Custom Aerospace Components & Parts Manufacturing

Precision CNC machining for mission-critical aerospace components. 15+ years of expertise in manufacturing turbine blades, landing gear parts, brackets, and complex assemblies for commercial and military aviation.

Why Choose Rapidaccu for Aerospace Manufacturing

Excellence in precision, reliability in delivery, innovation in solutions

15+ Years Experience

Extensive expertise in aerospace component manufacturing with proven track record in delivering critical parts for commercial and military applications.

Precision Tolerances

Advanced 5-axis CNC machining capabilities achieving tolerances down to ±0.0001 inches for the most demanding aerospace specifications.

Quality Certified

ISO 9001:2015 and AS9100 certified manufacturing processes ensuring the highest quality standards for aerospace applications.

Advanced Manufacturing Capabilities

State-of-the-art equipment and processes for complex aerospace components

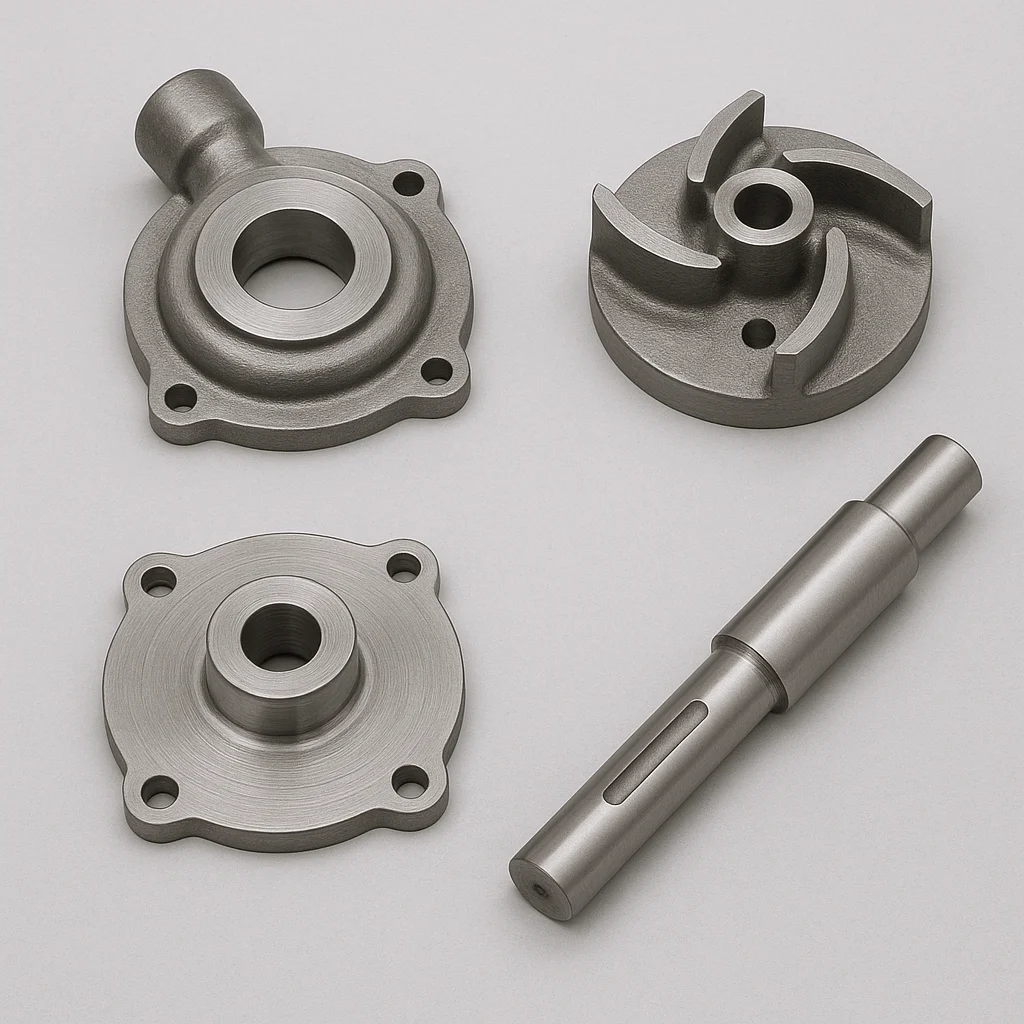

Precision CNC Machining Services

Multi-Axis CNC Machining

3, 4, and 5-axis CNC machining for complex geometries and tight tolerances

Exotic Material Processing

Titanium, Inconel, aluminum alloys, and specialty aerospace materials

Surface Finishing

Anodizing, passivation, and specialized coatings for aerospace applications

Manufacturing Capabilities Overview

| Capability | Specification | Materials | Applications |

|---|---|---|---|

| CNC Milling | 3-5 Axis, ±0.0001″ tolerance | Aluminum, Titanium, Inconel | Structural components, brackets |

| CNC Turning | Ø0.5-500mm, ±0.0002″ tolerance | Stainless steel, exotic alloys | Shafts, pins, bushings |

| EDM Machining | Wire & Sinker EDM | Hardened steels, carbides | Complex geometries, cooling holes |

| Swiss Machining | Ø0.1-32mm precision parts | All aerospace materials | Small precision components |

| Assembly Services | Sub-assembly & final assembly | Multi-material assemblies | Complete system integration |

