One in three engineers has to revise a design after a part fails thermal tests, and ignoring a basic numeric threshold causes many of those fixes.

This guide starts with a clear baseline: elemental aluminum melts at 1220.58°F (660.32°C). That figure sets a reference for alloys, production choices, and safe operating windows.

Design teams prize strength-to-weight ratio, corrosion resistance, and heat-sink properties. Still, overlooking this key temperature can harm quality, safety, and dimensional accuracy during fabrication or service.

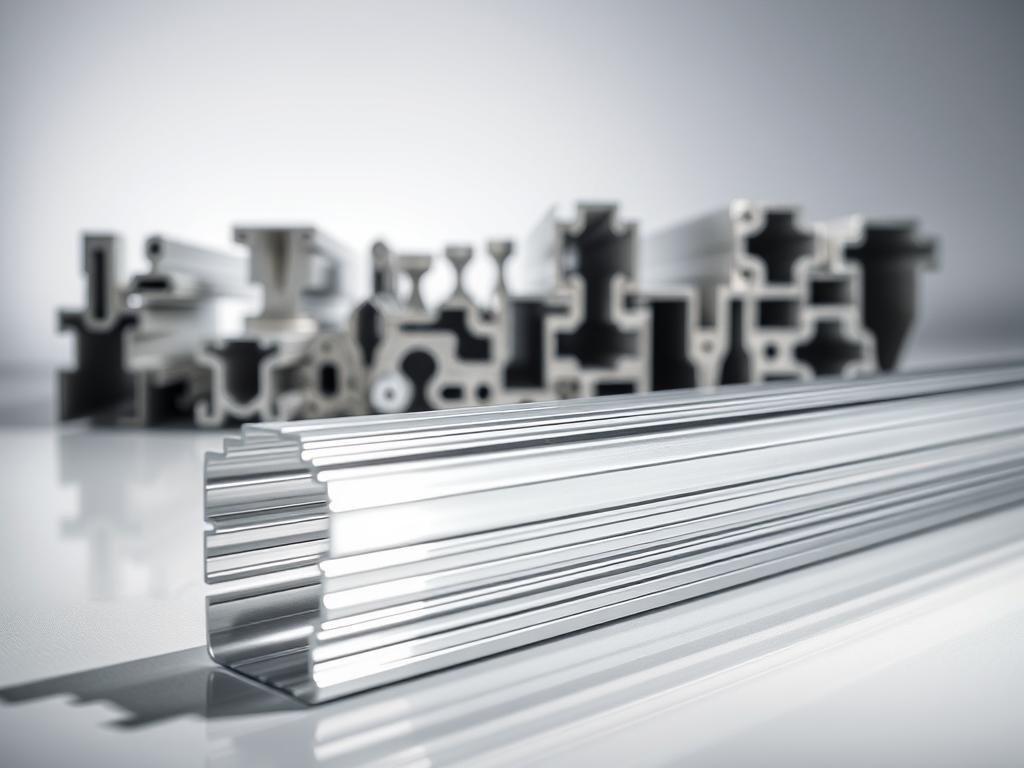

We preview how alloys shift from a single value to a range, why that matters for casting and extrusion, and how Rapidaccu uses this data when planning toolpaths and selecting materials for prototypes and mass runs.

Read on to get practical facts, alloy-specific ranges, and production-focused advice that helps U.S. engineers and buyers make better procurement and design decisions.

Aluminum Melting Point Basics and Why It Matters in Manufacturing

Rapidaccu uses a precise thermal baseline to help teams avoid process failures and scrap. Pure aluminum transitions from solid to liquid at 1220.58°F (660.32°C). That fusion temperature informs furnace setup, joining choices, and safety margins.

Compared with other materials, this value sits about twice zinc’s and roughly half common stainless steel. Those contrasts affect furnace selection and whether to braze, weld, or cast parts.

- High thermal conductivity spreads heat quickly, so machining feeds, coolant choice, and fixturing must limit local hot spots.

- Strength loss begins well below the fusion mark; many alloys weaken several hundred degrees earlier, changing tolerances.

