- Home ›

- Pogo pin Manufacturer ›

- Solder Cup Pogo Pin Connector

Solder Cup Pogo Pin Connector

Reliable wire termination solution with precision-machined solder cups. Designed for permanent wire connections in test fixtures, charging stations, and industrial equipment.

Wire Termination

100% Secure

Spring Force

50-200gf

What is Solder Cup Termination?

Solder cup pogo pins feature a hollow cup at the rear end, allowing wires to be soldered directly into the connector for permanent, high-reliability connections

Permanent Connection

Soldered wires create robust mechanical and electrical bonds

Easy Assembly

Simple soldering process for quick production assembly

High Reliability

Excellent vibration and shock resistance for industrial use

Low Resistance

Minimal contact resistance ensures optimal current flow

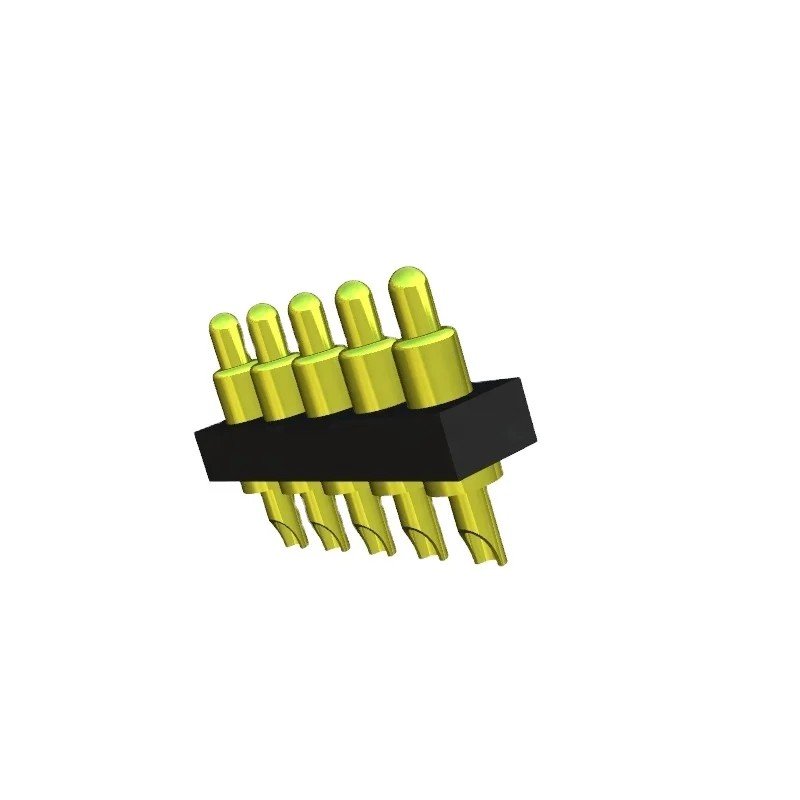

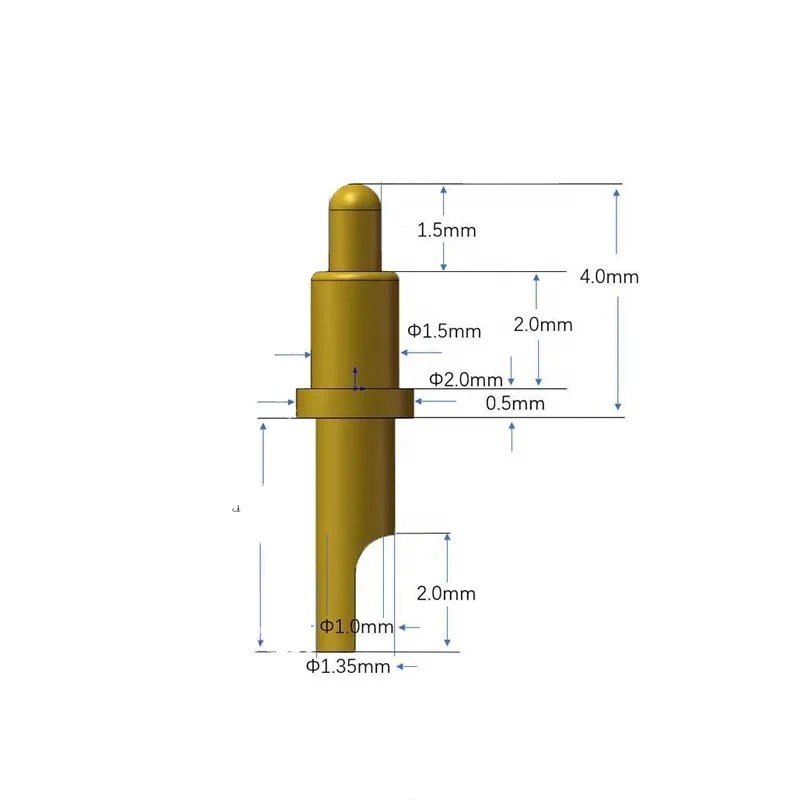

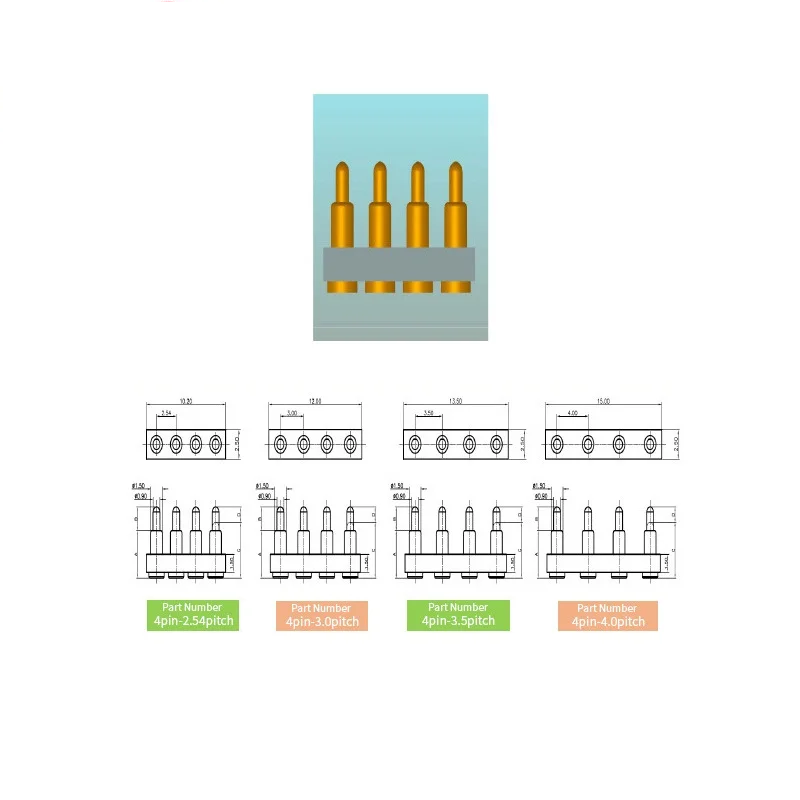

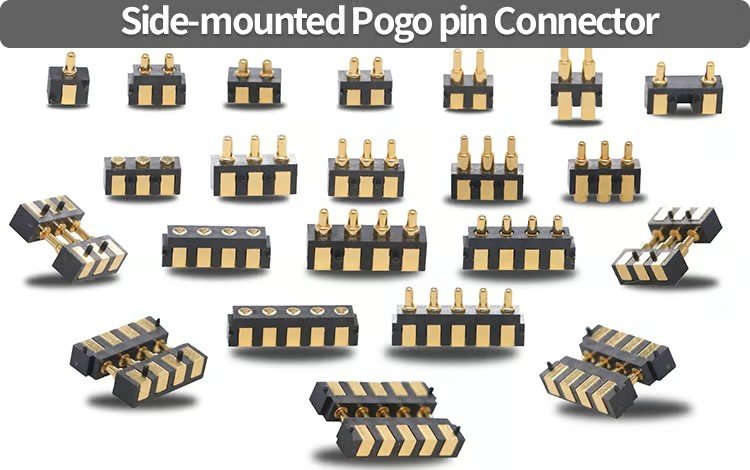

Product Gallery

5 Pin 2mm Pitch Solder Cup

4mm High Current Connector

Magnetic Spring Male Pin

Custom Bending Double Head

Spring Loaded Pin Soldercup

Customized Spring Pin Connector

Through Hole Sleeve Plunger

4Pin Enhanced Connectivity

Technical Advantages

Superior Solder Joint Quality

Deep solder cups ensure complete wire coverage and strong mechanical bonds that withstand thermal cycling and vibration

Consistent Spring Performance

Precision-wound springs maintain optimal contact force throughout the connector’s lifetime, ensuring reliable electrical contact

