- Home ›

- CNC Metal Machining ›

- Titanium

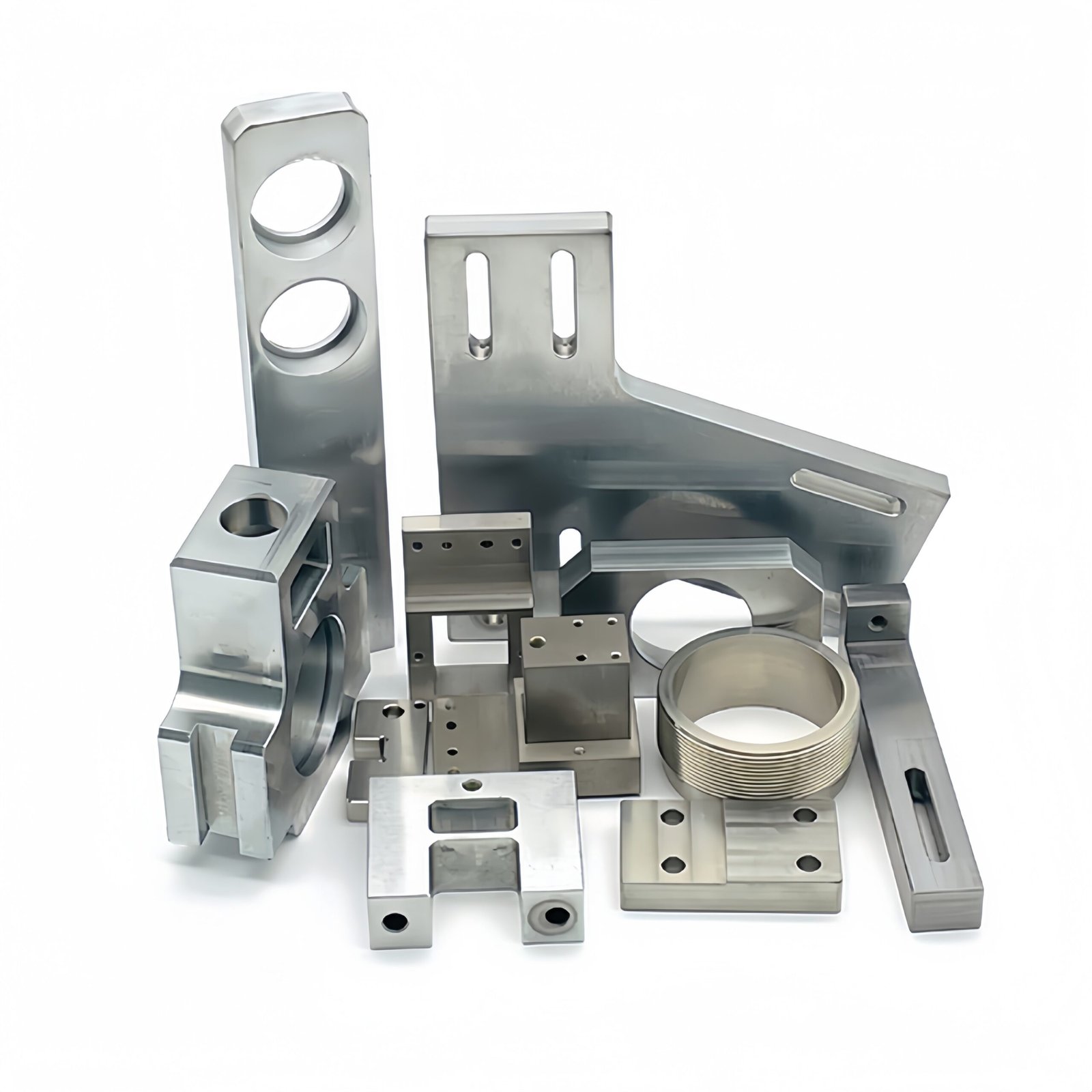

Custom CNC Machining Titanium Parts

Premium titanium machining services with exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility for aerospace, medical, and high-performance applications.

Why Choose Rapidaccu for Titanium CNC Machining?

Located in Shenzhen, China’s manufacturing hub, Rapidaccu has been delivering precision titanium machining solutions for over 15 years, serving aerospace, medical, and industrial clients worldwide.