- Accurate melt data guides soldering, brazing, and heat-treatment windows and supports incoming material certification.

| Metric | Pure Value | Typical Handling Range | Manufacturing Note |

|---|---|---|---|

| Melting point | 1220.58°F (660.32°C) | 1300–1450°F (furnace work) | Set furnace and safety margins accordingly |

| Comparison metal (zinc) | ~787°F (419°C) | Lower melting, different fluxing | Affects choice of joining method |

| Comparison steel | ~2575–2750°F (stainless) | Higher handling temps | Requires different furnaces and shields |

During DFM reviews, Rapidaccu pairs these numbers with conductivity data to set feeds, speeds, and fixturing. That workflow helps preserve finish and dimensional accuracy while meeting certification and traceability needs.

whats is the aluminum melting point for alloys versus pure aluminum

Alloying turns a crisp fusion value into a spread of temperatures that manufacturers must plan around.

Melting point depression: why alloys have melting ranges, not single points

Adding alloying elements lowers and spreads the solidus-liquidus gap. Copper, zinc, silicon and magnesium create phases that melt at different temps, so most parts show a range rather than a single mark.

Common wrought alloy ranges

Typical wrought ranges (°F): 1100: 1190–1215; 2024: 935–1180; 3003: 1190–1210; 5052: 1125–1200; 5456: 1055–1180; 6061: 1080–1205; 7075: 890–1175.

Popular cast alloy ranges and uses

Cast ranges (°F): A360 1030–1100, A380 1000–1100, A413 1070–1080, B390 950–1200. Use cases: A380 for housings, A360 for instrument cases, A413 for pistons, B390 for engine parts.

| Alloy | Range (°F) | Typical Use |

|---|---|---|

| 6061 | 1080–1205 | Machined structural parts |

| 7075 | 890–1175 | Aerospace high-strength |

| A380 | 1000–1100 | Gear cases, housings |

| B390 | 950–1200 | Engine components |

Impurities and recycled feedstock can shift ranges unpredictably. Rapidaccu recommends tighter incoming QC for critical runs and selecting an alloy family that balances machinability, dimensional stability, and thermal behavior.

Example workflow: choose 6061 for balanced machining and safer thermal margins; pick 7075 only when strength outweighs narrower handling windows. Always target furnace settings to cover the full range, not just a midpoint.

Factors That Affect Aluminum Melting Temperature

Multiple material variables change how and when a billet softens under heat during processing.

Alloy composition and element effects

Magnesium, silicon, zinc, and copper each lower solidus values and widen thermal ranges. Small shifts in alloy targets can move handling windows by tens of degrees.

Chemical impurities and variation signals

Impurities cause melting depression; a variance over 41°F signals contamination and should trigger further inspection.

Rapidaccu requires supplier certificates and documented impurity levels so machining plans reflect real behavior and reduce rework.

Pressure, particle size, and bonding forces

Extreme pressure can alter phase behavior, though shop pressures rarely reach that regime. Nanoscale powder and fine chips show lower observed thresholds because surface energy and bonding change required energy.

- Tight charge composition and degassing stabilize melting ranges.

- Document heat chemistry to predict consistent properties and downstream machinability.

- Use conservative soak cycles for alloys with narrow solidus–liquidus spreads to avoid incipient melt.

| Factor | Effect | Shop action |

|---|---|---|

| Alloying elements | Lower solidus, widen range | Specify targets; adjust furnace window |

| Impurities | Depress fusion >41°F | Reject or recondition charge |

| Particle size / bonding | Lower thresholds for powders | Control recycling and powder specs |

From Bauxite to Billet: Production, Melting, and Casting Processes

Raw bauxite travels a long path before it becomes billet-ready stock for casting and extrusion shops. Miners refine ore to alumina (Al₂O₃), then use electrolysis via the Hall-Héroult process to free metal without directly heating alumina to its much higher fusion level.

Alumina and the Hall-Héroult process

Alumina melts near 3,762°F, so smelters rely on electrolysis to separate metal efficiently. That route avoids massive energy losses and keeps downstream furnaces sized for practical temperatures used by casthouses.

Melting safely and furnace practices

Molten handling commonly runs 1300–1450°F to balance flow and solidification during casting. Casthouses charge prime metal first, add scrap once prime is fluid, then introduce hardeners like silicon and magnesium to meet alloy specs.

