What is the Melting Point of Brass?

At Rapidaccu, we specialize in brass manufacturing and understand that this versatile alloy doesn’t have a single melting point—it has a range that varies based on composition.

Understanding Brass Melting Temperatures

Unlike pure metals with precise melting points, brass is an alloy—primarily copper and zinc—with a melting range between 900°C and 940°C (1,650°F to 1,720°F). At Rapidaccu, we work with dozens of brass compositions daily, and each one behaves differently when exposed to heat. This range isn’t a limitation; it’s a feature that allows us to tailor brass properties for specific manufacturing applications.

The specific melting temperature depends on the copper-to-zinc ratio and the presence of other alloying elements like lead, tin, aluminum, or silicon. This variability is precisely why brass is so valuable in manufacturing—we can select compositions that optimize both processing characteristics and final part performance.

Why the Range Matters

Different melting points suit different manufacturing methods

Lower melting temps reduce energy costs in casting

Composition affects strength, corrosion resistance, and machinability

Knowing melting range guides annealing and heat treatment

Why Brass Melting Point Knowledge Matters at Rapidaccu

Whether you’re designing components for marine applications, architectural hardware, electrical connectors, or musical instruments, understanding how brass responds to temperature is fundamental. In this comprehensive guide, we’ll explore how brass’s melting characteristics influence every aspect of manufacturing—from CNC machining where we stay well below melting temperature, to 3D printing where we must precisely control melt pools, to sheet metal forming where thermal properties determine formability, to stamping operations where work hardening and heat generation are constant considerations.

The Variable Melting Range of Brass

Yellow Brass

63% Copper, 37% Zinc

Red Brass

85% Copper, 15% Zinc

Muntz Metal

60% Copper, 40% Zinc

Understanding the Melting Range

At Rapidaccu, we explain to clients that brass doesn’t simply “melt” at one temperature like pure copper (1,085°C) or pure zinc (420°C). Instead, brass exhibits a solidus-liquidus range:

Solidus Temperature

The temperature where melting begins. Below this point, brass is completely solid.

Liquidus Temperature

The temperature where brass becomes completely liquid. Above this, it’s fully molten.

Rapidaccu Insight:

Between solidus and liquidus, brass exists in a “mushy zone” where solid and liquid phases coexist. This characteristic is crucial for casting operations—we superheat brass 50-100°C above liquidus to ensure complete fluidity and proper mold filling. For welding and brazing, we carefully control this transition zone to achieve strong joints without damaging base material.

How Composition Affects Melting Temperature

At Rapidaccu, we’ve processed hundreds of brass compositions, and we’ve learned that even small compositional changes significantly impact melting behavior. Here’s what drives these variations:

Copper Content

Higher copper content = Higher melting point

Alloying Elements

Additional elements modify melting behavior

Lowers melting point slightly, improves machinability (free-cutting brass)

Raises melting point, enhances corrosion resistance (Admiralty brass, Naval brass)

Increases melting point and strength (Aluminum brass)

Slightly lowers melting point, improves casting characteristics

Rapidaccu’s Material Selection Expertise

When clients approach us with a brass component specification, we don’t just consider the final mechanical properties—we analyze how the melting point of different brass compositions will affect manufacturability. A lower melting point brass might be perfect for die casting or investment casting, reducing energy costs and cycle times. A higher melting point red brass might be essential for applications requiring superior corrosion resistance and strength, even though it demands more energy for casting operations. Our metallurgical expertise ensures you get the optimal balance of properties and processability.

Common Brass Alloys and Their Melting Points

At Rapidaccu, we maintain detailed thermal property databases for every brass alloy we process. This comprehensive table reflects our real-world manufacturing experience:

| Alloy Type | UNS Number | Composition | Solidus (°C) | Liquidus (°C) | Key Applications |

|---|---|---|---|---|---|

| Gilding Metal | C21000 | 95Cu-5Zn | 1,030 | 1,075 | Coins, medals, bullet jackets |

| Commercial Bronze | C22000 | 90Cu-10Zn | 1,010 | 1,040 | Weatherstripping, etching |

| Red Brass | C23000 | 85Cu-15Zn | 990 | 1,025 | Plumbing, condenser tubes |

| Cartridge Brass | C26000 | 70Cu-30Zn | 915 | 940 | Ammunition, hardware, springs |

| Yellow Brass | C26800 | 66Cu-34Zn | 900 | 930 | Architectural trim, fasteners |