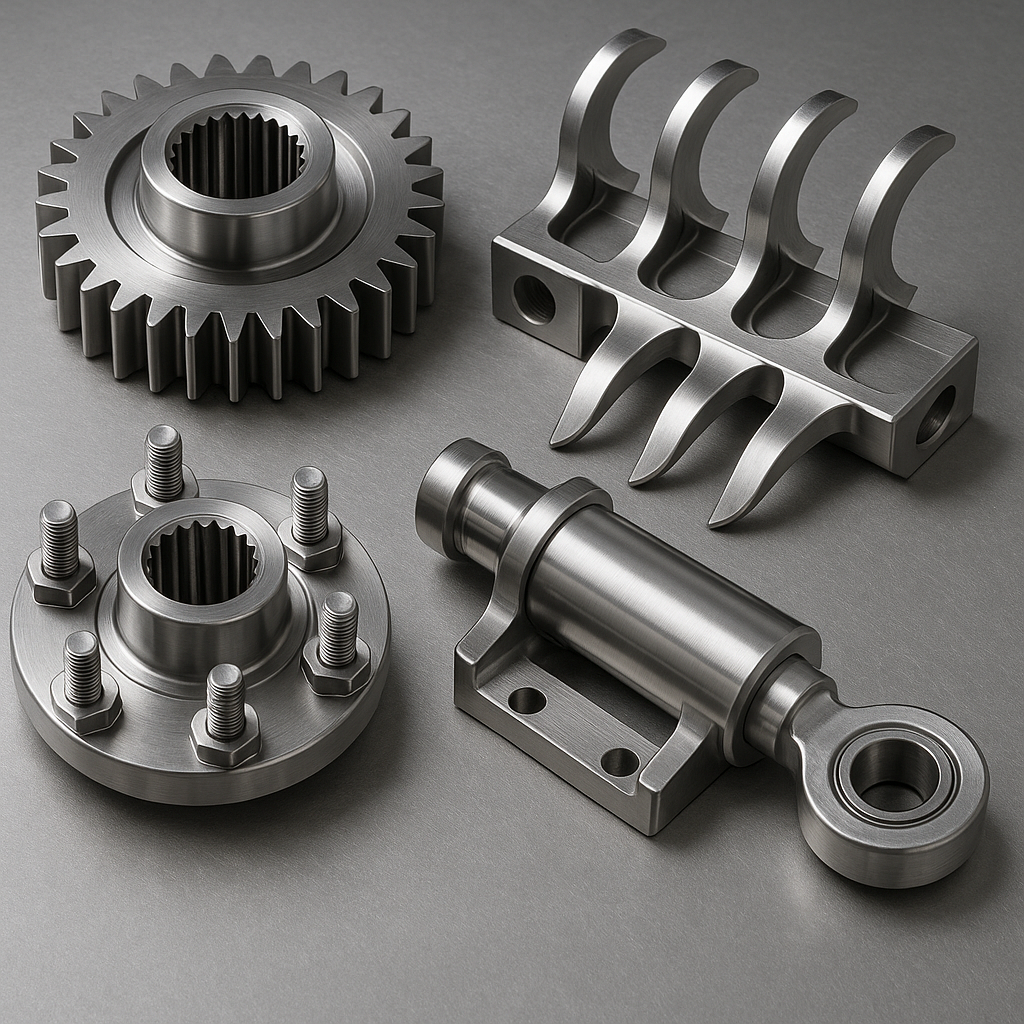

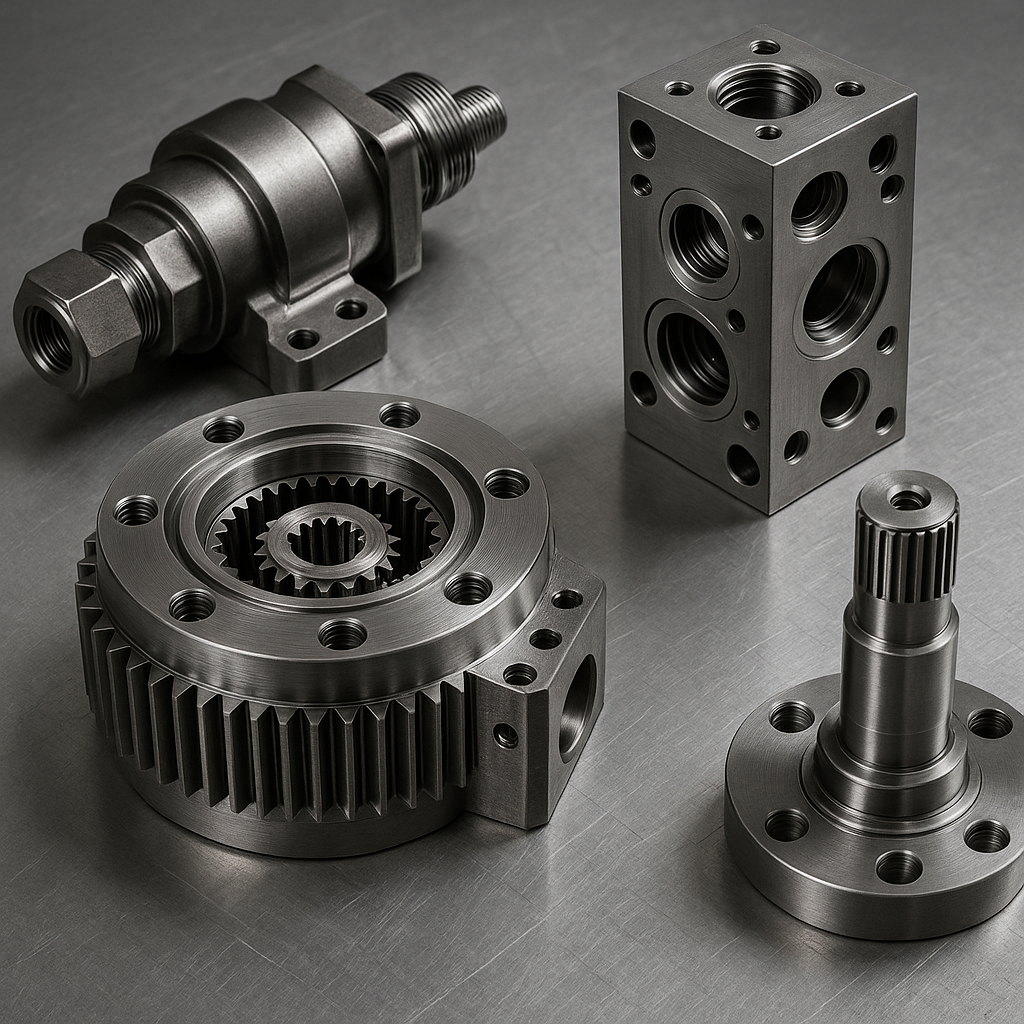

Common CNC Aerospace Parts We Manufacture

Specialized in critical flight components for commercial and military aviation

Engine Components

- Turbine blades & vanes

- Compressor discs

- Fuel nozzles & manifolds

- Heat exchangers

Structural Parts

- Airframe brackets

- Wing ribs & spars

- Fuselage components

- Control surface parts

Landing Gear Systems

- Landing gear struts

- Brake components

- Actuator housings

- Retraction mechanisms

Avionics & Electronics

- Avionics housings

- Heat sinks & enclosures

- Connector assemblies

- Antenna components

Hydraulic Systems

- Hydraulic manifolds

- Valve bodies

- Actuator components

- Filter housings

Specialized Components

- Satellite components

- Space vehicle parts

- Missile components

- Radar system parts

Materials & Standards

Working with aerospace-grade materials to the highest industry standards

Certified Materials

Aluminum Alloys

- 6061-T6, 7075-T6

- 2024-T3, 5052-H32

- Mic-6 tooling plate

Titanium

- Ti-6Al-4V Grade 5

- Ti Grade 2 & Grade 9

- Beta-C titanium

Superalloys

- Inconel 625, 718

- Hastelloy X

- Waspaloy

Stainless Steel

- 316L, 17-4 PH

- 15-5 PH, 13-8 Mo

- Custom 450, 455

Quality Standards

AS9100 Rev D Certified

Aerospace quality management system

ISO 9001:2015

International quality management standard

ITAR Compliance

Defense trade regulations compliance

Material Traceability

Complete material certification & traceability

Frequently Asked Questions

Common questions about our aerospace manufacturing services

What tolerances can you achieve for aerospace components?

What certifications do you have for aerospace manufacturing?

Can you work with exotic aerospace materials like Inconel and titanium?

What is your typical lead time for aerospace components?

Do you provide assembly services for aerospace components?

Get Your Aerospace Components Quote

Ready to discuss your aerospace manufacturing project? Contact our experienced team for a detailed quote and technical consultation.

Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

15+ years in precision aerospace manufacturing