- Home ›

- Plastic Machining ›

- Polypropylene Machining

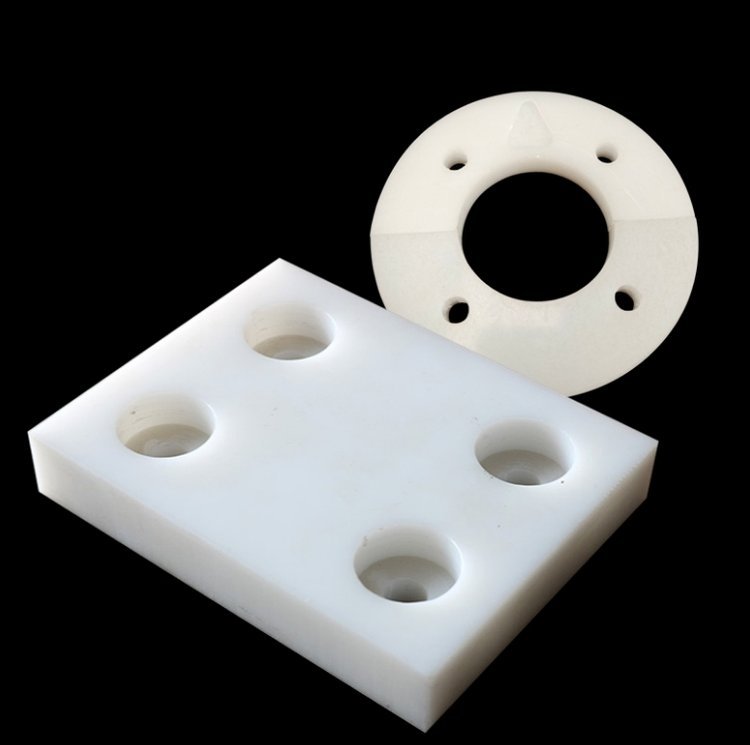

Polypropylene Machining Services

High-quality custom polypropylene parts from China’s experienced manufacturer

Understanding Polypropylene Material

What is Polypropylene?

Polypropylene (PP) is a versatile thermoplastic polymer known for its excellent chemical resistance, low density, and outstanding fatigue resistance. This cost-effective material offers a unique combination of properties making it ideal for a wide range of applications.

With excellent resistance to acids, alkalis, and organic solvents, PP maintains its integrity in harsh chemical environments while remaining lightweight and durable.

Key Polypropylene Advantages

Excellent Chemical Resistance

Resists most acids, alkalis, and organic solvents

High Fatigue Resistance

Withstands repeated flexing and stress cycles

Lightweight Material

Low density for weight-sensitive applications

Cost-Effective Solution

Economical material with excellent properties

Polypropylene Manufacturing Technologies

Complete PP processing solutions for diverse applications

CNC Machining Polypropylene

Precision CNC milling and turning for custom polypropylene parts with excellent accuracy and surface quality.

Polypropylene 3D Printing

Advanced additive manufacturing for rapid prototyping and production of complex PP geometries.

Polypropylene Injection Molding

High-volume injection molding for mass production of PP parts with consistent quality.

Polypropylene Material Properties

Chemical Resistance

Outstanding resistance to acids, alkalis, and most organic solvents for chemical handling applications.

Fatigue Resistance

Exceptional resistance to repeated flexing and stress cycles making it ideal for living hinges.

Lightweight

Low density material providing excellent strength-to-weight ratio for efficient designs.

Moisture Resistant

Virtually no moisture absorption ensuring dimensional stability in humid environments.

Electrical Insulation

Excellent dielectric properties for electrical and electronic component applications.

Cost-Effective

Economical material offering excellent performance at competitive pricing.

Recyclable

Fully recyclable material supporting sustainable manufacturing practices.

Food Grade Available

FDA approved grades available for food contact and packaging applications.

Temperature Range

Performs well from -20°C to 100°C for various temperature applications.

Our Polypropylene Machining Capabilities

Precision CNC Milling

Multi-axis CNC milling for complex polypropylene parts with tight tolerances and excellent surface finishes.

CNC Turning Operations

High-precision turning for cylindrical PP components including bushings and rotational parts.

3D Printing Services

Advanced additive manufacturing for rapid prototyping and complex polypropylene geometries.

Quality Inspection

Comprehensive dimensional verification and quality testing with advanced measurement equipment.

Surface Finishing

Various finishing options including polishing and texturing to achieve desired characteristics.

Documentation

Complete material certifications and inspection reports for your requirements.

Industries & Applications

Packaging Industry

Containers, closures, caps, bottles, and flexible packaging materials for various products.

Automotive

Interior trim, battery cases, bumper components, and under-hood applications.

Chemical Processing

Tanks, pipes, valves, fittings, and chemical handling equipment.

Medical Devices

Syringes, medical packaging, diagnostic equipment housings, and laboratory ware.

Consumer Products

Household items, furniture components, toys, and appliance parts.

Textiles

Fibers for ropes, carpets, upholstery, and non-woven fabrics.

Why Choose Rapidaccu for Polypropylene Machining?

15 Years Experience

Extensive expertise in polypropylene parts manufacturing for global markets.

Advanced Technology

State-of-the-art CNC machines and 3D printing equipment.

ISO Certified Quality

Rigorous quality management systems ensuring excellence.

Competitive Pricing

Cost-effective manufacturing solutions for international customers.

Global Shipping

Reliable worldwide delivery with proper documentation.

Technical Support

Expert engineering team providing design and manufacturing guidance.

Frequently Asked Questions

What is the difference between polypropylene and polyethylene?

Can polypropylene be used for food contact?

What tolerances can you achieve with polypropylene machining?

Is polypropylene suitable for outdoor applications?

Can polypropylene be welded or bonded?

What colors are available for polypropylene?

Request Your Polypropylene Machining Quote

Partner with China’s trusted PP parts manufacturer

Rapidaccu Manufacturing

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comExperience

15 Years in Polypropylene Parts Manufacturing

Our Promise

- ISO Certified Quality

- Worldwide Shipping

- Technical Support

- Competitive Pricing