Custom Inconel Parts Manufacturing

We have 15 years of experience in manufacturing Inconel and other specialty alloy materials.

We are skilled in processing all Inconel grade materials

Specialized expertise in multiple Inconel alloys for various applications

Inconel 718 Superalloy

High-strength, corrosion-resistant nickel-chromium alloy for extreme temperatures up to 1300°F (700°C).

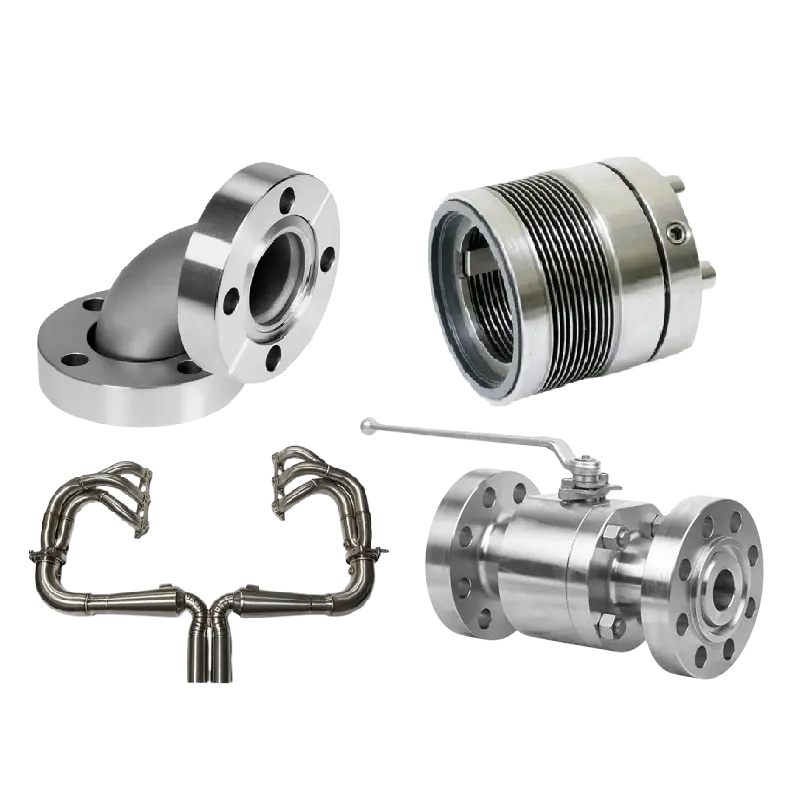

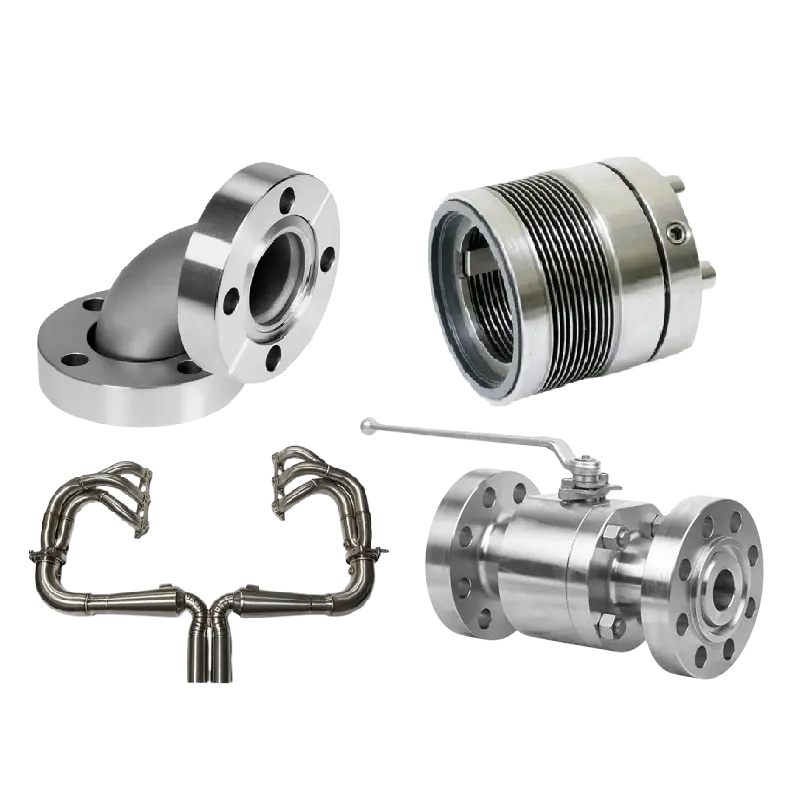

Common Parts We Manufacture:

- Inconel 718 Turbine Blades

- Inconel 718 Fasteners

- Inconel 718 Springs

- Forged Inconel 718 Rotors

- Rocket Engine Components

- Aerospace Structural Parts

- Gas Turbine Components

- High-Pressure Shafts

Inconel 625 Superalloy

Excellent resistance to oxidation and corrosion, ideal for seawater and high-temperature applications.

Common Parts We Manufacture:

- Custom Inconel 625 Springs

- Inconel 625 Fasteners

- Aerospace Shafts

- Marine Components

- Chemical Processing Equipment

- Exhaust Systems

- Heat Exchangers

- Valve Components

Inconel 600 Alloy

Nickel-chromium alloy with excellent resistance to high-temperature oxidation and corrosive environments.

Common Parts We Manufacture:

- Inconel 600 Fittings

- Inconel 600 Flanges

- Furnace Components

- Heat Treating Equipment

- Chemical Processing Parts

- Turbine Blades

- Thermocouple Components

- Nuclear Reactor Parts

Inconel X-750 Superalloy

Age-hardenable nickel-chromium alloy with excellent creep and rupture strength at temperatures up to 1500°F (816°C).

Common Parts We Manufacture:

- Inconel X-750 Springs

- Turbine Seals

- Rocket Engine Parts

- Gas Turbine Blades

- Fasteners and Bolts

