- Home ›

- Mold Tooling ›

- Mold Tooling Manufacturing

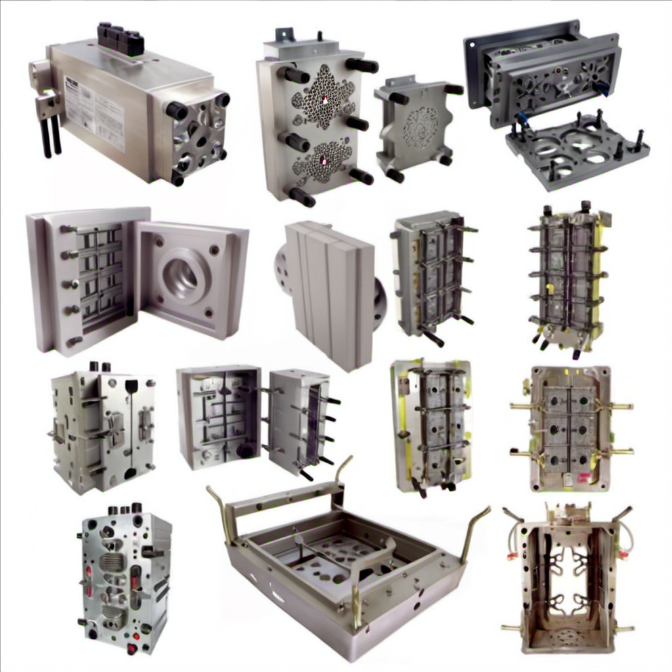

Expert Mold Tooling Manufacturing

Rapidaccu delivers comprehensive mold tooling solutions with 15 years of precision engineering experience, serving manufacturers worldwide from our advanced Shenzhen facility.

Our Mold Tooling Solutions

Specialized manufacturing capabilities across multiple mold types

Injection Mold

High-precision molds for thermoplastic production

Advanced injection molding solutions for complex plastic parts with tight tolerances and superior surface finish.

Stamping Die Tooling

Precision dies for metal forming operations

Progressive and transfer dies engineered for high-volume metal stamping with exceptional accuracy and durability.

Die Casting Mold

High-performance molds for metal casting

Robust die casting molds for aluminum, zinc, and magnesium alloys with optimized thermal management.

Comprehensive Mold Tooling Services

From concept to production, we deliver complete mold tooling solutions

Design Engineering

Mold Flow Analysis

CNC Machining

Heat Treatment

Quality Inspection

Mold Testing

Advanced Manufacturing Capabilities

Multi-Cavity Mold Technology

Our expertise in multi-cavity mold design maximizes production efficiency while maintaining precise cavity-to-cavity consistency. Advanced CAD/CAM systems ensure optimal gate placement, balanced runner systems, and uniform cooling channels for superior part quality.

Precision CNC Manufacturing

State-of-the-art 5-axis CNC machining centers and EDM equipment deliver exceptional accuracy for complex mold geometries. Our automated quality control systems verify dimensional integrity throughout the manufacturing process.

Material Science Expertise

Comprehensive understanding of tool steel properties enables optimal material selection for each application. We work with premium grades including P20, H13, S136, NAK80, and specialty alloys for demanding environments.

Technical Specifications

Quality Certifications

15 Years Excellence

Trusted by global manufacturers for consistent quality and reliable delivery

Mold Types We Manufacture

Injection Molds

Precision injection molds for thermoplastic and thermoset materials. From simple two-plate designs to complex multi-cavity hot runner systems, we deliver molds optimized for your production requirements.

- Standard and family molds

- Insert molding capabilities

- Overmolding solutions

Compression Molds

High-pressure compression molds for rubber, silicone, and composite materials. Engineered for optimal material flow, uniform pressure distribution, and consistent part quality.

- Rubber molding dies

- BMC/SMC composite molds

- Transfer molding tools

Blow Molds

Precision blow molds for hollow plastic products including containers, bottles, and complex shaped parts. Designed for excellent surface finish and dimensional stability.

- Extrusion blow molds

- Injection blow molds

- Stretch blow molds

Die Casting Molds

Robust die casting molds for aluminum, zinc, and magnesium alloys. Engineered to withstand high temperatures and pressures while maintaining precise dimensional control.

- Cold chamber dies

- Hot chamber dies

- Gravity casting molds

Serving Global Industries

Our mold tooling solutions support manufacturers across diverse sectors worldwide

Automotive

Interior components, exterior parts, lighting systems, and technical assemblies

Electronics

Precision housings, connectors, micro-components, and enclosures

Medical

Medical devices, diagnostic equipment, surgical instruments, and lab tools

Packaging

Containers, closures, caps, and specialized packaging solutions

Consumer Goods

Household products, toys, sporting goods, and retail items

Electrical

Switches, sockets, junction boxes, and electrical components

Agriculture

Irrigation components, machinery parts, and agricultural equipment

Construction

Fittings, fixtures, building materials, and architectural elements

From Design to Delivery

Project Consultation

Initial review of part requirements, material specifications, production volumes, and quality standards. Our engineering team provides technical recommendations and feasibility analysis.

Mold Design & Engineering

Comprehensive 3D modeling, mold flow simulation, cooling analysis, and detailed engineering drawings. DFM optimization ensures manufacturing efficiency and part quality.

Precision Manufacturing

Advanced CNC machining, EDM processing, surface finishing, and heat treatment. Continuous quality inspection throughout production ensures dimensional accuracy.

Testing & Validation

Comprehensive mold trials, dimensional verification, sample part inspection, and performance validation. Complete documentation package including CMM reports and first article inspection.

International Shipping

Secure packaging, export documentation, and global logistics coordination. Complete technical support and maintenance guidelines provided for long-term mold performance.

Common Questions About Mold Tooling

What factors affect mold tooling costs?

How long does mold manufacturing take?

Can you modify existing molds?

What quality documentation do you provide?

Do you offer mold warranty coverage?

Why choose Rapidaccu for mold tooling?

Partner With Rapidaccu

Experience the difference of working with a dedicated mold tooling manufacturer committed to your success

Contact Our Team

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Communication

info@rapidaccu.comManufacturing Experience

15 years of precision mold tooling excellence

What Sets Us Apart

Request Your Quotation

Share your project details and receive a comprehensive proposal from our engineering team