- Home ›

- Mold Tooling ›

- Injection Mold

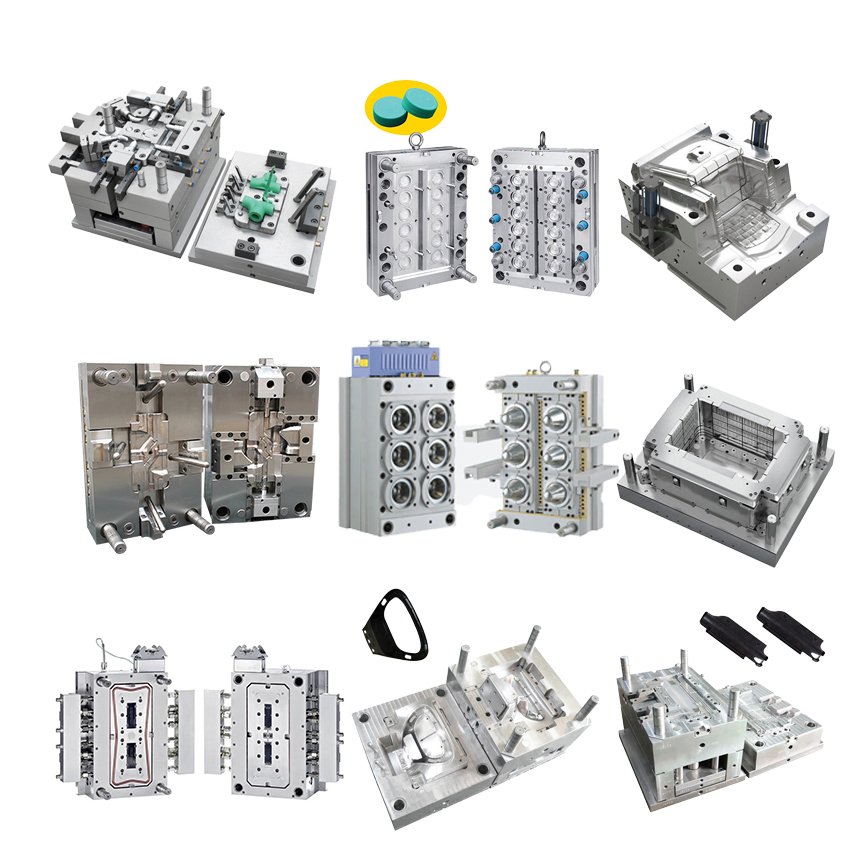

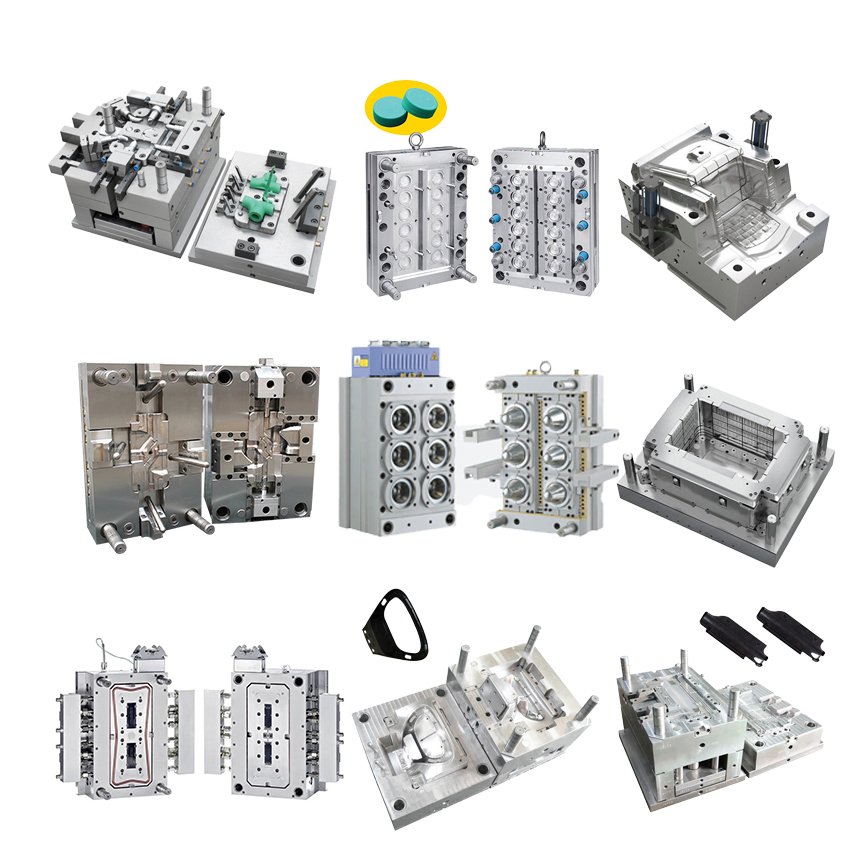

Precision Injection Mold Manufacturing

With 15 years of expertise, Rapidaccu delivers high-precision injection molds engineered for reliability, durability, and optimal performance in mass production environments.

Request a Quote

Why Choose Rapidaccu for Injection Molds

Combining advanced CNC technology with 15 years of manufacturing excellence

Advanced CNC Precision

State-of-the-art CNC machining ensures tight tolerances and consistent quality across all injection mold components.

Superior Durability

Premium materials and expert craftsmanship deliver injection molds built to withstand millions of production cycles.

15 Years Expertise

Extensive experience in complex injection mold design and manufacturing across diverse industries and applications.

Comprehensive Injection Mold Solutions

At Rapidaccu, we specialize in full-service injection mold manufacturing from initial design consultation through final production validation. Our facility in Shenzhen combines cutting-edge technology with skilled craftsmanship.

- Custom mold design and engineering support

- Multi-cavity and complex geometry capabilities

- Precision mold testing and validation

- Complete quality assurance documentation

Our Mold Specifications

Our Injection Mold Manufacturing Process

Design Analysis

Comprehensive review of part design and mold flow analysis to optimize manufacturability

Mold Engineering

Detailed mold design with CAD/CAM technology ensuring optimal cooling and ejection systems

CNC Machining

Precision CNC manufacturing of all mold components to exact specifications

Testing & Delivery

Rigorous mold trials and quality verification before international shipment

Quality Assurance Standards

Material Inspection

Verified steel grades and material certifications for every mold

