- Home ›

- Pogo pin Manufacturer ›

- Solder Cup Pogo Pin

Solder Cup Pogo Pin Manufacturing

Premium spring-loaded pogo pins with integrated solder cup terminals for wire connection applications. Our solder cup design enables flexible assembly configurations while maintaining exceptional electrical reliability.

Solder Cup Design Benefits

Wire-to-board connectivity with spring-loaded reliability

Wire Connection

Easy wire soldering to solder cup terminal

Flexible Assembly

Adapt to various mounting configurations

Strain Relief

Secure wire attachment reduces stress

High Current

Support power transmission applications

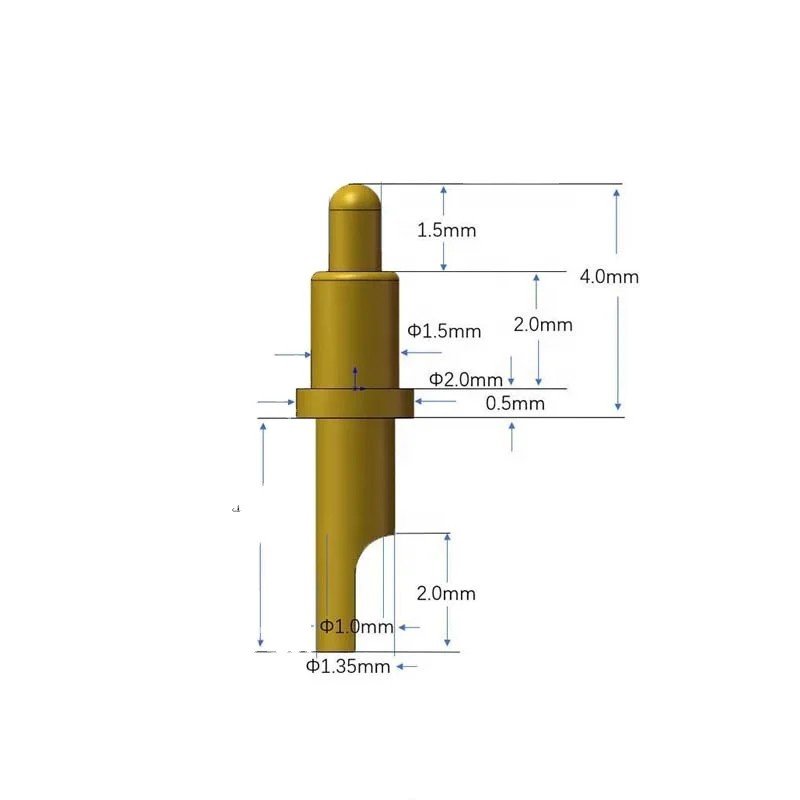

Product Specifications

Pitch Options

2.0mm, 2.54mm, 4.0mm standard pitches available

Pin Count

Single pin to 12-pin arrays and custom configurations

Solder Cup Material

Brass construction with nickel or gold plating

Spring Travel

1.0mm to 3.0mm compression stroke

Current Rating

1A to 5A depending on pin diameter and design

Solder Cup Pogo Pin Product Line

Comprehensive wire connection solutions

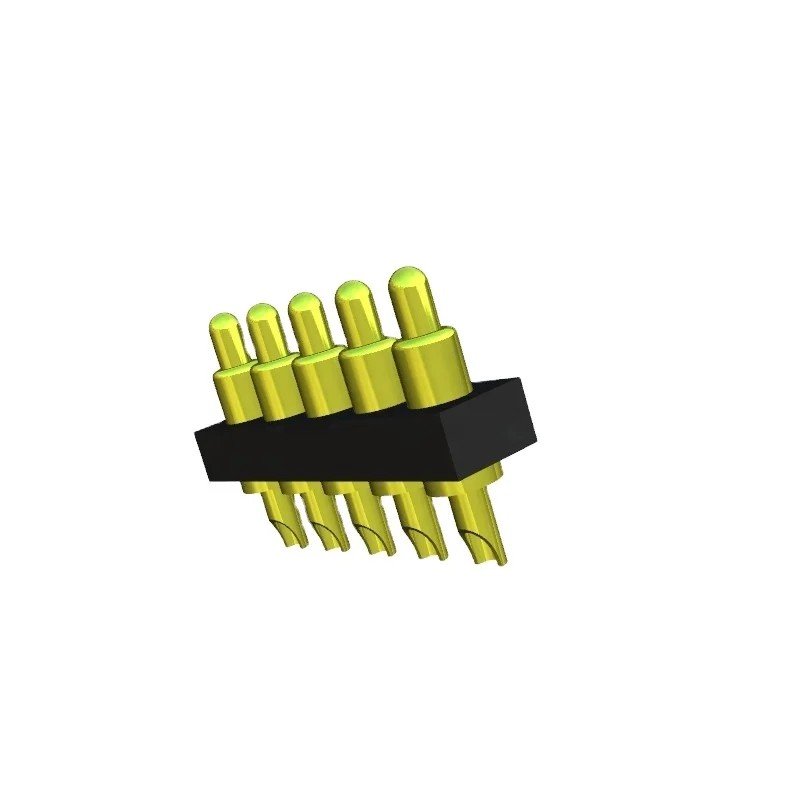

Magnetic Connector Series

4mm solder cup with high current capacity for PCB applications

High Current

Through Hole Models

Spring loaded pin with soldercup contact sleeve plunger design

PCB Mount

Custom High-Current Types

SMT, DIP, solder cup, bending, and double head configurations

Customizable

Custom Pitch Arrays

1.27mm, 2.0mm, 2.5mm pitch solder cup connectors

Manufacturing Excellence

Rapidaccu specializes in precision CNC machining for solder cup pogo pins. Located in Shenzhen, China, our state-of-the-art facility combines advanced manufacturing technology with rigorous quality control processes to deliver products that exceed international standards.

Precision Machining

Advanced CNC equipment ensures dimensional accuracy and consistency

Quality Testing

100% inspection for contact resistance, spring force, and durability

Material Selection

Premium brass and copper alloys for optimal performance

Surface Finishing

Gold, nickel, or tin plating options for various applications

Quality Certifications

Over 15 Years Experience

Specialized expertise in pogo pin and connector manufacturing with exceptional customer support and transparent transactions.

Key Applications

Industries relying on solder cup pogo pins

Industrial Equipment

Sensor connections and control panel interfaces

Medical Devices

Diagnostic equipment wire harness connections

Automotive Systems

Dashboard displays and power distribution

Power Supplies

High-current charging and power delivery systems

Testing Equipment

Custom test fixtures with wire connections

Communications

Network equipment and antenna systems

Frequently Asked Questions

What wire gauge is suitable for solder cup pogo pins?

How do solder cup pogo pins compare to PCB-mount versions?

What soldering temperature can solder cup pogo pins withstand?

Can solder cup pogo pins be used in outdoor or harsh environments?

Request Your Solder Cup Pogo Pin Quote

Expert wire connection solutions for your application

Contact Rapidaccu

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comIndustry Experience

Over 15 Years in Pogo Pin and Connector Manufacturing