- Home ›

- Medical Devices Parts CNC Machining

Medical Devices Parts CNC Machining

Rapidaccu specializes in high-precision CNC machining for medical device components. With 15 years of experience, we deliver surgical instruments, implants, and medical equipment parts meeting stringent quality standards.

Get a QuoteMedical-Grade CNC Machining Services

Precision manufacturing for critical medical applications

Surgical Instruments

Stainless steel surgical tools with precision edges and finishes

Orthopedic Implants

Biocompatible titanium and stainless steel implant components

Diagnostic Equipment

Precision parts for medical diagnostic and imaging devices

Medical Enclosures

Custom housings for medical devices and equipment

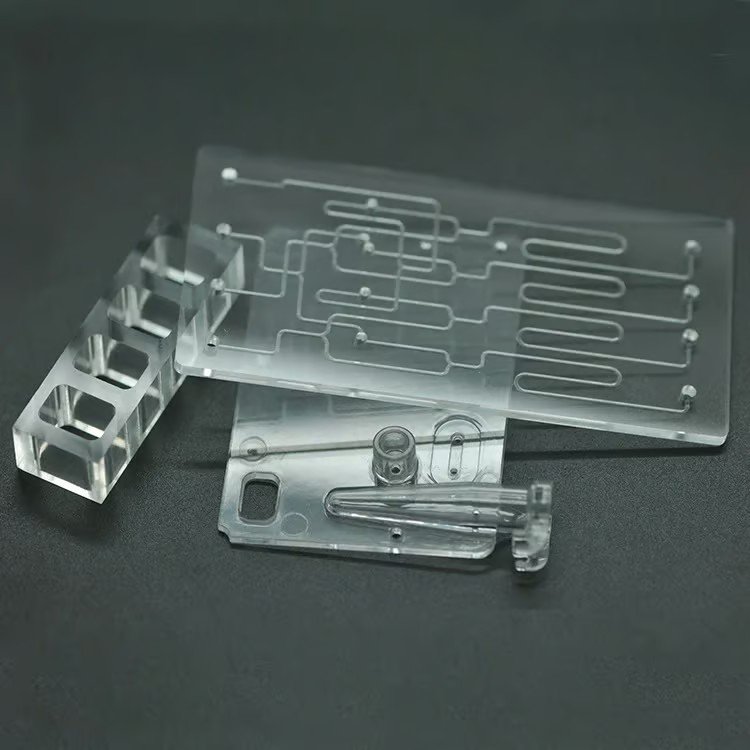

Medical Parts Manufacturing Gallery

Surgical Implant Components

High Tolerance Components

Medical Equipment Parts

Orthopedic Bone Studs

Medical Device Enclosures

Microfluidic Chip Parts

Certified Medical Manufacturing Excellence

Quality Standards Compliance

Our manufacturing processes meet international medical device quality standards and regulations.

Biocompatible Materials

We work with medical-grade stainless steel, titanium, and FDA-approved plastics.

Advanced Inspection

CMM inspection, surface roughness testing, and comprehensive documentation.

Expert Engineering Support

Technical consultation for design optimization and manufacturability.

Medical-Grade Materials We Work With

Biocompatible and sterilization-compatible materials

Stainless Steel

- 316L Medical Grade

- Corrosion Resistant

- Autoclave Safe

Titanium Alloys

- Ti-6Al-4V ELI

- Biocompatible

- Lightweight

Medical Plastics

- PEEK, UHMWPE

- FDA Approved

- Chemical Resistant

Medical Device Manufacturing FAQs

What certifications do you have for medical manufacturing?

Can you machine FDA-approved materials?

What tolerances can you achieve for surgical instruments?

Do you provide surface finishing for medical parts?

How do you ensure cleanliness for medical components?

Can you handle prototypes for new medical devices?

Request Medical Parts Manufacturing Quote

Rapidaccu Medical Manufacturing

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comIndustry Experience

15 Years in Precision CNC Machining

Medical Manufacturing Advantages

- ISO Certified Facility

- Medical-Grade Materials

- Full Documentation & Traceability

- Confidentiality Guaranteed