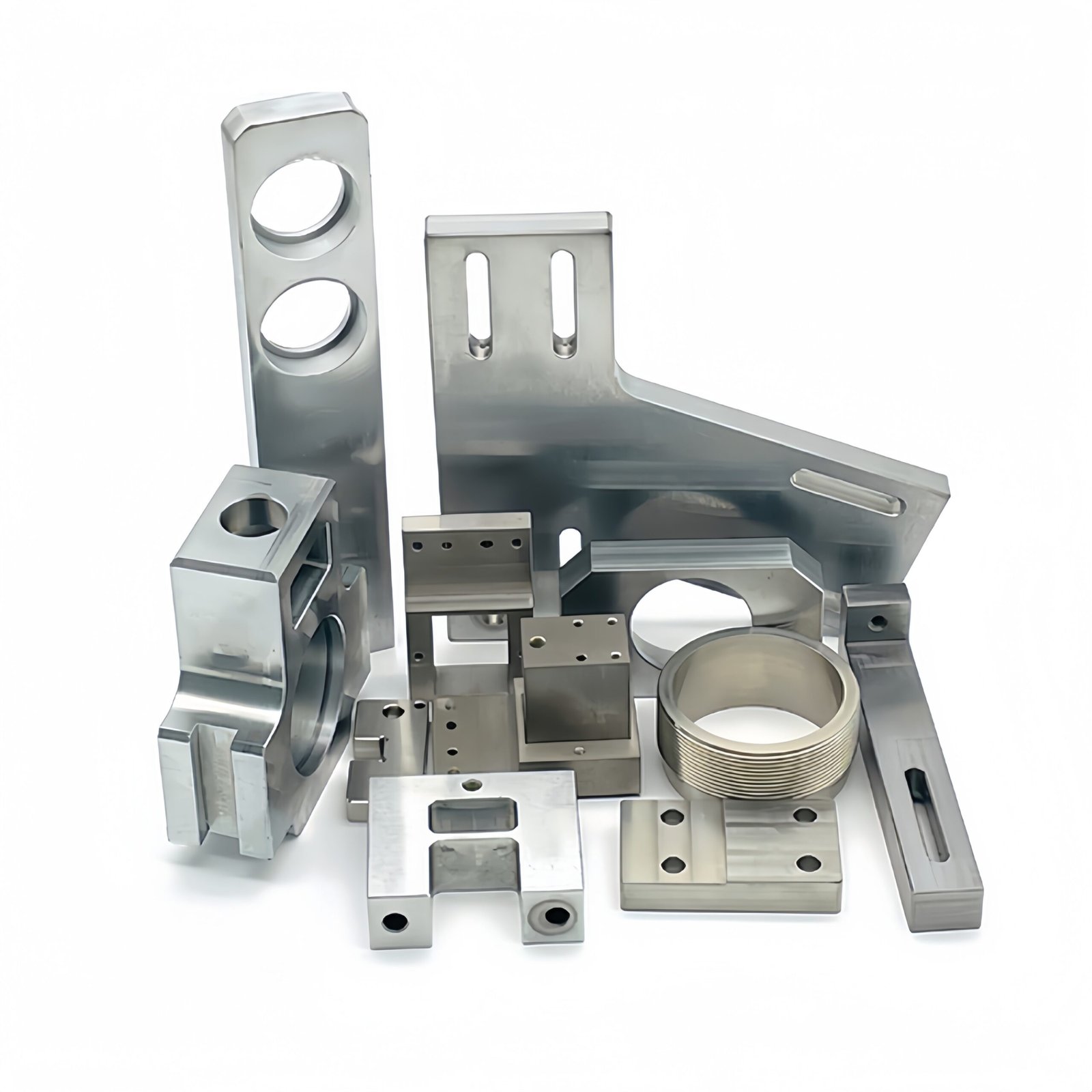

Professional CNC Metal Machining Services

Rapidaccu delivers precision CNC metal machining services with 15+ years of manufacturing expertise. From prototypes to production runs, we machine high-quality metal parts to exact specifications.

Why Choose Rapidaccu for CNC Metal Machining?

We combine advanced CNC technology with skilled craftsmanship to deliver superior metal parts that meet the most demanding specifications across various industries.

Precision Engineering

State-of-the-art CNC machines ensure consistent accuracy with tolerances as tight as ±0.005mm for critical metal components.

Quality Assurance

ISO 9001 certified processes with comprehensive quality control measures throughout every stage of production.

Expert Team

15+ years of experience with skilled engineers and machinists who understand complex metal machining requirements.

Material Expertise

Comprehensive knowledge of metal properties and machining characteristics across aluminum, steel, titanium, and exotic alloys.

