- Home›

- CNC Metal Machining›

- Custom CNC Machining Aluminum Parts

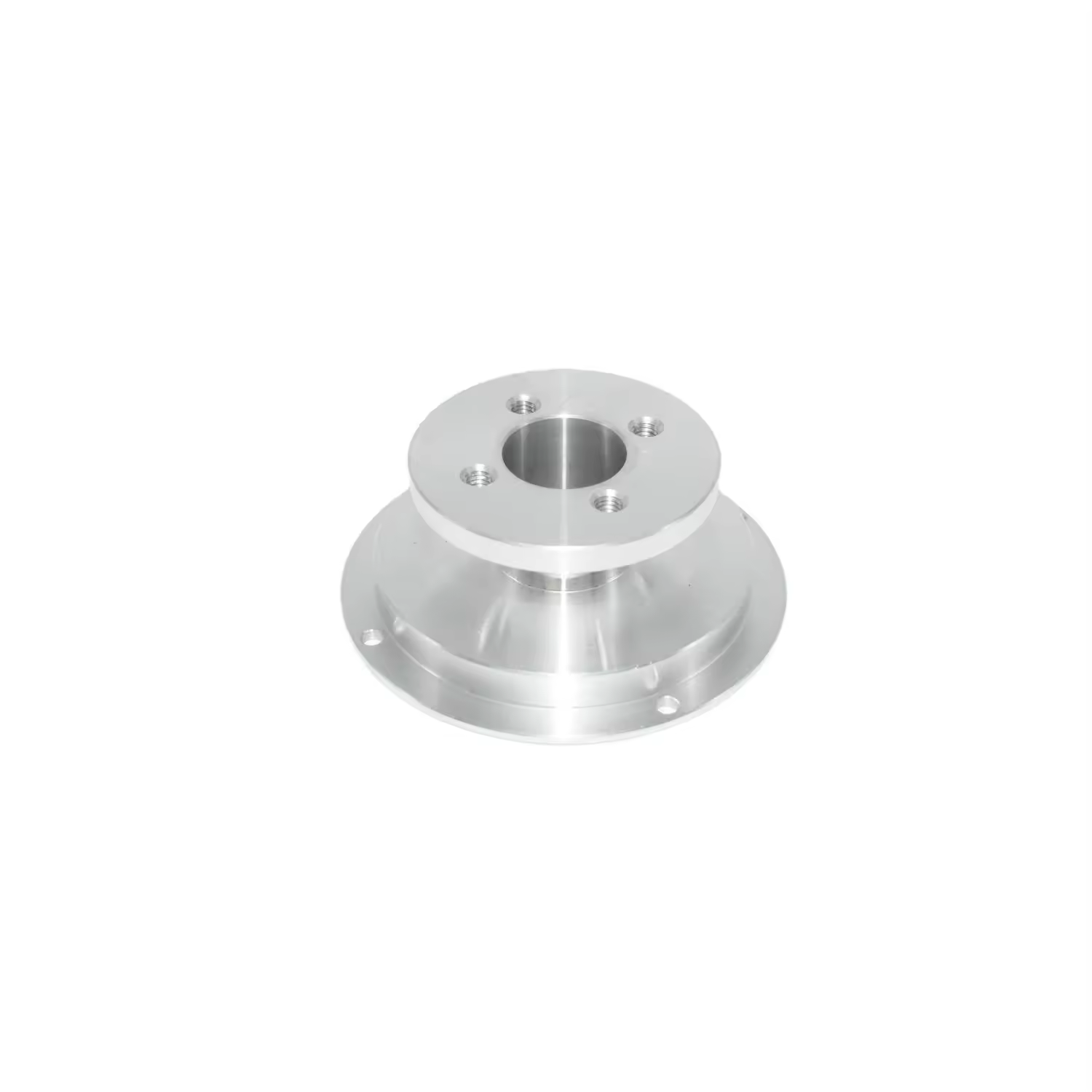

Custom CNC Machining Aluminum Parts

Professional precision aluminum machining services with exceptional strength-to-weight ratio. 15 years of expertise delivering high-quality custom aluminum components for aerospace, automotive, and industrial applications.

Why Choose Rapidaccu for Aluminum CNC Machining

With 15 years of precision manufacturing experience, Rapidaccu delivers exceptional custom aluminum parts that meet the highest industry standards.

Advanced CNC Technology

State-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers capable of producing complex aluminum components with tight tolerances up to ±0.005mm.

ISO 9001 Certified

Our quality management system ensures consistent quality and traceability throughout the manufacturing process, meeting international standards.