Multiple Plating Options

Available with gold, nickel, or tin plating to match your specific environmental and electrical requirements

Application Scenarios

Test Fixtures

Permanent wiring solutions for ICT and functional test fixtures, providing stable connections for high-volume production testing environments

Charging Stations

Robust wire connections for battery charging docks, power banks, and charging cradles requiring repeated insertions and high reliability

Industrial Equipment

Heavy-duty applications in automation systems, robotic end effectors, and industrial control panels where vibration resistance is critical

Why Choose Rapidaccu

As a leading CNC machining manufacturer, we bring precision and quality to every solder cup pogo pin connector we produce.

Over 15 Years of Expertise in Pogo Pin and Connector Manufacturing

Certified Quality: ISO 9001, ISO 14001, ISO 45001, and IECQ QC080000

Exceptional Customer Support and Transparent Transactions

Frequently Asked Questions

What wire gauges are compatible with solder cup pogo pins?

How does solder cup termination compare to crimp termination?

What current ratings are available?

Can you customize the cup depth and diameter?

What is the recommended soldering temperature?

Do you offer samples for testing?

Get in Touch

Ready to discuss your solder cup pogo pin connector needs? Our engineering team is here to help you design the perfect solution.

Factory Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Business Hours

Monday – Friday: 9:00 AM – 6:00 PM (CST)