| Muntz Metal | C28000 | 60Cu-40Zn | 900 | 905 | Marine hardware, heat exchangers |

| Free-Cutting Brass | C36000 | 61Cu-36Zn-3Pb | 885 | 890 | High-speed machining parts |

| Admiralty Brass | C44300 | 71Cu-28Zn-1Sn | 920 | 945 | Marine condenser tubes |

| Naval Brass | C46400 | 60Cu-39Zn-1Sn | 900 | 940 | Marine propeller shafts, valves |

| Aluminum Brass | C68700 | 77Cu-21Zn-2Al | 950 | 1,000 | Marine heat exchangers, power plant condensers |

Important Note from Rapidaccu:

These values are typical ranges. Actual melting behavior can vary ±10-20°C based on specific heat treatment history, grain structure, and minor compositional variations within specification limits. When we design casting or welding processes, we always reference certified mill test reports and conduct thermal analysis testing to ensure optimal parameter selection.

Melting Point’s Role in CNC Machining

Why Melting Point Matters in Machining

At Rapidaccu’s CNC machining centers, we never approach brass’s 900-940°C melting range during cutting operations—but understanding this thermal property is still critical for achieving optimal results.

Brass’s melting point tells us about its thermal conductivity, work hardening characteristics, and how it will respond to machining-induced heat. While cutting generates friction and heat, brass’s moderate thermal conductivity (compared to pure copper) means heat dissipates at a controlled rate—neither too fast (which would concentrate heat in tools) nor too slow (which would cause workpiece thermal expansion).

Rapidaccu’s Machining Advantages:

- Cutting speeds up to 500 SFM for free-cutting brass

- Superior surface finishes (Ra 0.8 µm achievable)

- Extended tool life vs. harder materials

- Tight tolerances: ±0.0005″ standard

Temperature Control

While far below melting point, we monitor cutting zone temperatures. Free-cutting brass (C36000) machines cooler due to lead content, while higher-copper red brass generates slightly more heat but offers superior corrosion resistance.

Tool Selection

Brass’s melting point range guides tool material choice. Carbide tools excel for high-speed operations, while HSS works well for lower speeds. The relatively low melting point (vs. steel) means less tool thermal stress.

Coolant Strategy

Knowledge of thermal properties helps us select appropriate cutting fluids. Light mineral oil works excellent for brass, providing lubrication without excessive cooling that could cause dimensional issues during finishing passes.

Why Choose Rapidaccu for Brass CNC Machining?

Our expertise in brass’s thermal and mechanical properties translates directly to superior machined components. We process all brass alloys from free-cutting C36000 to corrosion-resistant aluminum brass C68700, optimizing parameters for each composition’s unique characteristics.

Capabilities:

- • 3-axis, 4-axis, and 5-axis CNC machining

- • Swiss-style turning for complex geometries

- • Production volumes: 1 to 100,000+ pieces

- • Complex thread forms and fine pitches

Quality Assurance:

