- Home ›

- Pogo pin Manufacturer ›

- Double Ended Pogo Pin

Double Ended Pogo Pin Manufacturing

Dual spring-loaded contact solutions for BGA testing, PCB probing, and floating connection applications. Our double-headed pogo pins deliver exceptional reliability and precision alignment.

Why Double Ended Pogo Pins?

Unique dual-contact design provides versatility for complex testing and connection scenarios

Floating Design

Accommodates height variations and misalignment tolerances

Dual Contact

Spring-loaded contacts on both ends for reliable connections

Test Applications

Ideal for BGA testing fixtures and ICT test probes

Reversible

Can be used in either orientation for flexibility

Technical Excellence

Height Range: 8mm – 25mm

Available in various heights to suit different fixture requirements

Diameter: 0.68mm – 3.0mm

Multiple diameter options for different pitch requirements

Travel: 1.0mm – 3.0mm

Generous spring travel for reliable contact under varying conditions

Current: Up to 5A

High current capacity for power and signal applications

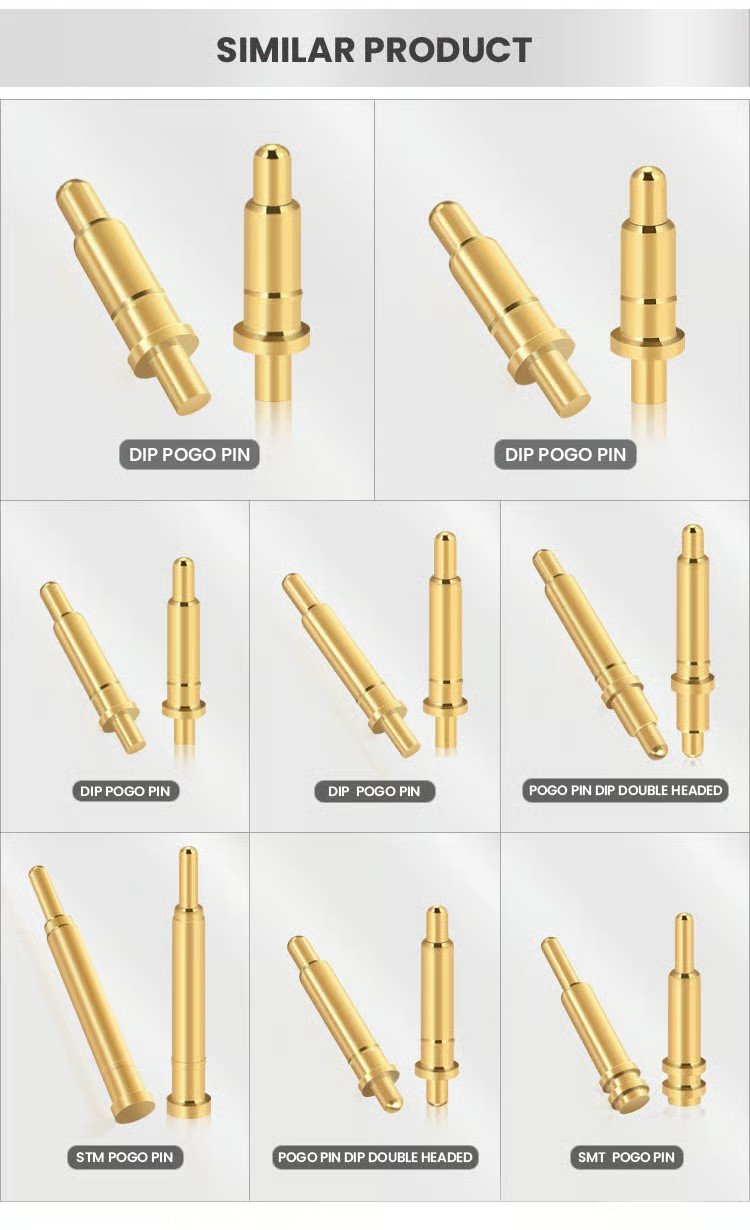

Double Ended Pogo Pin Product Line

Precision-engineered for demanding test and connection applications

Standard Double-Ended Probes

Dual spring-loaded contacts for keyboard and device testing

High Current Series

22mm height models capable of handling high current loads

Precision Micro Probes

Fine-pitch double-ended pins for high-density applications

Rapidaccu Manufacturing Excellence

As a trusted CNC machining manufacturer based in Shenzhen, China, we combine advanced manufacturing technology with rigorous quality control to deliver double ended pogo pins that exceed industry standards.

15+ Years Expertise

Specialized knowledge in pogo pin and connector manufacturing

ISO Certified Quality

ISO 9001, ISO 14001, ISO 45001, and IECQ QC080000

Exceptional Support

Dedicated customer service and transparent transactions

Key Applications

Where double ended pogo pins make a difference

BGA Testing

ICT Fixtures

Keyboard Probing

Functional Testing

Floating Connectors

Frequently Asked Questions

What makes double ended pogo pins different from standard pins?

What is the typical lifespan of double ended pogo pins?

Can you customize double ended pogo pins for specific test fixtures?

What materials are recommended for high-frequency applications?

Request Your Custom Quote

Expert double ended pogo pin manufacturing for your application

Contact Rapidaccu

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comManufacturing Experience

Over 15 Years in Precision Pogo Pin Manufacturing