Industry Compliance

Meeting stringent industry standards for aerospace, medical, automotive, and defense applications.

Customer Support

Dedicated project management and technical support throughout your entire metal machining project lifecycle.

Our Metal Machining Capabilities

Rapidaccu offers comprehensive metal machining services using advanced CNC equipment and specialized processes to meet diverse manufacturing requirements.

CNC Machining

- 3, 4, and 5-axis CNC milling

- CNC turning and lathe services

- Swiss machining for complex parts

- Micro machining capabilities

- Prototype to production volumes

Wire EDM Services

- High-precision wire cutting

- Complex geometries and tight tolerances

- Hard metal processing

- Intricate internal features

- Superior surface finish

Surface Treatment

- Anodizing for aluminum parts

- Powder coating and painting

- Passivation for stainless steel

- Electroplating services

- Custom finishing solutions

CNC Metal Materials We Machine

Our expertise spans a wide range of metals and alloys, each machined with specialized techniques to optimize performance and quality for your specific applications.

Aluminum

Lightweight, corrosion-resistant, excellent for aerospace and automotive applications with superior machinability.

Learn More →

Bronze

Excellent wear resistance and thermal conductivity, ideal for bushings, bearings, and marine applications.

Learn More →

Cast Iron

High strength and excellent vibration damping properties, perfect for heavy-duty industrial components.

Learn More →

Copper

Superior electrical and thermal conductivity, antimicrobial properties for electrical and medical devices.

Learn More →

Nitinol

Shape memory alloy with unique properties, specialized machining for medical and aerospace applications.

Learn More →

Stainless Steel

Corrosion resistance and strength, ideal for food processing, medical, and chemical industry components.

Learn More →

Titanium

Exceptional strength-to-weight ratio and biocompatibility, perfect for aerospace and medical implants.

Learn More →

Tool Steel

High hardness and wear resistance, specialized for cutting tools, dies, and precision tooling applications.

Learn More →Industries We Serve

Rapidaccu’s CNC metal machining expertise serves diverse industries with precision-engineered components that meet the most stringent quality and performance standards.

Aerospace

Critical flight components requiring exceptional precision and material performance standards.

Automotive

Engine components, transmission parts, and custom automotive solutions with tight tolerances.

Medical

Biocompatible implants, surgical instruments, and medical device components with FDA compliance.

Defense

Military-grade components meeting stringent defense specifications and security requirements.

Electronics

Precision housings, heat sinks, and electronic component parts with excellent conductivity.

Energy

Power generation components, renewable energy parts, and industrial energy solutions.

Marine

Corrosion-resistant marine hardware and components designed for harsh saltwater environments.

Industrial

Heavy machinery components, tooling, and industrial equipment parts built for durability.

Our CNC Metal Machining Process

From initial design consultation to final delivery, our systematic approach ensures consistent quality and precision in every metal component we manufacture.

Design Review

Our engineers analyze your specifications, CAD files, and requirements to optimize manufacturability and cost-effectiveness.

Material Selection

Choose from our extensive inventory of certified metals and alloys, with guidance on optimal material properties for your application.

CNC Programming

Advanced CAM programming creates optimized toolpaths for efficient machining while maintaining precision and surface quality.

Precision Machining

State-of-the-art CNC equipment executes the machining process with continuous monitoring for dimensional accuracy and quality.

Quality Inspection

Comprehensive dimensional inspection using CMM and precision measuring equipment ensures every part meets specifications.

Surface Treatment

Apply specified finishes and treatments to enhance corrosion resistance, appearance, and functional performance.

Final Inspection

Complete quality verification with detailed inspection reports and certificates of compliance before packaging.

Secure Delivery

Professional packaging and reliable shipping ensure your precision metal parts arrive safely and on schedule.

Frequently Asked Questions

Get answers to common questions about our CNC metal machining services and capabilities.

What tolerances can you achieve with CNC metal machining?

What types of metals can you machine?

Do you provide surface treatment services?

What file formats do you accept for CNC machining projects?

Can you handle both prototype and production volumes?

What quality certifications do you maintain?

Get Your CNC Metal Machining Quote Today

Ready to start your precision metal machining project? Contact Rapidaccu for expert consultation and competitive pricing on your CNC metal parts.

Contact Information

Our Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comExperience

15+ years in precision CNC metal machining

Quality Assurance

ISO 9001 certified manufacturing processes

Why Choose Rapidaccu?

- 15+ years of CNC machining expertise

- Advanced 3, 4, and 5-axis CNC equipment

- Tight tolerances up to ±0.005mm

- Comprehensive material selection

- ISO 9001 quality management