, suitable for diverse operating conditions.

Excellent Machinability

Post-processing capabilities allow for threading, drilling, and precision finishing operations.

Frequently Asked Questions

What are the advantages of POM 3D printing over traditional methods?

What tolerances can you achieve with POM 3D printing?

Is POM suitable for outdoor applications?

Can you produce POM parts in different colors?

What is the minimum order quantity for POM 3D printing?

How does POM compare to other engineering plastics?

Get Your POM 3D Printing Quote

Contact Rapidaccu today for expert consultation and competitive pricing on your POM 3D printing project.