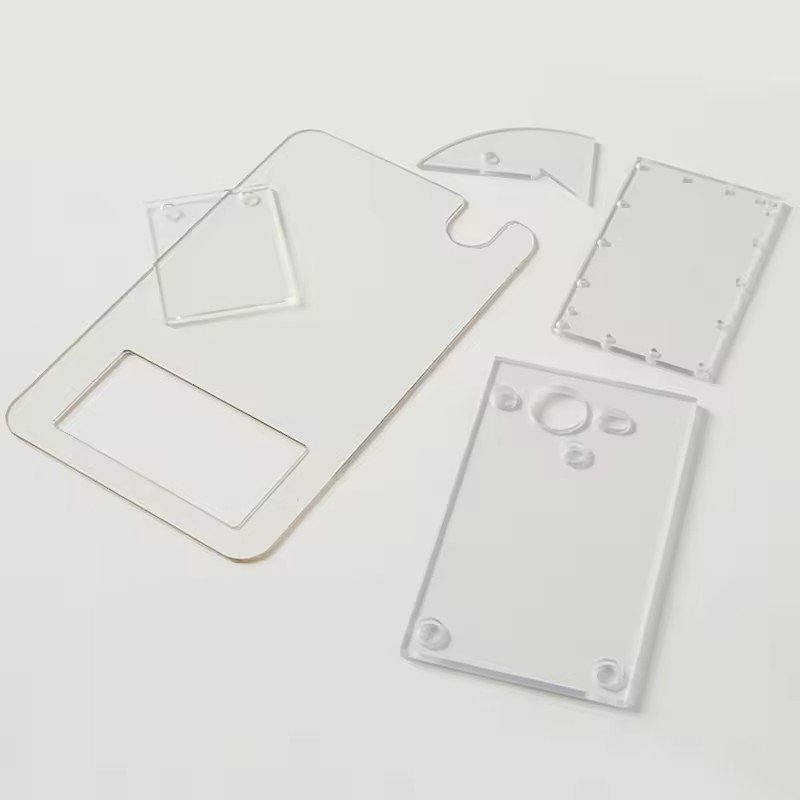

Custom CNC Machining Acrylic Parts

Professional precision PMMA machining services with 15 years of expertise. We deliver high-quality custom acrylic parts for optical, medical, automotive, and industrial applications.

Fast Delivery

3-7 Days

High Precision

±0.002″

15 Years

Experience

ISO 9001:2015

Certified Quality

Why Choose Rapidaccu for Acrylic CNC Machining?

We are a leading CNC machining manufacturer in China, specializing in custom acrylic parts with unmatched precision and quality.

Advanced Equipment

State-of-the-art 3, 4, and 5-axis CNC machines for complex geometries

Optical Clarity

92% light transmission with superior optical properties

Quality Certified

ISO 9001:2015 certified with 100% quality inspection

Global Shipping

Fast worldwide delivery from Shenzhen, China

About Acrylic (PMMA) CNC Machining

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic known for its exceptional optical clarity, strength, and UV stability. Our precision CNC machining services transform raw acrylic materials into complex custom parts.

Superior Optical Properties

92% light transmission with refractive index of 1.49

Excellent Machinability

Easy to machine with complex geometries and tight tolerances

Weather Resistant

UV stable and chemical resistant for outdoor applications

Acrylic Material Grades & Applications

Compare different ASTM acrylic grades and their optimal applications

| ASTM Grade | Properties | Applications | Cost Level | Lead Time |

|---|---|---|---|---|

| PMMA Cast | Higher molecular weight, better optical clarity, stress resistance | Optical lenses, medical devices, precision instruments | High | 5-7 days |

| PMMA Extruded | Lower cost, good optical properties, easier to machine | Display cases, signage, light diffusers, prototypes | Medium | 3-5 days |

| Impact Modified | Enhanced impact resistance, slightly reduced clarity | Automotive glazing, safety applications, outdoor panels | Medium+ | 4-6 days |

| UV Stabilized | Enhanced UV protection, long-term outdoor stability | Architectural glazing, greenhouse panels, outdoor displays | Medium+ | 4-6 days |

| Flame Retardant | UL94 V-0 rating, self-extinguishing properties | Electronics enclosures, aircraft interiors, safety covers | High | 6-8 days |

Industries & Applications

Our precision acrylic machining serves diverse industries worldwide

Medical & Laboratory

- • Microfluidic devices

- • Optical lenses

- • Medical enclosures

- • Laboratory equipment

Automotive

- • Headlight lenses

- • Interior trim

- • Instrument panels

- • Light guides

Lighting & Optics

- • LED light diffusers

- • Optical fibers

- • Light pipes

- • Fresnel lenses

Electronics

- • Display covers

- • Equipment enclosures

- • Touch screen protectors

- • Optical waveguides

Architecture

- • Glazing panels

- • Decorative elements

- • Canopies

- • Safety barriers

Research & Development

- • Prototype components

- • Testing fixtures

- • Custom housings

- • Optical test parts

Our CNC Machining Capabilities

Advanced equipment and processes deliver precision acrylic parts to your exact specifications.

Precision Tolerances

±0.002″ achievable

Surface Finish

Ra 0.1-3.2μm

Material Thickness

0.5mm – 200mm

Part Size

Up to 1500x800mm

Precision Manufacturing

State-of-the-art CNC equipment ensures consistent quality and accuracy for every part we produce.

Frequently Asked Questions

Common questions about our acrylic CNC machining services

What tolerances can you achieve with acrylic CNC machining?

What is the typical lead time for custom acrylic parts?

What surface finishes are available for acrylic parts?

Can you machine complex geometries in acrylic?

What file formats do you accept for quotes?

Do you provide material certificates and quality reports?

Get Your Custom Acrylic Parts Quote

Contact our engineering team for expert consultation and competitive pricing on your acrylic CNC machining project.

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comResponse Time

We respond to all inquiries within 24 hours

Experience

15+ years in precision CNC machining