- Home ›

- Pogo pin Manufacturer ›

- Bending Type Pogo Pin Connector

Bending Type Pogo Pin Connector

Flexible bending designs for complex PCB configurations. Custom angles from 30° to 180° to perfectly match your application needs.

Bending Angle Options

Our bending type pogo pin connectors can be customized to any angle between 30° and 180° to accommodate your unique PCB layout challenges

Angled Design

Ideal for compact spaces with moderate directional changes

Right Angle

Perfect for horizontal PCB connections and side mounting

Obtuse Bend

Specialized applications requiring wider angle connections

Any Angle

Tailored to your exact specifications from 30° to 180°

Product Portfolio

Explore our diverse range of bending type pogo pin connectors

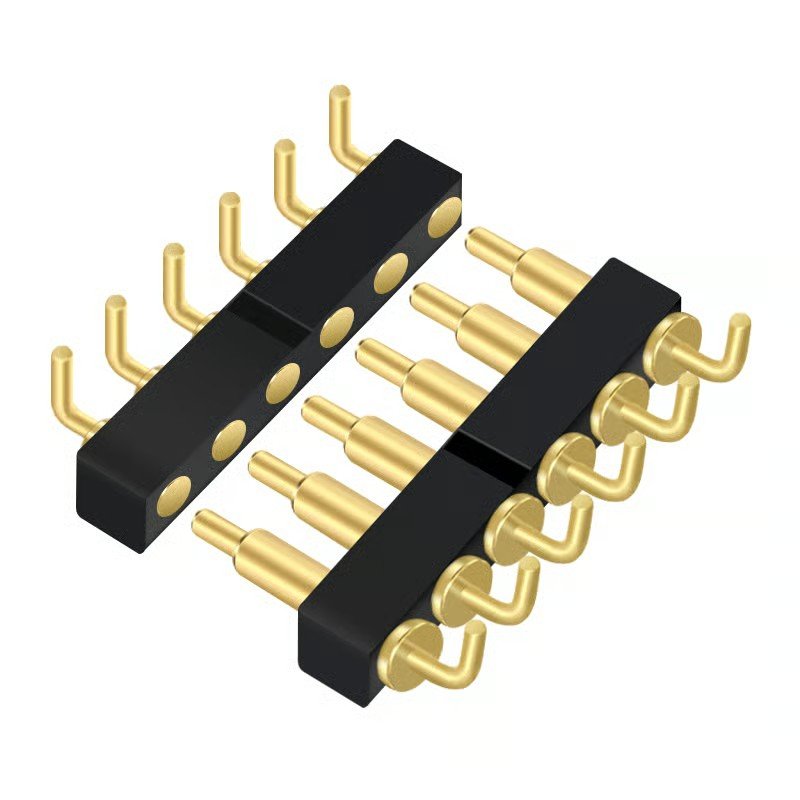

Veneer Plugboard Bending Type

Gold aluminum low high current pogopin

90 Degree Bend Design

Precision and durability combined

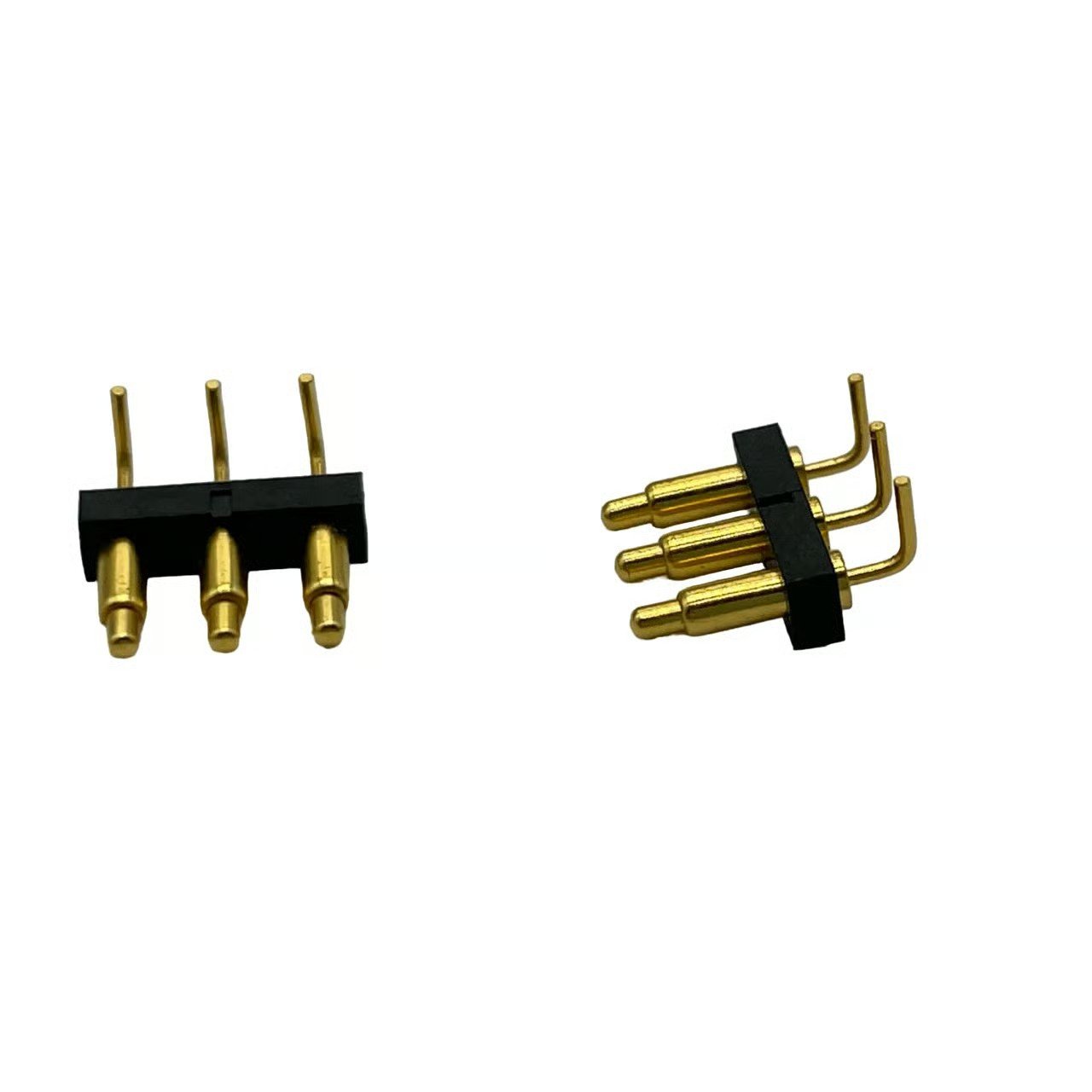

Brass C3604 Bending Pins

3.0mm pitch spring connectors

3A Current Bending Pins

80gf spring force brass material

Custom Bending Contact

SMT DIP solder cup double head type

2.54mm Pitch Gold Plated

90 degree bend PCB connector

Design Flexibility Meets Precision

Our bending type pogo pin connectors combine the flexibility of custom angles with the precision of CNC manufacturing, delivering optimal solutions for complex PCB layouts.

Custom Angle Manufacturing

Advanced CNC machining allows us to create precise bends at any angle from 30° to 180°, perfectly matching your design requirements

Consistent Quality

Every bend is manufactured with tight tolerances (±2°) ensuring consistent electrical and mechanical performance across production runs

