- Home ›

- CNC Plastic Machining ›

- Custom CNC Machining PET Parts

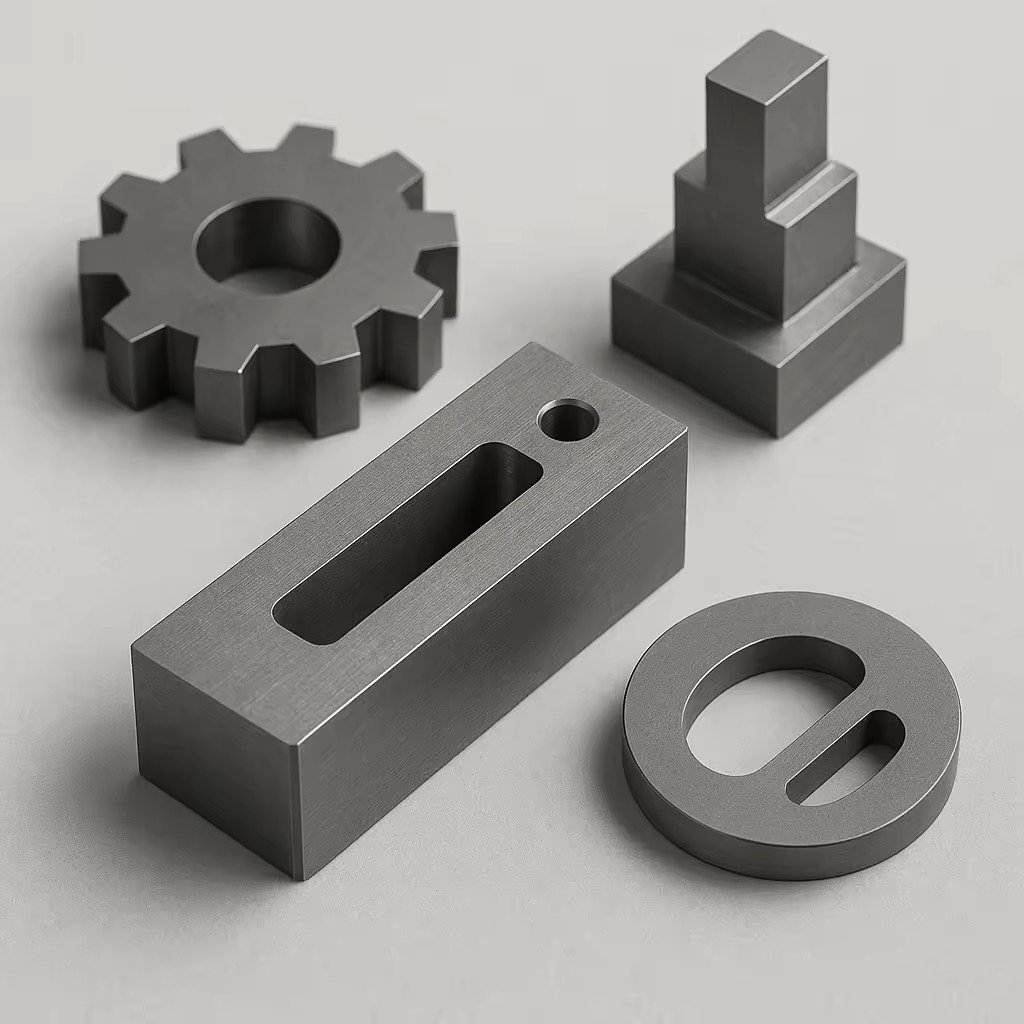

Precision CNC Machining PET Parts

Professional polyethylene terephthalate (PET) CNC machining services with ±0.002″ precision tolerance. 15+ years experience manufacturing high-quality PET components for demanding applications.

Why Choose PET for CNC Machining?

Polyethylene Terephthalate (PET) offers exceptional mechanical properties, chemical resistance, and dimensional stability, making it ideal for precision components.

High Strength-to-Weight Ratio

Excellent mechanical strength while remaining lightweight, perfect for demanding structural applications.

Chemical Resistance

Outstanding resistance to acids, bases, and solvents, ideal for harsh chemical environments.

Dimensional Stability

Maintains shape and size under varying environmental conditions for consistent performance.

Excellent Machinability

Easy to machine with standard cutting tools, allowing for intricate designs and tight tolerances.

Temperature Stability

Good thermal properties with continuous service temperature up to 80°C (176°F).

Optical Clarity

Available in transparent grades with excellent optical properties for visual applications.

PET Material Grades & Specifications

Comprehensive comparison of ASTM standard PET grades with application recommendations and cost analysis.

| ASTM Grade | Tensile Strength (MPa) | HDT (°C) | Typical Applications | Cost Level |

|---|---|---|---|---|

| PET-GF30 | 140-160 | 220-240 | Automotive components, electrical housings, structural parts | High |

| PET-GF15 | 100-120 | 180-200 | Electronic components, gears, bushings | Medium-High |

| PET Crystalline | 80-90 | 70-80 | Food packaging, medical devices, chemical tanks | Medium |

| PETG | 50-65 | 65-75 | Display panels, protective covers, consumer goods | Medium |

| PET Amorphous | 55-75 | 75-85 | Bottles, containers, optical components | Low-Medium |

Industry Applications

Our precision PET machining serves diverse industries with custom components meeting stringent quality standards.

Automotive

- Engine components

- Interior trim parts

- Electrical housings

- Fuel system components

Medical Devices

- Surgical instruments

- Diagnostic equipment

- Laboratory containers

- Medical implants

Electronics

- Insulators & connectors

- Circuit board supports

- Display components

- Electronic housings

Food & Beverage

- Processing equipment

- Food containers

- Packaging machinery

- Conveyor components

Chemical Processing

- Chemical tanks

- Pump components

- Valve parts

- Corrosion-resistant fittings

Consumer Products

- Appliance components

- Sporting goods

- Tool handles

- Protective covers

Advanced CNC Machining Capabilities

State-of-the-art equipment and expert engineering deliver precision PET components with exceptional quality and consistency.

Frequently Asked Questions

Common questions about our PET CNC machining services and capabilities.

What are the key advantages of PET for CNC machining applications?

What tolerances can you achieve with PET CNC machining?

What PET grades do you work with for different applications?

What is the typical lead time for custom PET machined parts?

Do you provide surface finishing options for PET parts?

What quality certifications does Rapidaccu maintain?

Get Your Custom Quote Today

Ready to start your PET CNC machining project? Contact our expert team for personalized service and competitive pricing.

Contact Information

Rapidaccu Manufacturing

Professional CNC Machining Services

15+ Years Experience in Precision Manufacturing

Factory Address

Rongli Industrial Park

Dalang, Longhua District

Shenzhen, China

Business Hours

Monday – Friday: 8:00 AM – 6:00 PM (CST)

Saturday: 9:00 AM – 4:00 PM (CST)

Why Choose Rapidaccu?

- 15+ years precision machining experience

- ISO 9001:2015 & IATF 16949 certified

- Advanced 5-axis CNC equipment

- Competitive pricing from China

- Fast turnaround & global shipping