- Home ›

- Pogo pin Manufacturer ›

- SMT/SMD Pogo Pin Connector

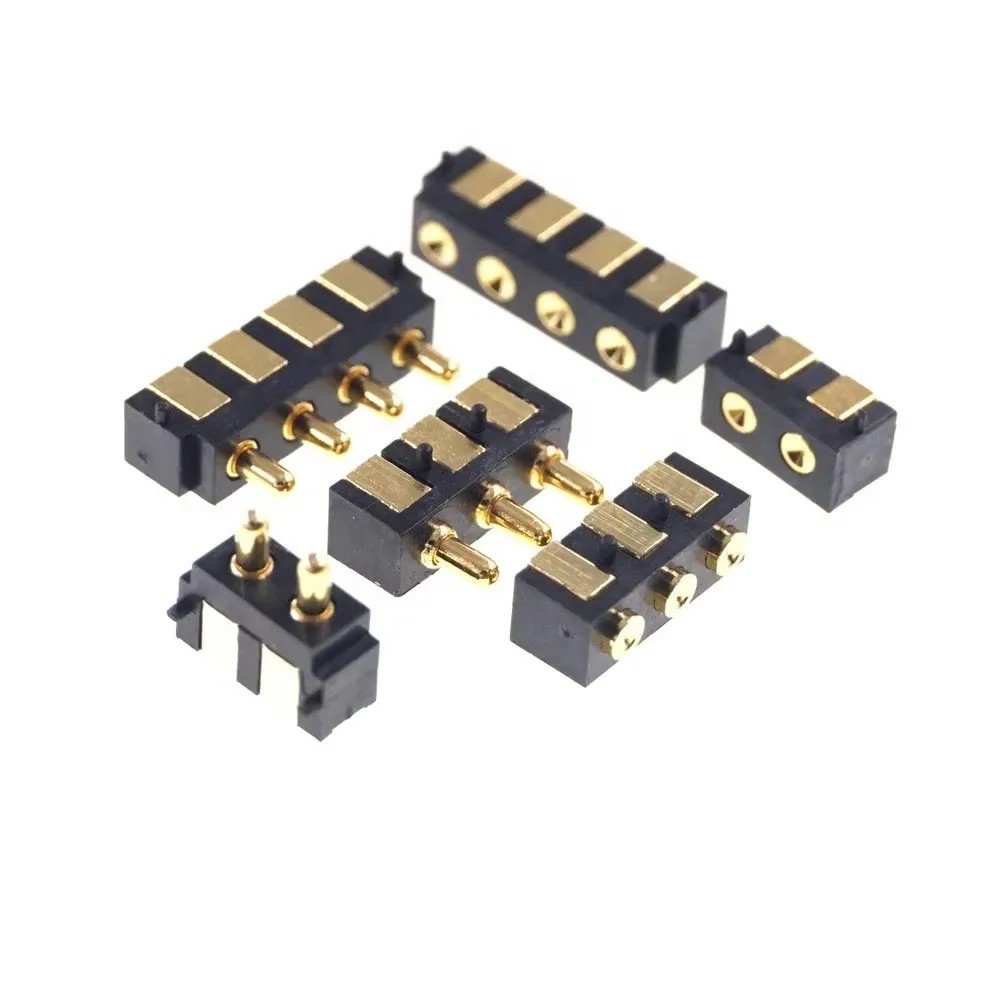

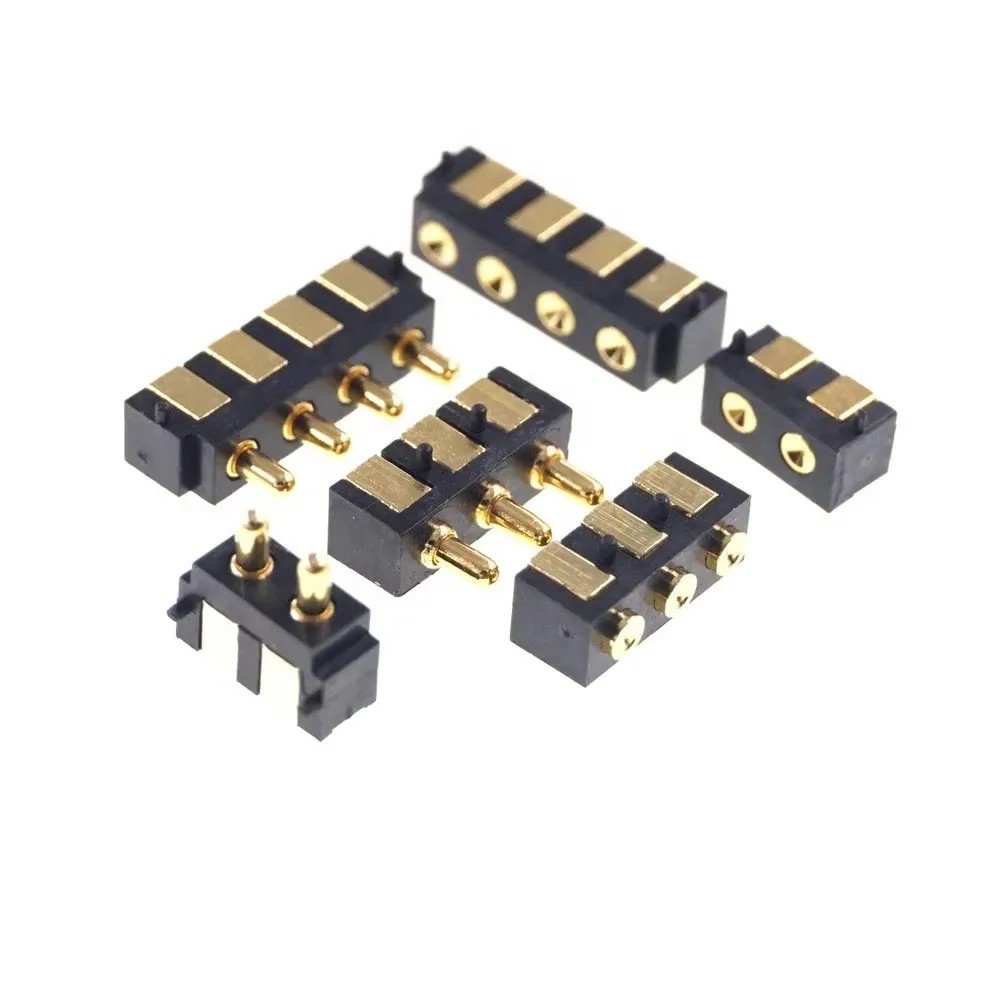

SMT/SMD Pogo Pin Connector Manufacturing

Precision surface mount pogo pin connectors designed for automated PCB assembly. Our SMT/SMD solutions deliver reliable electrical contact in compact spaces with exceptional performance.

SMT/SMD Connector Advantages

Optimized for modern automated assembly processes

Pick & Place Compatible

Designed for automated surface mount technology assembly equipment

Space Saving

Minimal PCB footprint for high-density circuit board designs

High Reliability

Consistent spring force and electrical performance over 10,000 cycles

Reflow Capable

Withstands standard reflow soldering temperatures without damage

Low Profile

Ultra-compact height for slim device designs and applications

High Current

Support signal and power applications up to 3A per pin

Technical Features

Pitch Range: 2.0mm to 5.0mm

Standard and custom pitch options available

Pin Configuration: 2 to 6 positions

Single row and right angle designs

Height: 3.5mm to 7.5mm

Multiple heights for different clearance requirements

Operating Temperature: -40°C to +85°C

Extended temperature ranges available

SMT/SMD Pogo Pin Connector Products

Comprehensive surface mount solutions

5-Pin Vertical SMT

Female and male type for charger applications

