Die-Cast Heat Sink

Rapidaccu specializes in precision aluminum die-cast heat sinks that deliver exceptional thermal management for demanding applications. Our advanced die casting technology enables complex geometries, superior heat dissipation, and cost-effective mass production.

Die Casting Process Advantages

Our die casting technology combines precision engineering with efficient production capabilities

Complex Shapes

Die casting allows intricate designs including undercuts, thin walls, and integrated features that would be impossible or costly with other manufacturing methods.

Superior Thermal Performance

Utilizing high-conductivity aluminum alloys (A380, ADC12) with thermal conductivity up to 96 W/mK for efficient heat transfer and optimal cooling performance.

Cost Efficiency

Reduced machining operations, minimal material waste, and rapid production cycles make die casting ideal for medium to high-volume manufacturing.

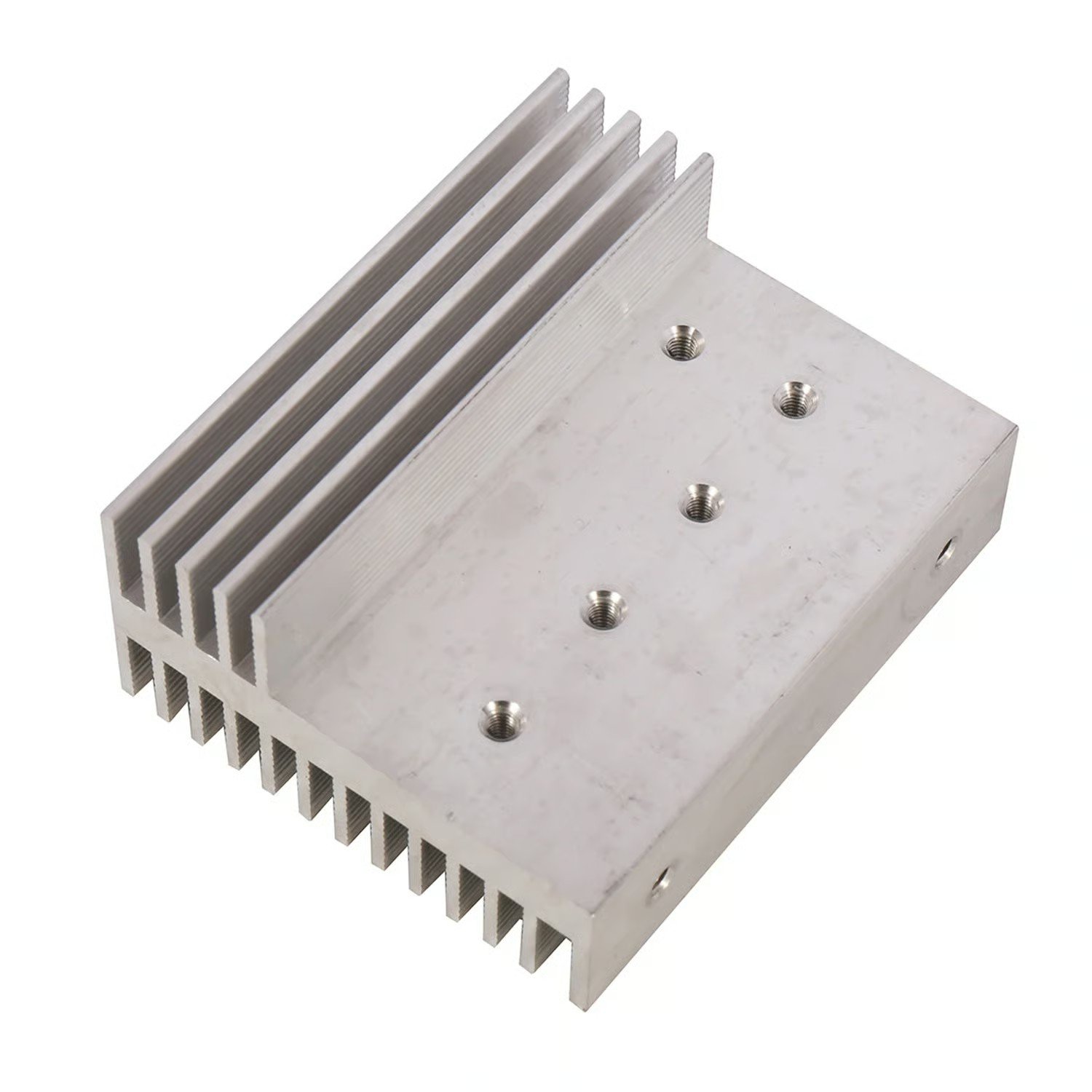

Product Gallery

Precision-engineered die-cast heat sinks for diverse applications

Technical Specifications

Detailed specifications for our die-cast heat sinks

| Material | Aluminum Alloy A380, ADC12 |

| Thermal Conductivity | 96-113 W/mK |

| Tolerance | ±0.1mm – ±0.2mm |

| Surface Finish | As-cast, Machined, Anodized, Powder Coated |

| Wall Thickness | 1.5mm – 6mm |

| Weight Range | 50g – 5kg |

Key Features

High Production Efficiency

Rapid cycle times enable cost-effective mass production with consistent quality

Excellent Surface Quality

Smooth as-cast surfaces reduce or eliminate secondary finishing operations

Design Flexibility

Create integrated mounting features, complex fin arrays, and custom geometries

Material Efficiency

Near-net-shape manufacturing minimizes waste and reduces overall costs

Industry Applications

Die-cast heat sinks serve critical thermal management needs across industries

LED Lighting

Automotive

Electronics

Telecom

Power Electronics

Industrial

Why Choose Rapidaccu?

With 15 years of CNC machining and thermal management expertise, Rapidaccu delivers precision die-cast heat sinks that meet the most demanding specifications.

ISO 9001:2015 Certified

Quality management systems ensuring consistent excellence in every product

Advanced Manufacturing

State-of-the-art die casting equipment and precision CNC machining capabilities

Expert Engineering Support

Collaborative design optimization for maximum thermal performance

Global Export Experience

Reliable international shipping and comprehensive export documentation

Frequently Asked Questions

Common questions about die-cast heat sinks

What are the advantages of die-cast heat sinks over extruded types?

What aluminum alloys are used for die-cast heat sinks?

What is the minimum order quantity for die-cast heat sinks?

Can die-cast heat sinks be customized with specific colors?

How does thermal performance compare to other heat sink types?

Do you provide thermal simulation and design assistance?

Get Your Custom Die-Cast Heat Sink Quote

Contact Rapidaccu today to discuss your thermal management requirements. Our team is ready to provide expert guidance and competitive pricing.

Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Experience

15+ Years in CNC Machining & Thermal Solutions