- Home ›

- Pogo pin Manufacturer ›

- Magnetic Connector

Premium Magnetic Connector Manufacturing

Rapidaccu specializes in precision magnetic connectors with advanced pogo pin technology. Our ISO-certified manufacturing ensures reliable power and data transmission for demanding applications worldwide.

Request Custom QuoteMagnetic Connector Product Range

Engineered for precision, built for reliability

Waterproof 4 Pin Magnetic Connector

DC power connection with IP67 protection

3 Pin Pogo Magnetic Connector

2A current capacity, 2.54mm pitch design

High Current 3A Magnetic Connector

USB charging cable with strong magnetic force

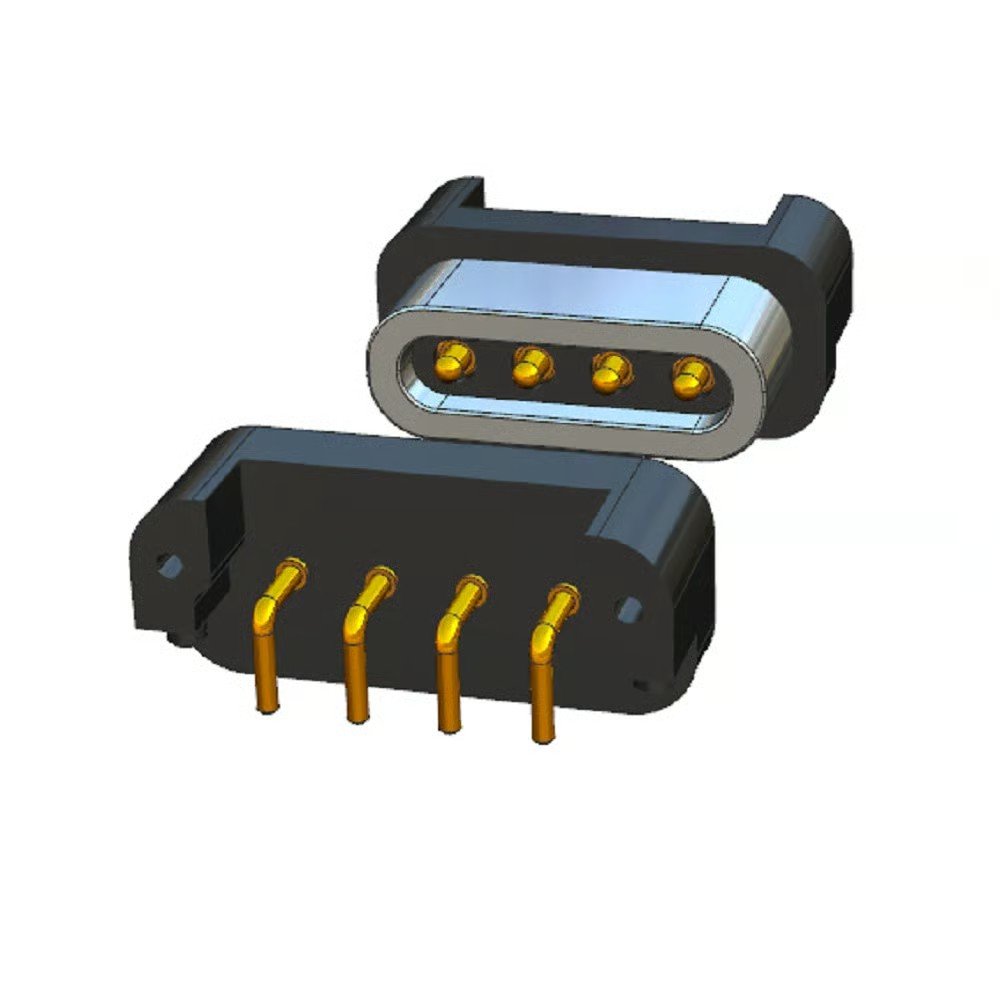

Multi-Pin Magnetic Connector

2-5 pin options for power charging and data

Right Angle 4Pin Magnetic Connector

Space-saving design for compact devices

Advanced Manufacturing Capabilities

Precision CNC Machining

State-of-the-art equipment ensures dimensional accuracy within ±0.01mm tolerance for critical components

Custom Design Solutions

Engineering team works with your specifications to develop magnetic connectors for unique applications

Quality Testing Protocols

Comprehensive testing including contact resistance, insertion force, and magnetic strength verification

Technical Specifications

Current Rating

2A – 5A

Depending on pin configuration

Contact Resistance

≤50mΩ

Low resistance for efficient power transfer

Mating Cycles

10,000+

Extended durability for frequent use

Industry Applications

Consumer Electronics

Smartphones, tablets, wearables requiring quick-connect charging solutions

Medical Devices

Sterilizable connectors for diagnostic and monitoring equipment

Industrial Automation

Robust connectors for harsh manufacturing environments

Automotive Systems

Reliable connections for vehicle electronics and charging systems

Why Choose Rapidaccu?

15 Years Manufacturing Expertise

Proven track record in magnetic connector production

ISO 9001, ISO 14001, ISO 45001 Certified

International quality and environmental standards

IECQ QC080000 Compliance

Hazardous substance process management certification

Global Export Experience

Reliable international shipping and transparent communication

Our Manufacturing Process

From concept to delivery

Design Review

Technical specifications analysis

Material Selection

High-grade metals and magnets

Precision Machining

CNC manufacturing to exact tolerances

Quality Testing

Comprehensive performance verification

Export Packaging

Secure packaging for global delivery

Frequently Asked Questions

What are the advantages of magnetic connectors over traditional connectors?

Can you customize magnetic connectors for specific applications?

What is the minimum order quantity for custom magnetic connectors?

Are your magnetic connectors waterproof?

What materials are used in your magnetic connectors?

How do you ensure quality control in manufacturing?

Get Your Custom Quote Today

Contact Information

Factory Address

Rongli Industrial Park, Dalang, Longhua District

Shenzhen, China

Business Hours

Monday – Friday: 8:00 AM – 6:00 PM (CST)

Saturday: 9:00 AM – 5:00 PM (CST)

Why Partner With Us?

- ISO Certified Quality Systems

- 15+ Years Industry Experience

- Competitive Pricing

- Transparent Communication