- Home ›

- Pogo pin Manufacturer ›

- Pogo Pin Connector

Pogo Pin Connector Manufacturing

Professional spring-loaded pogo pin connectors engineered for reliable electrical connections. Our precision-manufactured connectors deliver consistent performance across diverse applications and demanding environments.

Get QuotePogo Pin Connector Solutions

Advanced spring-loaded technology for modern electronics

Reliable Contact

Consistent electrical connection with spring force

High Durability

10,000+ mating cycles guaranteed

Space Efficient

Compact design for tight spaces

Customizable

Tailored solutions for your needs

Product Specifications

Pitch Options

2.0mm, 2.5mm, 2.54mm standard pitches available

Pin Count

2 to 12 positions, single and dual row configurations

Current Rating

1A to 3A per pin depending on design

Temperature Range

-40°C to +85°C operating temperature

Pogo Pin Connector Product Range

Magnetic 3-Pin Connectors

2A 36V male and female spring power charge connectors

Through Hole Models

2.0mm OD battery spring loaded PCB needle connectors

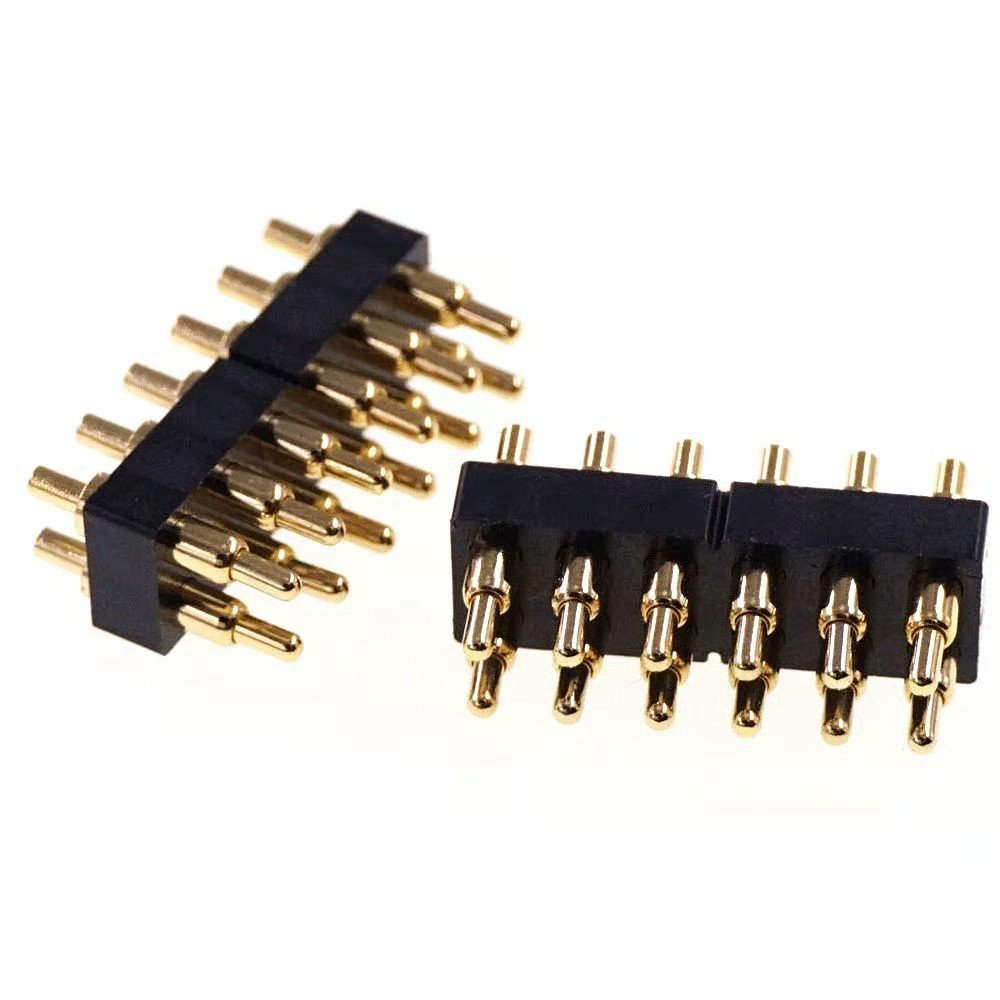

Multi-Pin Series

High quality 2, 3, 4, 6 pins spring loaded accessories

3.0mm Pitch Brass

C3604 bending spring pins 1x03P configuration

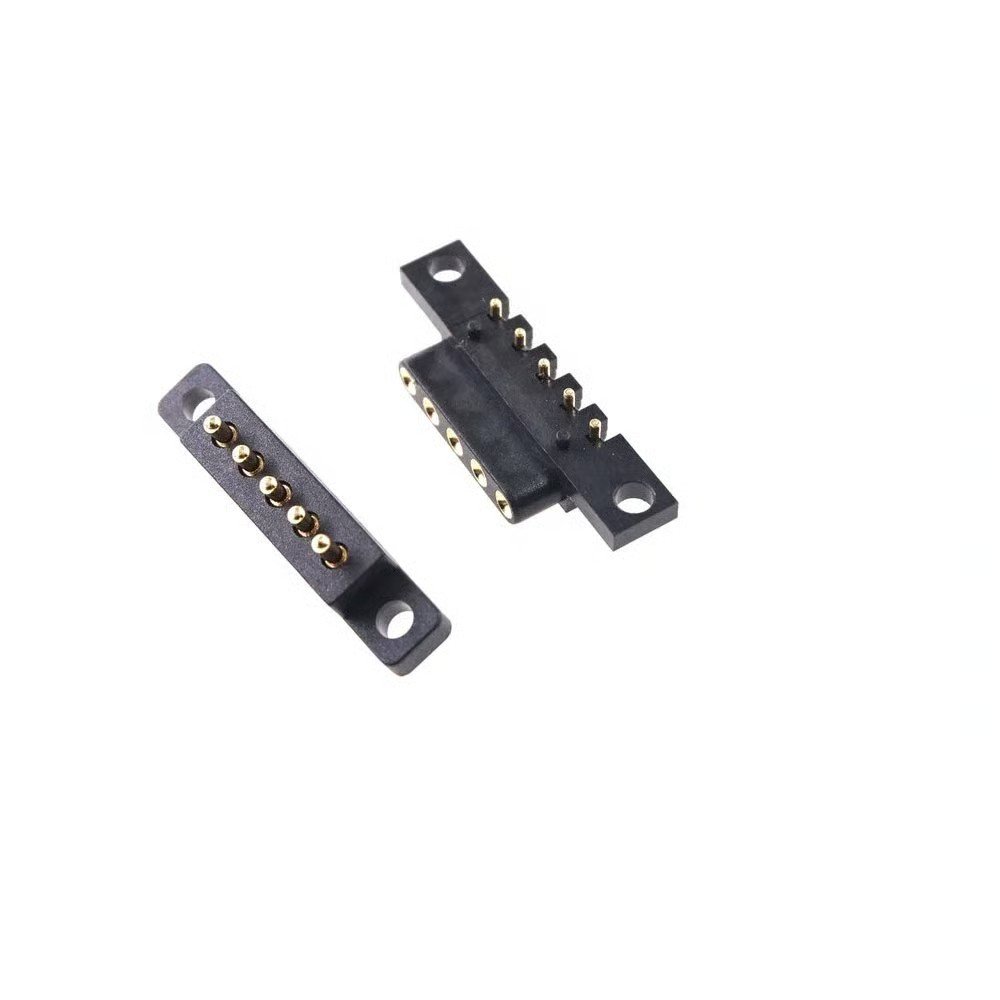

12-Position Arrays

2.54mm pitch 2×6 mounting holes magnetic connectors

Right Angle SMT

2.5mm grid horizontal surface mount headers

Rapidaccu Manufacturing Excellence

Based in Shenzhen, China, Rapidaccu is a trusted CNC machining manufacturer specializing in precision pogo pin connectors. With over 15 years of expertise, we deliver quality products that meet international standards and exceed customer expectations.

Over 15 Years of Expertise

Specialized in pogo pin and connector manufacturing

Certified Quality

ISO 9001, ISO 14001, ISO 45001, and IECQ QC080000

Exceptional Customer Support

Transparent transactions and dedicated service team

Industry Applications

Trusted across multiple sectors

Consumer Electronics

Smartphones, tablets, wearables

Medical Devices

Diagnostic and therapeutic equipment

Automotive

Dashboard and control systems

Industrial

Automation and control equipment

Charging Systems

Power delivery and docking stations

Test Equipment

ICT and functional test fixtures

Telecommunications

Network and communication devices

Computing

Laptops and peripheral accessories

Frequently Asked Questions

What is a pogo pin connector?

How long do pogo pin connectors last?

Can pogo pin connectors be customized?

What materials are used in pogo pin connectors?

Request Your Pogo Pin Connector Quote

Professional manufacturing with certified quality

Contact Information

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comExperience

Over 15 Years in Pogo Pin and Connector Manufacturing