Fast Turnaround

Prototype parts in 3-5 days, production runs in 7-15 days. Located in Shenzhen’s manufacturing hub for efficient global shipping.

Precision Inspection

CMM inspection, surface roughness testing, and dimensional verification ensure every part meets your exact specifications.

Material Expertise

Extensive experience with all aluminum grades including 6061, 7075, 2024, 5052, and specialty alloys for specific applications.

Surface Finishing

Complete finishing services including anodizing, powder coating, sandblasting, and custom surface treatments.

Aluminum Material Properties

Aluminum offers exceptional advantages for precision machining applications

Excellent Strength-to-Weight Ratio

Aluminum provides high strength while being approximately one-third the weight of steel, making it ideal for aerospace and automotive applications.

Natural Corrosion Resistance

Forms a protective oxide layer that prevents corrosion, extending component life in harsh environments without additional coatings.

Superior Machinability

Excellent machinability allows for high-speed cutting, complex geometries, and superior surface finishes with extended tool life.

Thermal Conductivity

High thermal conductivity makes aluminum ideal for heat sinks, electronic housings, and heat exchange applications.

ASTM Aluminum Grades Specifications

Comprehensive comparison of aluminum alloys for precision machining applications

| Grade | Main Alloying Elements | Tensile Strength (MPa) | Yield Strength (MPa) | Machinability | Typical Applications | Cost Level |

|---|---|---|---|---|---|---|

| 6061-T6 | Mg, Si | 310 | 276 | Excellent | General purpose, structural, automotive | Moderate |

| 7075-T6 | Zn, Mg, Cu | 572 | 503 | Good | Aerospace, high-stress components | High |

| 2024-T3 | Cu, Mg | 483 | 345 | Good | Aircraft fittings, fatigue-critical parts | High |

| 5052-H32 | Mg | 228 | 193 | Good | Marine, fuel tanks, sheet metal work | Moderate |

| 6063-T6 | Mg, Si | 241 | 214 | Excellent | Extrusions, architectural, railings | Low |

| 7050-T7651 | Zn, Mg, Cu, Zr | 524 | 490 | Good | Aircraft structures, thick sections | High |

| MIC-6 | Al Cast Alloy | 145 | 105 | Excellent | Tooling plates, jigs, fixtures | High |

Applications Across Industries

Our precision aluminum components serve diverse industrial sectors

Aerospace

Aircraft structural components, landing gear parts, brackets, and housings requiring high strength-to-weight ratios and fatigue resistance.

- • Structural brackets

- • Control housings

- • Landing gear components

Automotive

Engine components, suspension parts, brake systems, and lightweight structural elements for improved fuel efficiency.

- • Engine blocks

- • Suspension components

- • Brake calipers

Electronics

Heat sinks, electronic housings, enclosures, and thermal management components leveraging aluminum’s conductivity.

- • Heat sinks

- • Equipment housings

- • Thermal interfaces

Medical

Surgical instruments, diagnostic equipment housings, and biocompatible components meeting medical industry standards.

- • Surgical instruments

- • Equipment housings

- • Diagnostic components

Marine

Corrosion-resistant components for marine environments including fittings, propellers, and structural elements.

- • Marine fittings

- • Propeller components

- • Deck hardware

Industrial

Machinery components, automation parts, pneumatic and hydraulic system elements for industrial applications.

- • Machinery parts

- • Automation components

- • Hydraulic fittings

Advanced Manufacturing Capabilities

Rapidaccu’s state-of-the-art facility in Shenzhen combines advanced CNC technology with skilled craftsmanship to deliver precision aluminum components.

3-axis, 4-axis, and 5-axis CNC machining centers

Tolerances as tight as ±0.005mm

Parts up to 2000mm x 800mm x 1000mm

24/7 production capability

Quality Assurance & Certifications

Comprehensive quality control ensures every aluminum part meets your exact specifications

ISO 9001:2015

Quality management system certification

CMM Inspection

Coordinate measuring machine verification

Material Certs

Complete material traceability documentation

First Article

Complete first article inspection reports

Frequently Asked Questions

Common questions about our aluminum CNC machining services

What aluminum grades do you machine?

What tolerances can you achieve with aluminum parts?

What surface finishes are available for aluminum parts?

What is your typical lead time for aluminum parts?

Do you provide material certificates for aluminum parts?

What file formats do you accept for aluminum part designs?

Get Your Aluminum Parts Quote Today

Ready to start your aluminum CNC machining project? Contact our experts for a detailed quote and technical consultation.

Our Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

Response Time

Quote within 24 hours

Experience

15 years in precision CNC machining