Dimensional Verification

CMM inspection ensures all critical dimensions meet specifications

Performance Testing

Multiple trial runs validate part quality and cycle consistency

Uncompromising Quality Control

Every injection mold manufactured at Rapidaccu undergoes stringent quality control protocols. Our commitment to excellence ensures your molds deliver consistent performance throughout their operational life.

From material selection to final inspection, we maintain comprehensive quality documentation and traceability for complete peace of mind.

Discuss Your ProjectIndustries We Serve

Delivering specialized injection mold solutions across multiple sectors

Automotive Components

High-volume molds for interior, exterior, and under-hood applications

Consumer Electronics

Precision molds for housings, enclosures, and technical components

Medical Devices

Clean-room compatible molds for medical and laboratory equipment

Home Appliances

Durable molds for household products and consumer goods

Packaging Solutions

Multi-cavity molds for high-speed packaging production

Industrial Equipment

Heavy-duty molds for machinery parts and industrial applications

Frequently Asked Questions

What materials can be used for injection molds?

What is the typical lifespan of an injection mold?

Can you design molds for complex geometries?

Do you provide mold testing before shipment?

What information do you need to quote an injection mold?

What makes Rapidaccu different from other mold manufacturers?

Get Your Injection Mold Quote Today

Contact Rapidaccu for expert consultation and competitive pricing

Contact Information

Factory Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comExperience

15 years of professional mold manufacturing expertise

Why Choose Us

- ISO-certified manufacturing facility

- Comprehensive quality documentation

- Global shipping capabilities

- Dedicated customer support team