- Home ›

- Mold Tooling ›

- Stamping Die Tooling

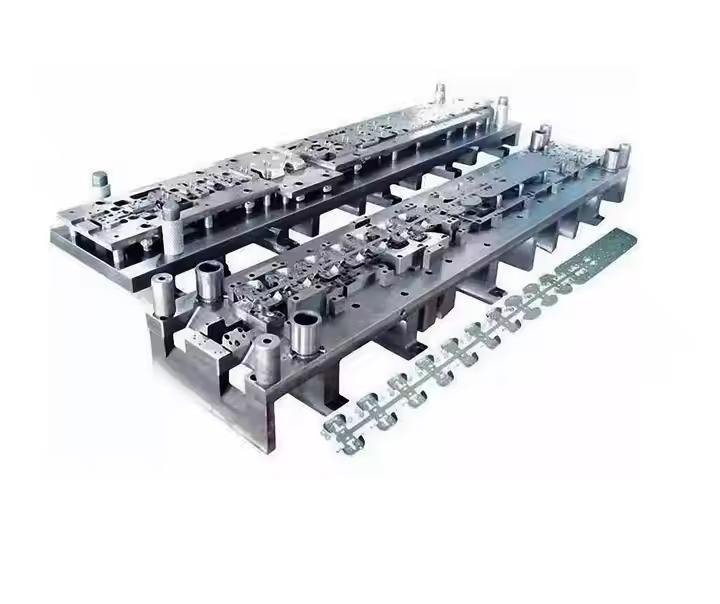

Professional Stamping Die Tooling

Rapidaccu specializes in high-precision stamping die tooling, combining 15 years of expertise with advanced CNC technology to deliver superior metal forming solutions for global manufacturers.

Progressive Dies

Multi-station dies for high-volume production efficiency

Transfer Dies

Precise part transfer for complex forming operations

Compound Dies

Combined operations in single press stroke

Line Dies

Sequential tooling for automated production lines

Advanced Stamping Die Capabilities

Precision Engineering & Design

Our engineering team utilizes cutting-edge CAD/CAM software for die design optimization. We conduct comprehensive material flow analysis, stress simulation, and spring-back calculations to ensure first-time-right production.

- 3D simulation and virtual tryout

- DFM analysis and optimization suggestions

CNC Manufacturing Excellence

State-of-the-art CNC machining centers deliver exceptional accuracy for all die components. Our 5-axis capabilities handle complex geometries, while EDM processes ensure perfect cavity details and surface finishes.

- Multi-axis CNC machining centers

- Wire EDM and sinker EDM capabilities

Quality Verification Process

Every stamping die undergoes rigorous testing and inspection protocols. CMM verification, hardness testing, and production trials validate performance before shipment, ensuring your tooling meets exact specifications.

- Complete dimensional inspection reports

- Sample parts and tryout documentation

Material Expertise

Comprehensive knowledge across all stamping die materials

Tool Steel Selection

Heat Treatment

Precision heat treatment processes optimize die performance and longevity:

- Vacuum hardening for minimal distortion

- Controlled tempering for optimal toughness

- Surface hardening treatments available

Surface Coating

Advanced coatings extend die life and improve performance:

- TiN/TiCN coating for wear resistance

- Chrome plating for corrosion protection

- Nitriding for surface hardness

Application Industries

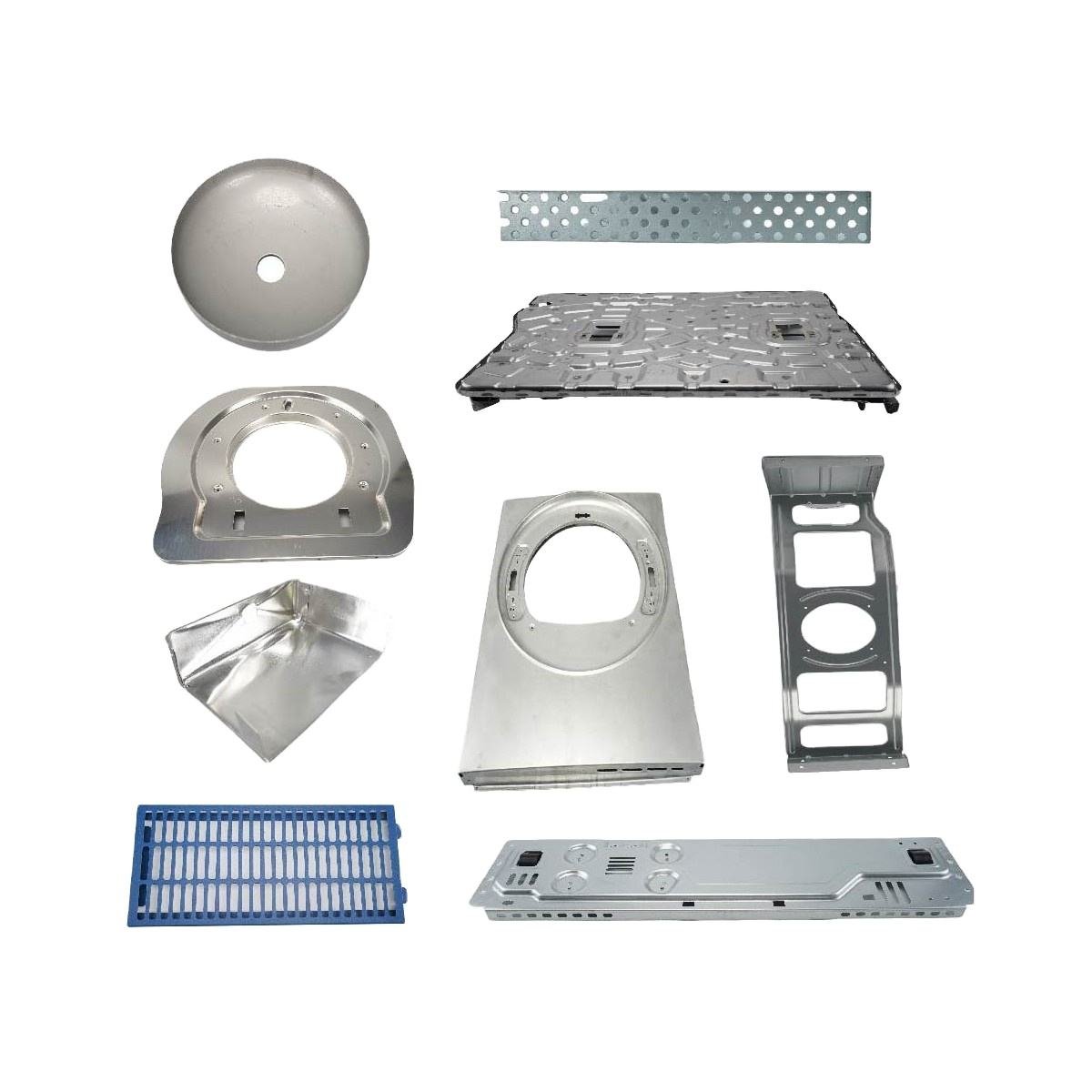

Our stamping die tooling serves manufacturers across diverse industrial sectors worldwide

Automotive

Body panels, brackets, structural components, and precision automotive parts requiring tight tolerances and high production volumes.

- Chassis components

- Interior hardware

- Fastening systems

Electronics

Precision enclosures, EMI shields, connectors, and intricate electronic component housings with micro-tolerance requirements.

- Device housings

- Heat sinks

- Contact terminals

Appliances

Durable components for home and commercial appliances including metal casings, functional parts, and aesthetic trim pieces.

- Control panels

- Mounting brackets

- Door assemblies

Our Development Process

Initial Consultation

Review part specifications, production requirements, and technical feasibility assessment

Die Design

Complete CAD modeling, simulation analysis, and design optimization for manufacturability

Precision Machining

CNC manufacturing of die components with strict quality control and dimensional verification

Assembly & Testing

Professional die assembly, alignment verification, and comprehensive tryout validation

Delivery & Support

Secure international shipping with complete documentation and ongoing technical support

Frequently Asked Questions

What types of stamping dies do you manufacture?

What is the typical die life expectancy?

Can you handle tight tolerance requirements?

Do you provide die maintenance services?

What information is needed for a quote?

Why choose Rapidaccu for stamping die tooling?

Start Your Stamping Die Project

Partner with Rapidaccu for precision tooling solutions backed by 15 years of manufacturing excellence

Contact Rapidaccu

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comIndustry Experience

15 years of precision die manufacturing expertise