- Home ›

- Pogo pin Manufacturer ›

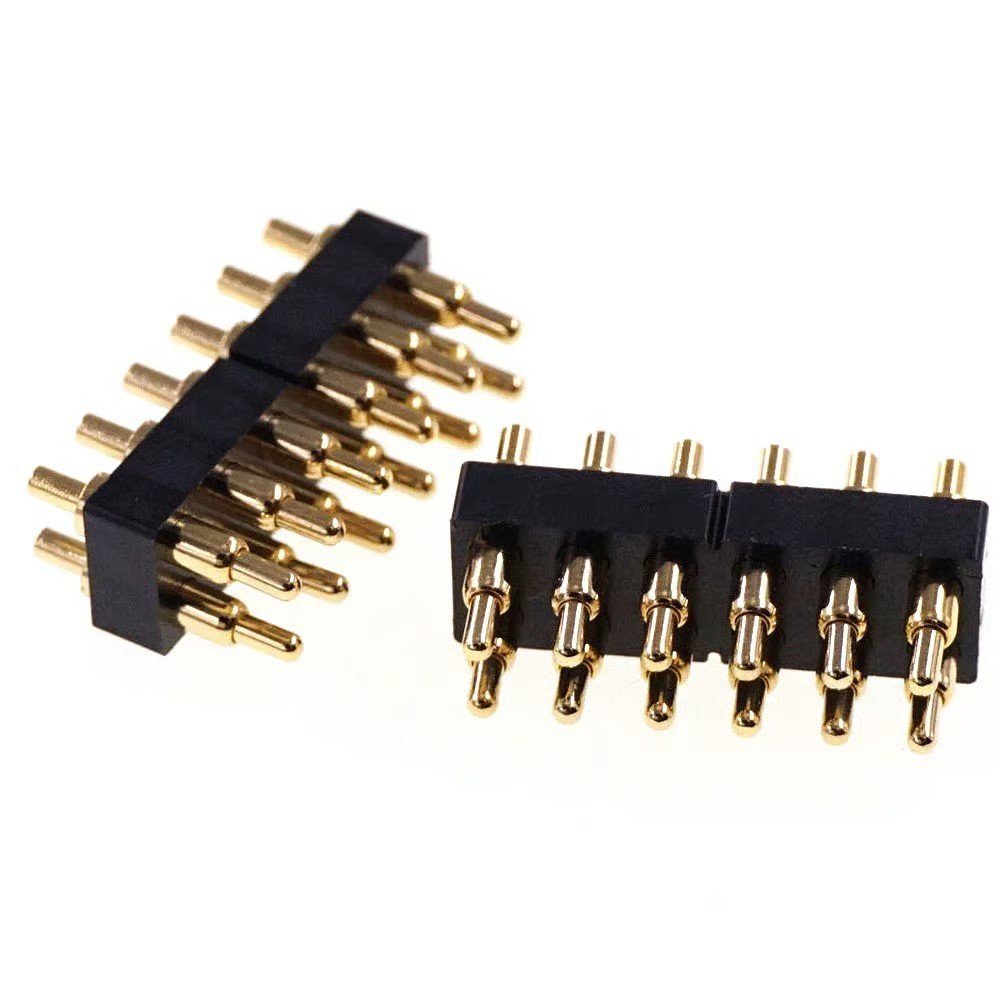

- Through Hole Pogo Pin Connector

Through Hole Pogo Pin Connector Manufacturing

High-reliability DIP spring-loaded connectors engineered for robust PCB applications. Our through hole mounting provides superior mechanical strength for demanding environments.

Get Custom QuoteThrough Hole Mounting Advantages

Superior Strength

Excellent mechanical retention through PCB holes

Vibration Resistant

Ideal for automotive and industrial applications

High Current

Support power applications up to 8A per pin

Easy Rework

Serviceable design for repair and replacement

Technical Specifications

Pitch Range

2.0mm, 2.54mm standard pitches and custom options

Hole Diameter

0.8mm to 2.0mm depending on pin size

Height Range

6.0mm to 20.5mm overall heights available

Pin Configuration

Single row, dual row, 2 to 12 positions

Temperature

-40°C to +125°C operating range

Through Hole Pogo Pin Product Range

Robust DIP connector solutions

Brass Gold Plated

Male and female electrical connectors for PCB

12-Pin Dual Row

2×6 through hole 2.54mm grid DIP connector

High Current 8A

12V DIP spring loaded power connectors

6.0mm Height

Straight flange single spring-loaded contact

Standard Through Hole

Reliable spring-loaded PCB connectors

Multi-Position Arrays

Custom through hole configuration options

Rapidaccu Quality Manufacturing

Located in Shenzhen, China, Rapidaccu delivers precision-engineered through hole pogo pin connectors that exceed international quality standards. Our advanced CNC machining capabilities ensure consistent performance and reliability.

Key Applications

Automotive

Industrial

Aerospace

Telecom

Testing

Medical

Power

Defense

Equipment

Marine

Frequently Asked Questions

What are the advantages of through hole pogo pin connectors?

What hole size is required for through hole pogo pins?

Can through hole pogo pins be used with wave soldering?

What current ratings are available for through hole pogo pin connectors?

Request Your Through Hole Pogo Pin Connector Quote

Robust DIP solutions for demanding applications

Contact Rapidaccu

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

Over 15 Years in Pogo Pin and Connector Manufacturing