- • CMM inspection with GD&T verification

- • Material certification & traceability

- • First article inspection reports

- • ISO 9001:2015 certified facility

Temperature Challenges in Brass 3D Printing

Mastering the Brass Melt Pool

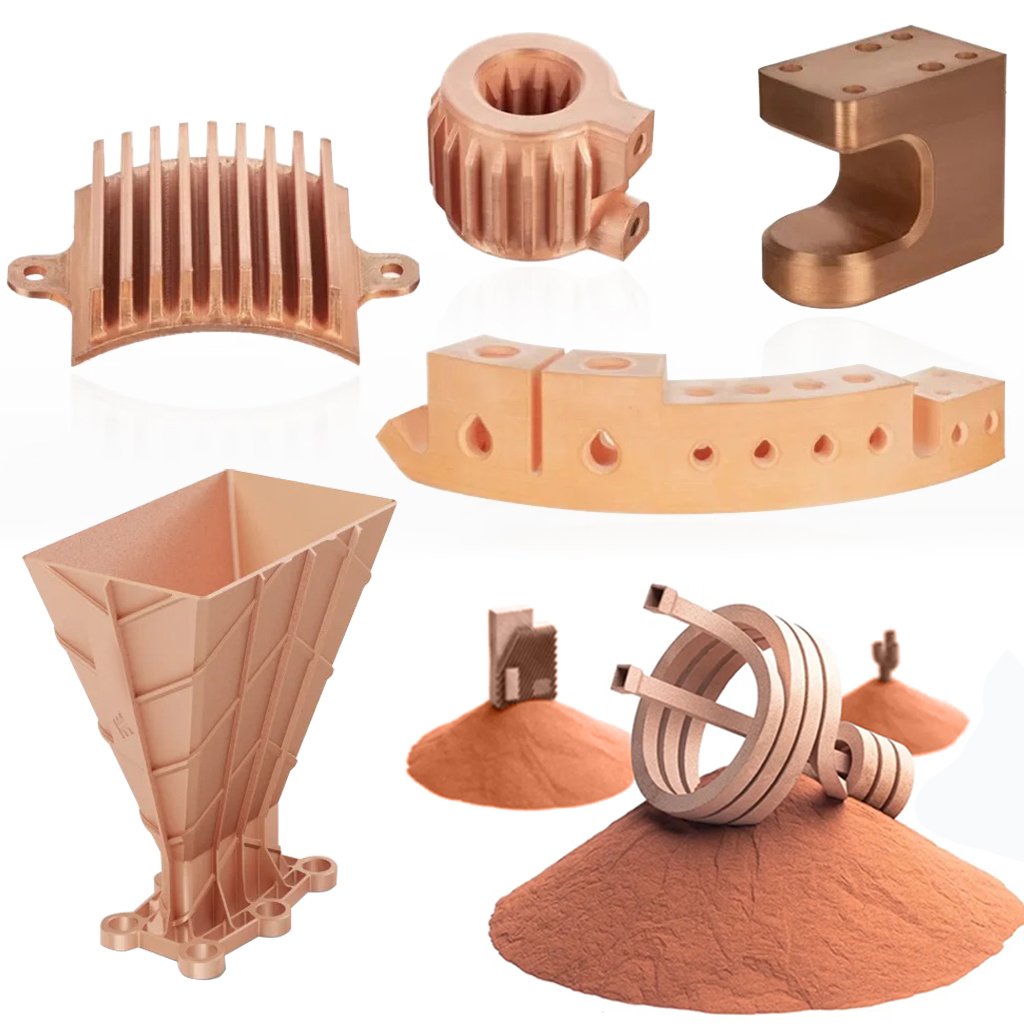

Brass 3D printing at Rapidaccu requires precisely controlling temperatures around the 900-940°C melting range. Unlike CNC machining that stays far below this temperature, additive manufacturing must repeatedly melt and solidify brass powder, layer by layer.

The challenge with brass 3D printing isn’t just reaching melting temperature—it’s managing zinc vaporization. Zinc’s boiling point (907°C) sits right in brass’s melting range, meaning excessive heat causes zinc loss, altering composition and compromising part properties.

Critical Temperature Control

We operate laser power bed fusion systems at carefully calibrated energy densities, superheating powder just 50-100°C above liquidus while minimizing zinc vaporization through rapid scanning and controlled atmospheres.

Rapidaccu’s Brass 3D Printing Solutions

Temperature Management

- High-power fiber lasers: 400-800W delivering precise energy to melt brass powder

- Preheated build platforms: 200°C platform temperature reduces thermal gradients

- Real-time thermal monitoring: Melt pool cameras ensure consistent fusion

- Controlled atmosphere: Argon environment (<100ppm O₂) prevents oxidation

Material Specifications

- CuZn40 powder: 60/40 brass optimized for LPBF, melting range 900-905°C

- Particle size: 15-45µm spherical powder for uniform melting

- Flowability optimization: Powder characteristics tuned for consistent spreading

- Compositional control: Post-print analysis confirms zinc retention

Applications of Brass 3D Printing

Understanding brass melting behavior allows us to produce components impossible with traditional methods:

Musical Instruments

Complex internal acoustics, custom mouthpieces

Fluid Components

Conformal cooling channels, manifolds

Decorative Items

Intricate lattice structures, custom jewelry

Thermal Forming Below Melting Point

Working with Brass Below 900°C

At Rapidaccu’s sheet metal facility, brass’s melting point defines the upper limit of our thermal processing window. Most brass forming occurs at room temperature, but understanding the 900-940°C melting range helps us optimize annealing, stress relief, and hot forming operations.

Brass’s formability improves dramatically at elevated temperatures (but still well below melting). We use this characteristic for complex bending operations, deep draws, and forming operations that would crack or tear at room temperature.

