- Home ›

- Pogo pin Manufacturer ›

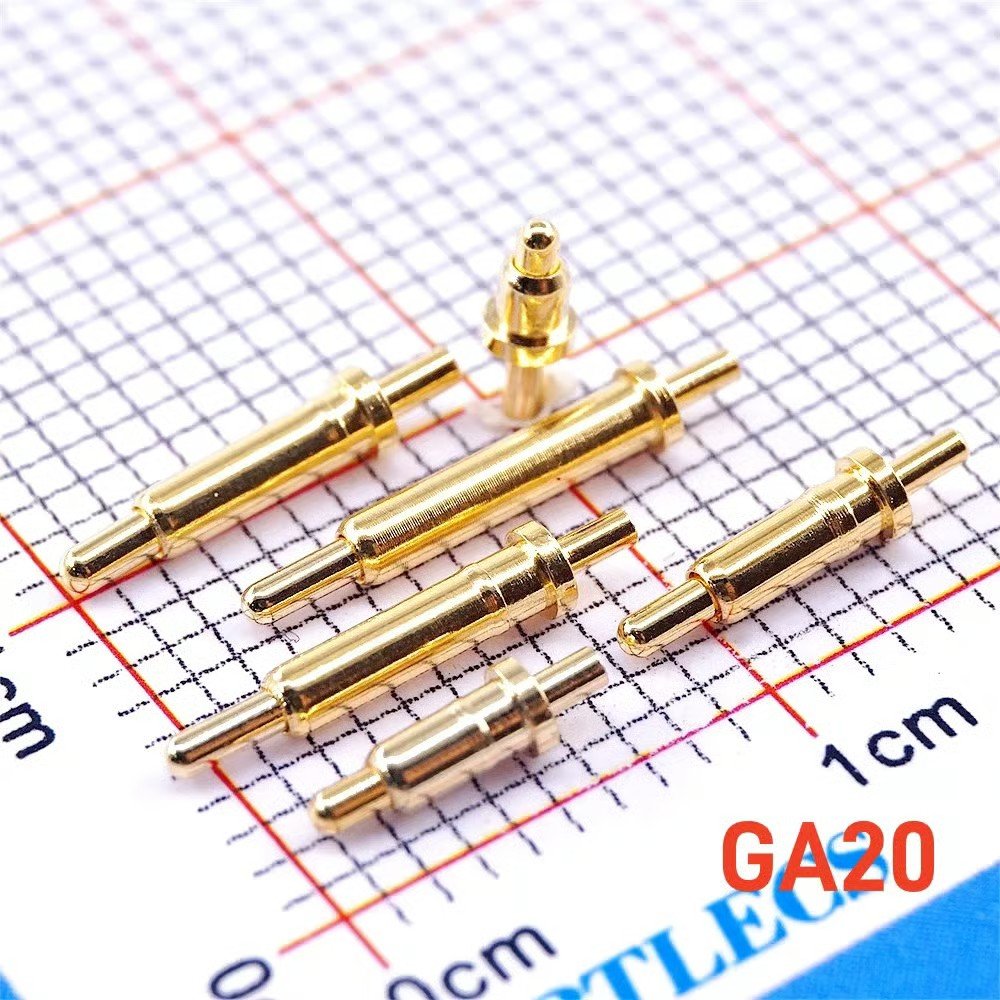

- Through Hole Pogo Pin

Through Hole Pogo Pin Solutions

Robust through-hole mount pogo pins engineered for high-reliability applications. Our DIP connectors provide superior mechanical strength and excellent electrical performance for demanding environments.

Get Quote Now

Through Hole Pogo Pin Capabilities

Professional manufacturing with precision CNC machining

High Durability

Withstands 10,000+ mating cycles

Strong Connection

Superior mechanical retention

High Current

Up to 8A current capacity

Custom Heights

13mm to 20.5mm available

Product Features

Versatile Mounting Options

Compatible with standard PCB through-hole assembly processes including wave soldering and selective soldering.

Premium Materials

Manufactured from brass C3604 with beryllium copper springs, ensuring long-term reliability and consistent performance.

Wide Temperature Range

Operates reliably from -40°C to +125°C, suitable for industrial and automotive applications.

Multiple Plating Finishes

Available in gold, nickel, or tin plating to meet specific conductivity and corrosion resistance requirements.

Through Hole Pogo Pin Product Range

Standard DIP Connectors

Straight through-hole mount with flange design

Battery Contacts

High-current through-hole spring probes

Heavy-Duty Models

Industrial-grade through-hole connectors

Gold-Plated Series

Premium through-hole with gold finish

2-Pin Solutions

Compact through-hole male and female contacts

High-Precision OEM

Custom through-hole spring pins

About Rapidaccu

As a leading CNC machining manufacturer in China, Rapidaccu has been dedicated to producing high-quality pogo pins and connectors for over 15 years. Our commitment to precision, quality, and customer satisfaction has made us a trusted partner for businesses worldwide.

Industries We Serve

Our through hole pogo pins are trusted across multiple sectors

Industrial Automation

Automotive

Aerospace

Telecommunications

Laboratory Equipment

Test & Measurement

Common Questions

What hole diameter is required for through hole pogo pins?

Are through hole pogo pins suitable for high-vibration environments?

Can through hole pogo pins be used with wave soldering?

What is the typical lead time for custom through hole pogo pins?

Request Your Through Hole Pogo Pin Quote

Expert manufacturing with ISO certified quality assurance

Get In Touch

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comQuality Certifications

ISO 9001, ISO 14001, ISO 45001, IECQ QC080000