Advanced Equipment

State-of-the-art 3, 4, and 5-axis CNC machines specifically configured for titanium machining with proper coolant systems and sharp carbide tooling.

ISO Certified Quality

ISO 9001:2015 certified facility with comprehensive quality control processes ensuring consistent precision and reliability for critical applications.

Global Logistics

Efficient shipping from Shenzhen with comprehensive packaging for delicate titanium parts, ensuring safe delivery worldwide.

Titanium Material Properties & Advantages

Understanding why titanium is the material of choice for demanding applications

Exceptional Strength-to-Weight Ratio

Titanium is 40% lighter than steel while maintaining comparable strength, making it ideal for aerospace and automotive applications where weight reduction is critical.

Superior Corrosion Resistance

Titanium forms a protective oxide layer that provides excellent resistance to seawater, chemicals, and harsh environments.

Biocompatibility

Non-toxic and biocompatible, titanium is widely used in medical implants, surgical instruments, and dental applications.

High Temperature Performance

Maintains strength and stability at elevated temperatures, suitable for aerospace engines and high-temperature industrial applications.

ASTM Titanium Grades Comparison

Comprehensive guide to titanium alloy specifications and applications

| Grade | Composition | Tensile Strength (MPa) | Yield Strength (MPa) | Typical Applications | Cost Level |

|---|---|---|---|---|---|

| Ti Grade 1 | 99.5% Ti (CP) | 240 | 170 | Chemical processing, marine hardware, architectural applications | Low |

| Ti Grade 2 | 99.2% Ti (CP) | 345 | 275 | General purpose, heat exchangers, pressure vessels, fasteners | Low |

| Ti Grade 5 (Ti-6Al-4V) | 6% Al, 4% V, 90% Ti | 895-930 | 828 | Aerospace components, automotive parts, medical implants | Medium |

| Ti Grade 9 (Ti-3Al-2.5V) | 3% Al, 2.5% V, 94.5% Ti | 620 | 520 | Tubing, pressure vessels, aircraft hydraulics | Medium |

| Ti Grade 23 (Ti-6Al-4V ELI) | 6% Al, 4% V, Extra Low Interstitial | 860 | 795 | Medical implants, surgical instruments, prosthetics | High |

Titanium CNC Machining Applications

Serving critical industries with precision titanium components

Aerospace

- Aircraft engine components

- Landing gear parts

- Structural brackets

- Fasteners and fittings

Medical

- Orthopedic implants

- Surgical instruments

- Dental implants

- Prosthetic components

Automotive

- Performance engine parts

- Exhaust system components

- Suspension components

- Racing vehicle parts

Marine

- Propeller shafts

- Valve components

- Heat exchangers

- Pump housings

Industrial

- Chemical processing equipment

- Power generation components

- Oil & gas equipment

- High-temperature applications

Sports & Recreation

- Golf club heads

- Bicycle frames

- Sporting equipment

- Performance accessories

Advanced Titanium Machining Capabilities

Specialized equipment and techniques for superior titanium processing

Multi-Axis CNC Machining

Our 3, 4, and 5-axis CNC machines enable complex geometry machining with minimal setups, reducing handling and improving accuracy for intricate titanium components.

- 3-axis milling for basic operations

- 4-axis for cylindrical features

- 5-axis for complex geometries

Specialized Tooling

Sharp carbide tools, proper cutting parameters, and flood coolant systems optimized specifically for titanium’s unique machining characteristics.

- Carbide end mills with sharp cutting edges

- Flood coolant for heat management

- Low cutting speeds, high feed rates

Quality Control

Advanced inspection equipment including CMM, surface roughness testers, and dimensional verification systems ensure every part meets specifications.

- Coordinate measuring machines (CMM)

- Surface roughness measurement

- First article inspection (FAI)

Frequently Asked Questions

Common questions about titanium CNC machining services

What makes titanium difficult to machine?

Which titanium grade should I choose for my application?

What tolerances can you achieve with titanium machining?

Do you provide material certification for titanium parts?

What is the typical lead time for titanium CNC parts?

Can you handle both prototypes and production quantities?

Get Your Titanium Parts Quote Today

Ready to discuss your titanium CNC machining project? Our experienced engineers are here to help you achieve precision results.