Key Temperature Ranges

Laser Cutting

Localized heating for clean cuts without affecting base material

Bending

Room temp for simple bends, heated for complex geometries

Welding

TIG welding carefully controls heat to avoid zinc vaporization

Annealing

Controlled heating restores ductility for further forming

Rapidaccu Sheet Metal Excellence

Capabilities:

- • Sheet thickness: 0.010″ to 0.187″

- • Precision bending up to 120 tons

- • Laser cutting with nitrogen assist

- • Complex assemblies and welding

Surface Finishing:

- • Polishing to mirror finish

- • Brushed/satin finishes

- • Clear coating for corrosion protection

- • Antiqued or patina finishes

Heat Generation in Stamping Operations

Managing Heat in High-Speed Production

Brass stamping at Rapidaccu operates at room temperature, but the physics of metal forming means we’re constantly managing heat generation. While we never approach the 900°C+ melting range, understanding brass’s thermal properties helps us optimize die design, cycle rates, and material flow.

Rapid deformation during stamping generates heat through plastic work. At production speeds of 200-400 strokes per minute, this cumulative heating can affect dimensional accuracy, surface finish, and part consistency if not properly managed.

Thermal Management Strategy

We monitor strip temperature during production. If brass strip exceeds 60°C, we implement cooling measures to maintain dimensional stability and prevent work hardening issues that could affect subsequent forming stages.

Why Brass Excels in Stamping

Excellent Formability

Lower work hardening rate than steel allows complex geometries in fewer operations. The moderate melting point correlates with easier atom movement during forming.

Good Thermal Conductivity

Heat dissipates from the forming zone quickly, preventing localized softening that could cause tearing or wrinkling in drawn parts.

Visual Appeal

Brass’s golden appearance right out of the die makes it ideal for decorative applications—no secondary finishing needed for many parts.

Rapidaccu Stamping Capabilities

Production Range:

- • Material thickness: 0.008″ to 0.187″

- • Part sizes up to 16″ x 20″

- • Volumes: 5,000 to 10,000,000+ per year

- • Progressive dies up to 20 stations

Brass Alloys:

- • C26000 (Cartridge brass) – General purpose

- • C36000 (Free-cutting brass) – High-speed ops

- • C44300 (Admiralty brass) – Marine applications

- • Custom tempers (H01, H02, H04, etc.)

Our understanding of how brass behaves under forming stress—informed by knowledge of its melting point and thermal characteristics—allows us to produce components with exceptional consistency, tighter tolerances, and superior surface finishes.

Request Brass Stamping Quote →Welding and Brazing Near Melting Point

Welding and brazing operations bring us closest to brass’s 900-940°C melting range in our everyday manufacturing. At Rapidaccu, we’ve mastered these joining processes by understanding precisely how to control temperature in the critical zone near brass’s melting point.

TIG Welding Brass

Gas Tungsten Arc Welding (GTAW/TIG) is our primary method for welding brass. We must heat brass above its 900°C+ melting point locally while managing two critical challenges:

Zinc boils at 907°C—right in brass’s melting range. We carefully control heat input to minimize zinc loss which weakens joints.

Brass’s good thermal conductivity pulls heat away quickly. We often preheat workpieces to 200-300°C for thicker sections.

Our Welding Parameters:

- • Silicon bronze filler (ERCuSi-A) for strength

- • Argon shielding gas at 15-20 CFH

- • Fast travel speed to limit heat input

- • Weave patterns for wider heat distribution

Brazing Brass Assemblies

Brazing offers an alternative where we melt filler metal below brass’s melting point. This is ideal for joining brass to dissimilar metals or creating joints in thin-wall assemblies:

Below brass melting point. Creates strong, ductile joints without melting base metal.

Uses brass filler rods with slightly lower melting point than base metal.

Advantages of Brazing:

- • Base metal doesn’t melt—no composition change

- • Lower heat input reduces distortion

- • Can join dissimilar metals effectively

- • Excellent for complex assemblies

Why Melting Point Knowledge Ensures Superior Joints

At Rapidaccu, our welding and brazing engineers don’t just know that brass melts around 900-940°C—we understand how different compositions respond at these critical temperatures. This expertise allows us to:

Precise Parameter Selection

Optimize current, travel speed, and filler selection for each brass alloy

Defect Prevention

Avoid porosity from zinc vaporization and hot cracking from improper cooling

Quality Assurance

X-ray and leak testing ensures joints meet stringent requirements