- Fluxing, inert-gas degassing, filtration, and settling cut impurities and stabilize chemistry.

- Keep water away from molten pools; use PPE and molten-metal protocols to prevent explosions.

- Furnace controls target yield and lower energy use while maintaining consistent temperatures to reduce scrap.

Casting, extrusion, and forming process windows

Knowledge of fusion behavior guides gating, die preheat, and pour temperature to avoid cold shuts, porosity, and shrinkage. Billet preheat for extrusions and die selection match those windows so aluminum extrusions meet dimensional and surface targets.

| Stage | Typical Temp (°F) | Key Action |

|---|---|---|

| Casthouse melt | 1300–1450 | Charge prime, add scrap, tune alloy |

| Casting pour | 1350–1420 | Gating design, filtration, flux |

| Billet preheat (extrusion) | 900–1150 | Die preheat, quench strategy |

Rapidaccu partners with certified suppliers and casthouses to source reliable billets and plate, then applies controlled machining strategies aligned with melting-aware process windows to keep finish and tolerances consistent. For more background on thermal baselines, see this reference on melting behavior.

Performance at Elevated Temperatures: Strength, Creep, and Design Limits

Heat exposure around 300–400°F can change part behavior enough to trigger premature service issues.

Many alloys lose a large fraction of their rated strength at these temperatures. That reduction happens well before any melting point is approached and can allow creep under sustained load.

Creep causes slow deformation and dimensional drift. Small components under constant stress may shift out of tolerance over months of operation.

- Cookware: good thermal conduction but risk of local overheating and loss of form when left on high heat.

- Automotive: engine and transmission parts need alloys chosen for sustained service temperatures.

- Aerospace: assemblies require alloys and tempers that retain strength and resist fatigue at operating temperatures.

Magnesium- and zinc-bearing alloys often need stricter thermal controls during joining and finishing. Coatings and surface treatments change heat absorption and can help or hurt dissipation.

Rapidaccu advises qualification testing across expected temperatures and uses coolant selection, optimized toolpaths, and robust fixturing to limit heat input during machining. That preserves strength, surface integrity, and final tolerances for critical applications.

Applying Melting Point Knowledge to Precision CNC Machining with Rapidaccu

Controlling chip temperature during CNC work prevents dimensional surprises and improves surface quality from prototype to production.

Choosing alloys for machining and finish

Pick 6061 when you want good machinability and consistent surface finish. Use 7075 for high strength where tight tolerances beat ease of cut. 2024 fits aerospace uses that need fatigue resistance but may need special cooling to limit thermal distortion.

Prototyping to production: managing heat and distortion

Rapidaccu applies a DFM workflow that sets feeds, speeds, and coolant cycles to avoid incipient softening and brittle skin formation. Fixturing and toolpath sequencing reduce heat build-up in thin-wall sections and high-aspect features.

- Use billet with clean chemistry and documented heat lots for stable chip formation.

- Favor extrusions or machined extrusions when supply chain and geometry make them a better starting form.

- Document alloy certificates and lot traceability so runs stay consistent across scale.

| Feature | Shop action | Benefit |

|---|---|---|

| Thin-wall | Light passes, chilled fixtures | Less warpage |

| High-strength alloy | Lower chip load, slower ramps | Maintain tolerances |

| Extrusion start | Align process windows | Faster turnup to product |

Conclusion

Knowing exact fusion behavior helps teams pick alloys and set safe process windows before cutting or casting begins.

Pure metal melts near 1220.58°F (660.32°C), while most alloys show a range because of added elements and possible impurities. Recycled content, particle size, and pressure can also shift those values.

In practice, set conservative furnace targets, respect solidus–liquidus windows, and watch for >41°F variation as an impurity signal. Design parts for service temperatures — strength loss can appear far below any fusion mark.

Compared to steel and other metals, lower fusion numbers aid recycling and energy use, but they demand careful heat control in casting, extrusion, machining, and heat treatment.

Rapidaccu’s 15+ year CNC team can help select alloy, plan the right process, and deliver precise parts from prototype to production.