- Home ›

- 3D Printing ›

- Metal 3D Printing

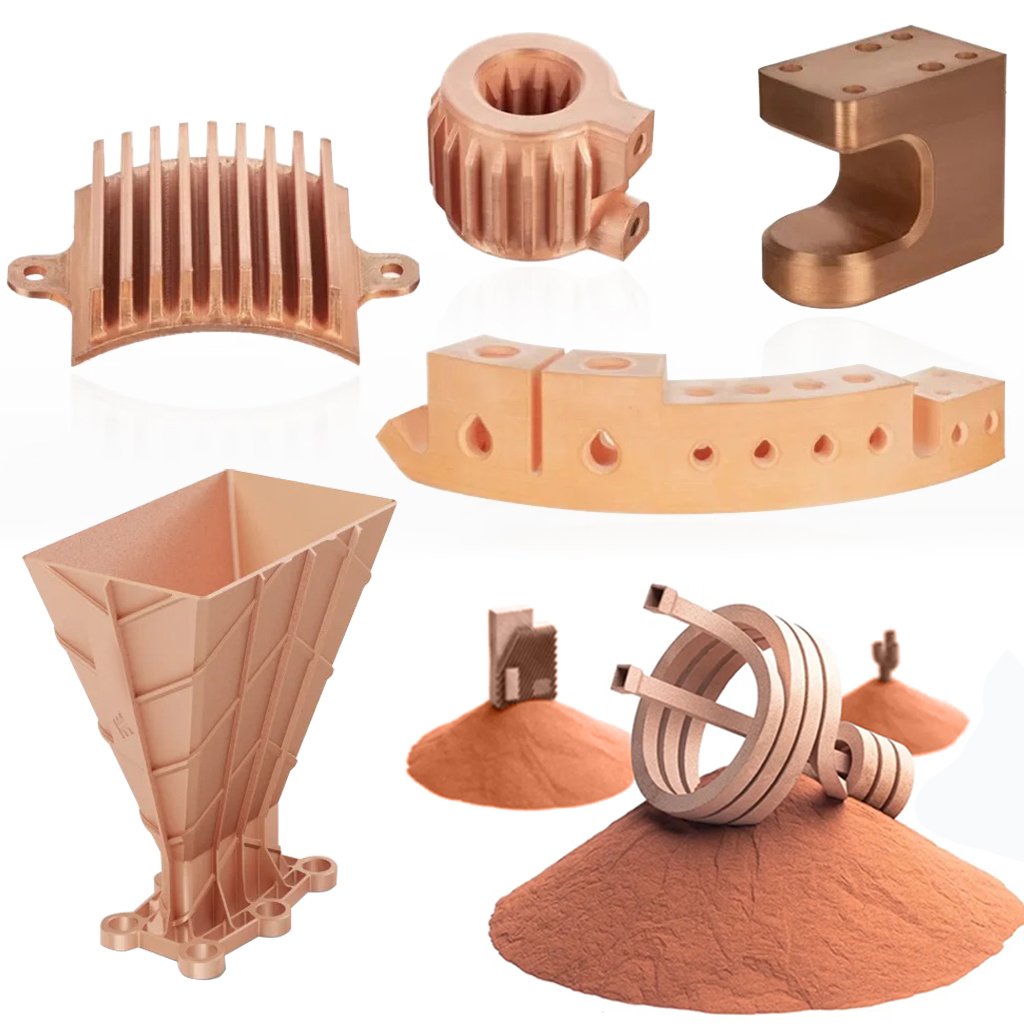

Metal 3D Printing Services

Rapidaccu delivers precision metal additive manufacturing using Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies. From aerospace-grade titanium to corrosion-resistant stainless steel, we produce complex metal parts with exceptional mechanical properties.

What is Metal 3D Printing?

Metal 3D printing, also known as metal additive manufacturing, builds parts layer-by-layer using high-powered lasers to fuse metal powder. This enables the creation of complex geometries, internal channels, and lightweight structures impossible with traditional manufacturing methods.

DMLS Technology

Direct Metal Laser Sintering uses precise laser beams to selectively fuse metal powder particles, creating fully dense parts with mechanical properties comparable to traditionally manufactured components.

Design Freedom

Create complex internal cooling channels, organic lattice structures, and topology-optimized designs that reduce weight while maintaining structural integrity.

No Tooling Required

Eliminate expensive tooling costs and long lead times associated with casting or machining. Ideal for prototypes, low-volume production, and custom parts.