- Nuclear Reactor Components

- Aircraft Engine Parts

- High-Temperature Springs

Incoloy 825 Nickel Alloy

Nickel-iron-chromium alloy with excellent resistance to corrosion in oxidizing and reducing environments.

Common Parts We Manufacture:

- Chemical Processing Equipment

- Pollution Control Systems

- Oil and Gas Components

- Acid Production Equipment

- Flanges and Fittings

- Piping Systems

- Heat Exchangers

- Tank Components

Additional Inconel & Nickel Alloys Comparison

We manufacture precision parts from a wide range of specialty nickel-based superalloys. Compare key properties and applications below:

| Alloy Grade | Key Elements | Density (g/cm³) | Melting Point (°C) | Key Properties | Typical Applications |

|---|---|---|---|---|---|

| Inconel 600 | Ni-Cr-Fe | 8.47 | 1413 | Excellent oxidation resistance, high-temperature strength, good fabricability | Furnace components, heat exchangers, chemical processing |

| Inconel 601 | Ni-Cr-Al-Fe | 8.11 | 1411 | Superior oxidation resistance, thermal fatigue resistance, carburization resistance | Thermal processing equipment, industrial furnaces, petrochemical |

| Inconel 617 | Ni-Cr-Co-Mo | 8.36 | 1332 | Excellent creep strength, outstanding metallurgical stability at high temperatures | Gas turbines, combustion systems, heat-treating equipment |

| Inconel 690 | Ni-Cr-Fe | 8.19 | 1343 | Exceptional corrosion resistance in high-purity water, stress corrosion cracking resistance | Nuclear steam generators, pressurized water reactors |

| Inconel 800/800H/800HT | Ni-Fe-Cr | 7.94 | 1357 | Resistance to oxidation and carburization, good creep resistance | Heat exchangers, furnace components, chemical processing |

