- Home ›

- Shipbuilding & Maritime Parts CNC Machining

Shipbuilding & Maritime Parts CNC Machining

Rapidaccu manufactures precision CNC machined components for shipbuilding and maritime industries. With 15 years of experience, we produce ship machinery parts, marine equipment, propulsion components, and custom maritime hardware with exceptional durability.

Request QuoteMaritime CNC Machining Services

Robust components for marine environments and shipbuilding applications

Ship Machinery

Engine components, propulsion parts, and marine machinery components

Marine Hardware

Custom fittings, brackets, mounting hardware, and structural components

Propulsion Systems

Shaft components, couplings, and transmission parts for marine propulsion

Boat Components

Precision parts for boats, yachts, and small vessel manufacturing

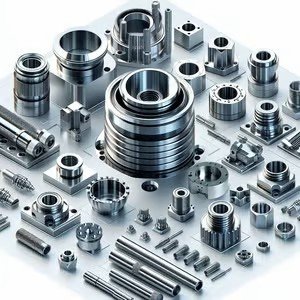

Marine & Shipbuilding Components

CNC Machined Marine Parts

Aluminum and metal components

Shipbuilding Components

Precision and durability

Maritime Equipment Parts

CNC milling and machining

3-Axis CNC Parts

Brass, stainless steel, copper

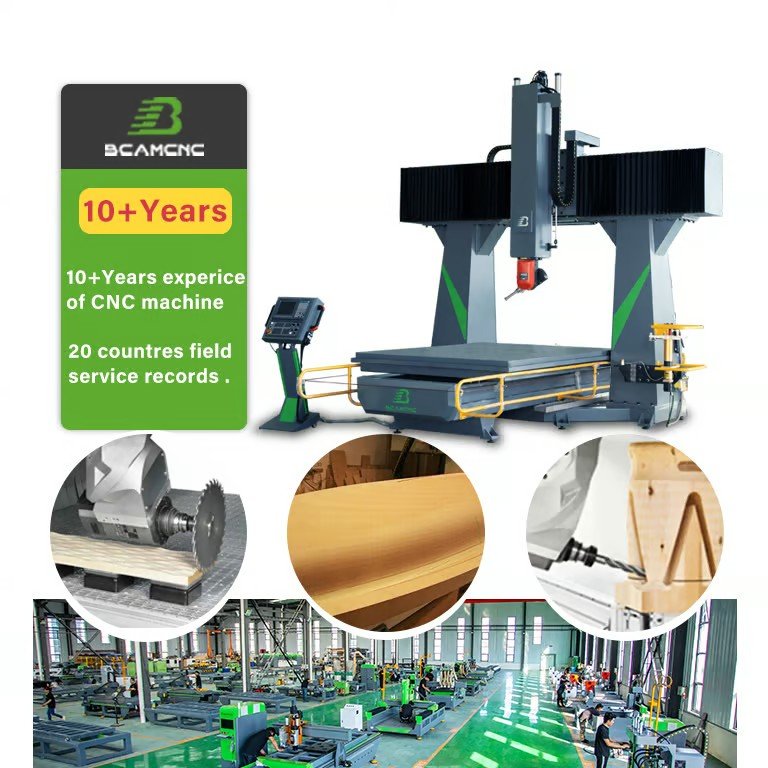

Ship Building Machinery

Precision manufacturing

Boat Mold 5-Axis CNC

Advanced machining precision

Marine Industry Expertise

Corrosion Resistance

Marine-grade materials and protective coatings designed to withstand harsh saltwater environments and extreme weather conditions

Heavy-Duty Construction

Robust components engineered for maritime applications requiring exceptional strength and durability under demanding loads

Large Part Capability

Advanced machinery capable of handling large-scale maritime components for shipbuilding and marine equipment manufacturing

Shipbuilding Manufacturing Excellence

Rapidaccu supports the maritime industry with precision machined components that meet the demanding requirements of shipbuilding and marine applications.

Marine-Grade Materials

Stainless steel 316L, bronze, brass, and corrosion-resistant alloys

Protective Coatings

Specialized finishes for saltwater and UV protection

Large Capacity Equipment

CNC machines for substantial maritime components

Maritime Applications

Components for various maritime and shipbuilding sectors

Commercial Ships

Cargo vessels and transport ships

Naval Vessels

Military and defense marine equipment

Yachts & Boats

Recreational marine craft components

Offshore Platforms

Oil, gas, and marine infrastructure

Shipbuilding CNC Machining FAQs

What maritime parts do you manufacture?

What materials are suitable for marine environments?

Can you machine large shipbuilding parts?

Do you provide corrosion protection treatments?

Can you work with maritime industry certifications?

What lead times for maritime components?

Request Maritime Parts Quote

Rapidaccu Maritime Manufacturing

Factory Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comMaritime Experience

15 Years in CNC Machining Manufacturing

Maritime Manufacturing Benefits

- Marine-Grade Materials Expertise

- Corrosion Protection Treatments

- Large Part Machining Capability

- International Shipping Experience