Spring Loaded Type

Surface mount power charge connectors

Multi-Pin SMD Arrays

High-density surface mount connectors

Test Pin SMT

Custom spring loaded for testing applications

Multi-Pin Spring Contact

SMT/SMD reliable performance connectors

Right Angle SMT Headers

2.5mm pitch horizontal target pad connectors

Why Choose Rapidaccu

As a leading CNC machining manufacturer in Shenzhen, we specialize in precision SMT/SMD pogo pin connectors. Our commitment to quality and innovation ensures your products perform reliably in demanding applications.

Over 15 Years of Expertise

Specialized in pogo pin and connector manufacturing

Certified Quality

ISO 9001, ISO 14001, ISO 45001, and IECQ QC080000

Exceptional Customer Support

Transparent transactions and dedicated technical assistance

Application Industries

Mobile Devices

Wearable Tech

Medical Devices

Charging Docks

Audio Products

Cameras

Gaming

Test Equipment

Frequently Asked Questions

What is the difference between SMT and through-hole pogo pin connectors?

Can SMT pogo pin connectors handle reflow soldering?

What PCB pad design is recommended for SMT pogo pins?

What is the typical current rating for SMT pogo pin connectors?

Request Your SMT/SMD Pogo Pin Connector Quote

Professional surface mount solutions

Contact Information

Factory Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

Over 15 Years in Pogo Pin and Connector Manufacturing