| Hastelloy C-276 | Ni-Mo-Cr-W | 8.89 | 1370 | Outstanding resistance to pitting and stress corrosion cracking, versatile corrosion resistance | Chemical processing, pollution control, waste treatment |

| Hastelloy X | Ni-Cr-Fe-Mo | 8.22 | 1260 | Excellent high-temperature strength, oxidation resistance up to 1200°C | Gas turbines, industrial furnaces, aerospace applications |

| Incoloy 825 | Ni-Fe-Cr-Mo-Cu | 8.14 | 1400 | Excellent resistance to acids, outstanding stress corrosion cracking resistance | Chemical processing, oil & gas, pollution control |

| Monel 400 | Ni-Cu | 8.80 | 1350 | Excellent corrosion resistance to seawater and acids, good mechanical properties | Marine engineering, chemical processing, oil refining |

| Nimonic 90 | Ni-Cr-Co-Ti-Al | 8.18 | 1399 | High creep resistance, excellent oxidation resistance, age-hardenable | Gas turbines, jet engines, high-temperature fasteners |

We Also Machine Other Difficult Materials

Beyond Inconel, we specialize in precision machining of various high-performance alloys

Our Inconel Manufacturing Capabilities

Advanced manufacturing processes for complex Inconel components

CNC Machining

- 3/4/5-axis CNC milling

- CNC turning up to Ø500mm

- Tolerance: ±0.005mm

- Surface finish: Ra 0.4μm

3D Printing (SLM/DMLS)

- Metal additive manufacturing

- Build volume: 500×500×500mm

- Layer thickness: 20-100μm

- Complex geometries

Sheet Metal Fabrication

- Laser cutting up to 25mm

- Bending & forming

- Welding & assembly

- Thickness: 0.5-25mm

Metal Stamping

- Progressive stamping

- Up to 400 tons press

- High-volume production

- Complex geometries

Forging

- Hot & cold forging

- Weight: 0.1-100kg

- Superior strength

- Grain flow optimization

Die Casting

- High-pressure die casting

- Complex geometries

- Excellent surface finish

- High production volume

Need Other Inconel Processes?

We also offer: Welding & Joining, EDM, Wire Cutting, Grinding, Polishing, Heat Treatment, and more

Inconel Surface Finishing Options

Professional surface treatments for enhanced performance and aesthetics

Anodizing

Enhanced corrosion resistance and surface hardness

Electropolishing

Mirror-like finish with improved cleanability

Passivation

Chemical treatment for corrosion protection

Coating

Protective coatings for extreme environments

Bead Blasting

Uniform matte surface finish

Polishing

High-gloss mirror finish

Heat Treatment

Stress relief and hardening processes

Need Other Finishes?

We offer additional surface treatments

Industry Solutions

Specialized Inconel parts for diverse industries

Aerospace Industry

High-performance Inconel components for extreme aerospace applications, from jet engines to rocket propulsion systems.

Critical Components:

- Turbine Blades & Vanes

- Exhaust Systems

- Rocket Engine Nozzles

- Combustion Chambers

- Aircraft Engine Fasteners

- Heat Shields

- Fuel System Components

- Structural Brackets

Automotive Industry

High-temperature resistant Inconel parts for performance and racing applications.

Critical Components:

- Exhaust Valves

- Turbocharger Components

- Exhaust Manifolds

- Racing Engine Parts

- High-Performance Springs

- Exhaust Systems

- Valve Seats

- Turbo Housings

Oil & Gas

High-performance components engineered for extreme pressure, corrosive environments, and offshore drilling operations.

Critical Components:

- Ball Valves & Gate Valves

- Wellhead Components

- Downhole Tools

- Subsea Equipment

- Pump Components

- Pipe Fittings & Flanges

- Pressure Control Equipment

- Heat Exchanger Parts

Chemical Processing

Chemical-resistant Inconel parts for harsh processing environments.