Available Metal Materials

Select from our range of certified metal powders for aerospace, medical, automotive, and industrial applications

Aluminum Alloys

AlSi10Mg, AlSi7Mg – Lightweight with excellent strength-to-weight ratio for aerospace and automotive applications.

Stainless Steel

316L, 304L, 17-4 PH – Corrosion resistant with excellent mechanical properties for medical and industrial use.

Titanium Alloys

Ti-6Al-4V, Grade 2 – Biocompatible, high strength-to-weight for aerospace and medical implants.

Inconel Superalloys

Inconel 625, 718 – Extreme temperature and corrosion resistance for turbines and exhaust systems.

Brass Alloys

C36000, CuZn37 – Excellent machinability and wear resistance for bushings and decorative components.

Copper & Alloys

Pure Copper, CuCrZr – Superior thermal and electrical conductivity for heat exchangers and electronics.

Metal 3D Printing Advantages

Why choose metal additive manufacturing over traditional methods

Lightweight Designs

Topology optimization and lattice structures reduce weight by up to 70% while maintaining strength. Critical for aerospace applications where every gram counts.

Part Consolidation

Combine multiple components into a single printed part, reducing assembly time, eliminating fasteners, and improving reliability.

Rapid Prototyping

Go from CAD to metal part in days instead of weeks. Perfect for design verification, functional testing, and iterative development.

Conformal Cooling

Internal cooling channels follow part geometry for superior heat dissipation in molds, tooling, and thermal management applications.

Low-Volume Production

Economical for quantities from 1 to 1000+ parts without tooling investment. Scale production as demand grows.

Material Efficiency

Unused powder is recycled and reused. Minimal waste compared to subtractive manufacturing which can waste up to 90% of raw material.

Technical Specifications

Industry-leading precision and quality standards

Dimensional Accuracy

- Standard tolerance: ±0.1 mm (±0.004″)

- Layer thickness: 20-50 μm

- Minimum feature size: 0.4 mm

Build Volume

- Maximum part size: 250 × 250 × 325 mm

- Multiple parts per build for efficiency

- Supports nested geometries

Material Certifications

- Aerospace: AS9100, NADCAP

- Medical: ISO 13485, FDA compliant

- Material test reports available

Post-Processing

- Heat treatment (stress relief, HIP)

- CNC machining for critical features

- Surface finishing (polishing, coating)

Applications & Industries

Metal 3D printing serves critical applications across diverse sectors

Aerospace

Turbine blades, fuel nozzles, brackets, lightweight structural components

Medical

Custom implants, surgical instruments, orthopedic devices, dental prosthetics

Automotive

Racing components, custom exhaust, heat exchangers, jigs and fixtures

Industrial

Tooling inserts, conformal cooling molds, wear parts, custom machinery

Energy

Gas turbine components, oil & gas valves, power generation parts

Defense

Weapon components, UAV parts, electronics housings, tactical equipment

Electronics

Heat sinks, RF components, enclosures, thermal management

Research

Academic research, material testing, novel applications, prototyping

Design Guidelines for Metal 3D Printing

Optimize your designs for successful metal additive manufacturing

Design Best Practices

- Minimum wall thickness: 0.4 mm for most metals, 0.6 mm for titanium

- Support structures: Required for overhangs >45°, consider orientation

- Holes and channels: Minimum 1 mm diameter, consider powder removal

- Text and engraving: Minimum height 0.5 mm, depth 0.5 mm

- Clearance gaps: Minimum 0.5 mm between moving parts

Common Design Pitfalls

- Avoid: Large flat surfaces parallel to build plate (causes warping)

- Avoid: Enclosed cavities without powder removal holes

- Avoid: Sharp internal corners (use fillets ≥0.5 mm)

- Avoid: Extremely thin features in unsupported areas

- Avoid: Threads smaller than M3 (post-machine instead)

Need Design Assistance?

Our engineering team provides free Design for Additive Manufacturing (DfAM) consultation to optimize your parts for metal 3D printing. We review your CAD files and suggest improvements for manufacturability, cost reduction, and performance enhancement.

Contact Our EngineersStart Your Metal 3D Printing Project

Get expert guidance on material selection, design optimization, and manufacturing strategy

Our Location

Rongli Industrial Park, Dalang

Longhua District, Shenzhen, China

Get in Touch

info@rapidaccu.comRequest a Quote

Frequently Asked Questions

Common questions about metal 3D printing services