- Home ›

- Pogo pin Manufacturer ›

- Thread Screw Pogo Pin

Thread Screw Pogo Pin Solutions

Secure threaded mounting spring-loaded connectors engineered for high-vibration environments and demanding applications. Our screw-type pogo pins provide superior mechanical retention with exceptional electrical performance.

Get Your Quote

Thread Screw Mounting Advantages

Secure Fastening

Threaded design provides robust mechanical retention and prevents loosening

Vibration Resistant

Ideal for automotive, aerospace, and industrial applications with high vibration

Adjustable Height

Thread depth can be adjusted for precise contact pressure control

Easy Installation

Standard thread sizes simplify assembly and replacement procedures

High Current

Support power applications up to 12A with proper heat management

Serviceable

Threaded design allows easy removal and replacement without PCB damage

Technical Specifications

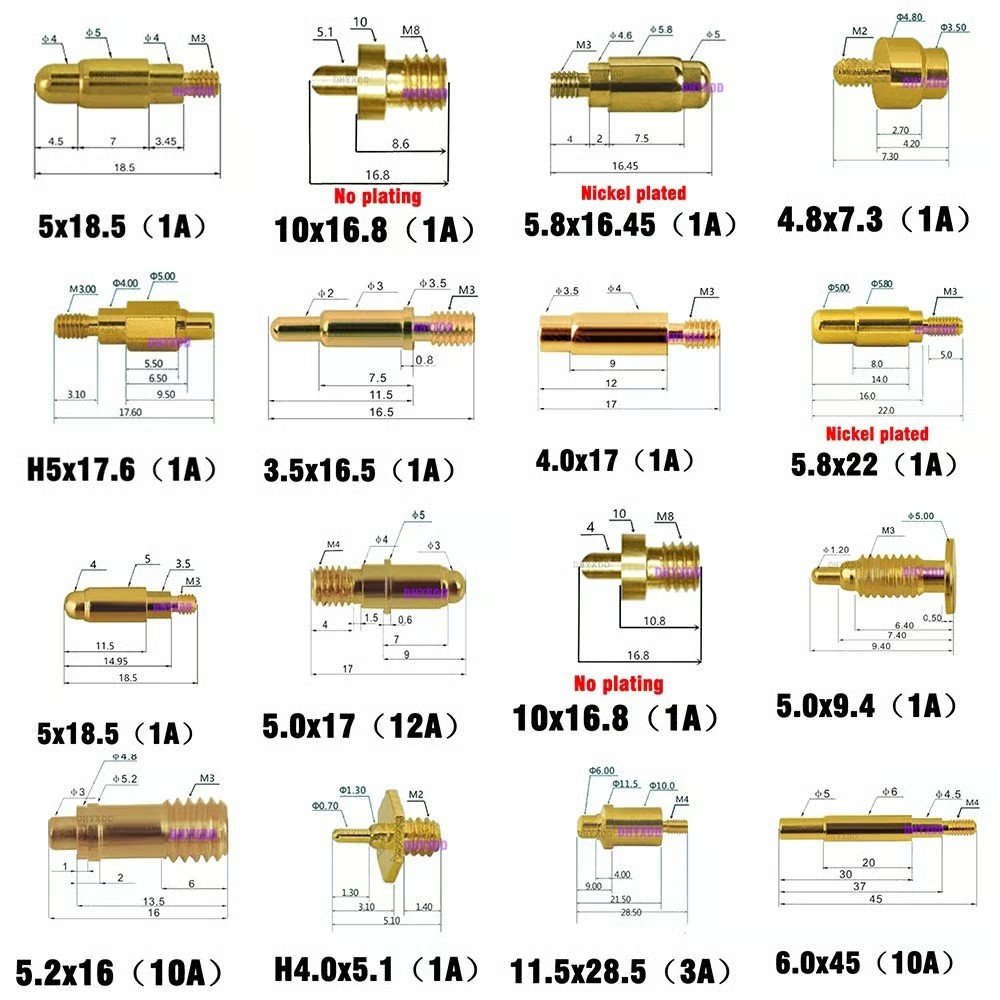

Thread Types

M2, M3, M4, M5, M6 metric threads and custom options

Overall Length

10mm to 40mm depending on application requirements

Spring Travel

1.5mm to 4.0mm compression range for reliable contact

Current Capacity

1A to 12A depending on pin diameter and contact design

Material Options

Brass, stainless steel, with gold or nickel plating

Thread Screw Pogo Pin Products

Professional threaded connector solutions

High-Current Thread Models

Durable solutions for power applications

Custom Thread Designs

Wholesale manufacturer with custom options

Magnetic Circular Socket

Male and female DC power connectors

M4 Thread Brass Series

12A current ratio spring loaded contacts

Test Probe Models

Electrical contact pins for testing applications

Screw-in Thread Types

Wholesale direct from China manufacturer

About Rapidaccu

Based in Shenzhen, China, Rapidaccu is a trusted CNC machining manufacturer specializing in precision pogo pins and connectors. Our expertise in thread screw pogo pin manufacturing ensures products that meet the most stringent quality and performance requirements.

15+ Years

Industry Experience

4 ISO

Quality Certifications

Application Sectors

Automotive

Dashboard panels and control units

Aerospace

Avionics and navigation systems

Industrial

Heavy machinery connections

Defense

Military equipment interfaces

Marine

Navigation and control systems

Telecom

Base stations and infrastructure

Test Fixtures

Automated testing equipment

Power Systems

High-current distribution panels

Frequently Asked Questions

What thread standards do you support for screw pogo pins?

How much torque should be applied when installing thread screw pogo pins?

Can thread screw pogo pins be used in high-vibration environments?

What materials are best for thread screw pogo pins in outdoor applications?

Request Your Thread Screw Pogo Pin Quote

Secure threaded solutions for demanding applications

Contact Information

Manufacturing Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

Over 15 Years in Pogo Pin and Connector Manufacturing