Critical Components:

- Reactor Vessels

- Process Piping

- Valve Components

- Pump Parts

- Heat Exchangers

- Mixing Equipment

- Flanges & Fittings

- Tank Components

Medical & Pharmaceutical

Biocompatible Inconel components for medical devices and pharmaceutical equipment.

Critical Components:

- Surgical Instruments

- Implantable Devices

- Sterilization Equipment

- Pharmaceutical Processing

- Laboratory Equipment

- Medical Tool Parts

- Autoclave Components

- Precision Springs

Marine & Offshore

Seawater-resistant Inconel parts for marine and offshore applications.

Critical Components:

- Propulsion System Parts

- Seawater Valves

- Marine Fasteners

- Offshore Platform Components

- Pump Components

- Piping Systems

- Heat Exchangers

- Corrosion-Resistant Fittings

Why Choose Us

Your trusted partner for precision Inconel manufacturing

Difficult Materials Expertise

We are renowned for our successful processing of metals that other manufacturers are unwilling to handle, allowing our clients to confidently use new materials in their designs.

Advanced Manufacturing Technology

State-of-the-art 5-axis CNC machines, metal 3D printing systems, and precision CMM measurement equipment ensure superior quality and complex geometries.

Complete Quality Documentation

Full material traceability, NDT inspection reports, dimensional inspection certificates, and mill test reports provided with every shipment.

Engineering Support & DFM

Experienced engineers provide Design for Manufacturing analysis, material selection guidance, and technical support throughout your project lifecycle.

Flexible Production Capacity

From single prototypes to high-volume production runs, we scale our services to meet your exact requirements with consistent quality.

ISO Certified & NDA Protected

ISO 9001:2015 certified quality management system with strict confidentiality protection for your intellectual property and designs.

Custom Inconel Parts Success Cases

Real projects delivered for leading companies worldwide

Frequently Asked Questions

Common questions about Inconel parts manufacturing

What Inconel grades can you machine?

We specialize in machining all major Inconel grades including 718, 625, 600, X-750, 800, 800H, 800HT, 690, and 601. We also work with Incoloy 825 and other nickel-based superalloys.

What is your minimum order quantity?

We accept orders from single prototypes to high-volume production runs. There is no strict minimum order quantity – we’re flexible to meet your specific needs.

What tolerances can you achieve?

Our precision CNC equipment can achieve tolerances as tight as ±0.005mm (±0.0002″). For standard parts, we typically work to ±0.02mm tolerances. Surface finish down to Ra 0.4μm is achievable.

Do you provide material certifications?

Yes, we provide complete material traceability and certifications including mill certificates, material test reports, and third-party inspection reports as required.

Can you handle complex geometries?

Absolutely. Our 5-axis CNC machines, EDM, and wire cutting capabilities enable us to produce highly complex parts with intricate features, undercuts, and tight tolerances.

What is the typical lead time?

Lead times vary based on complexity and quantity. Typically: Prototypes: 1-2 weeks, Small batches (10-100 pcs): 2-4 weeks, Production runs: 4-8 weeks. Rush services are available.

Do you sign NDAs?

Yes, we understand the importance of protecting your intellectual property. We’re happy to sign non-disclosure agreements before discussing your project details.

What quality certifications do you have?

We are ISO 9001:2015 certified and follow strict quality management systems. We can also provide AS9100 compliant manufacturing for aerospace customers.

Can you assist with design optimization?

Yes, our engineering team provides free DFM (Design for Manufacturing) analysis to optimize your designs for better manufacturability, cost efficiency, and performance.

Do you offer factory visits?

Yes, we welcome customers to visit our facility in Shenzhen, China. Factory tours can be arranged to see our equipment, quality control processes, and meet our team.

Get in Touch

Ready to start your Inconel parts project? Contact us today

Our Location

Rongli Industrial Park, Dalang

Longhua District, Shenzhen, China

Phone Numbers

Email Us

Experience

15 years of precision manufacturing excellence

Quality Assurance

ISO 9001:2015 certified quality management system