Application Versatility

Suitable for diverse applications including wearables, IoT devices, medical equipment, automotive electronics, and industrial automation

Key Advantages

Angle Flexibility

Any angle from 30° to 180° to match your exact PCB geometry

Space Saving

Optimized for compact designs with limited vertical or horizontal space

High Precision

±2° angle tolerance ensures consistent performance and easy assembly

Durability

Robust construction maintains spring force and contact quality over 100K+ cycles

Rapidaccu Excellence

As a leading manufacturer with over 15 years of experience, Rapidaccu delivers bending type pogo pin connectors that exceed industry standards.

Over 15 Years of Expertise in Pogo Pin and Connector Manufacturing

Certified Quality: ISO 9001, ISO 14001, ISO 45001, and IECQ QC080000

Exceptional Customer Support and Transparent Transactions

Frequently Asked Questions

Everything you need to know about bending type pogo pin connectors

Q What bending angles can you manufacture?

Q How do bending pins differ from straight pins?

Q Does bending affect electrical performance?

Q What applications benefit most from bending pins?

Q Can you provide prototypes for testing?

Q What materials and plating are available?

Let’s Create Your Custom Solution

Our engineering team is ready to develop the perfect bending type pogo pin connector for your unique application. Share your requirements and let’s get started.

Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Hours

Monday – Friday: 9:00 AM – 6:00 PM (CST)

Request Custom Quote

Tell us about your project requirements and our team will provide a detailed quote within 24 hours.