- Home ›

- Plastic Machining ›

- Acetal Delrin POM Machining

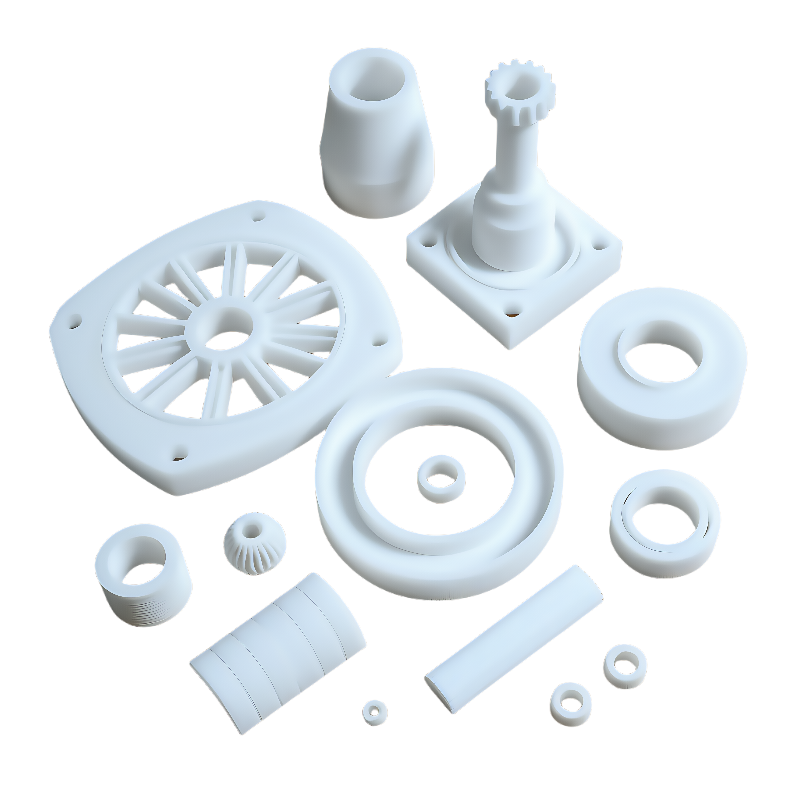

Acetal/Delrin/POM Machining

Precision engineered POM parts from China’s leading manufacturer

- 15 Years Specializing in POM Component Manufacturing

- Advanced CNC & 3D Printing Technologies

- Superior Quality Control & ISO Certification

- Reliable Global Export Partner

Understanding Acetal/Delrin/POM Material

Acetal, also known as POM (Polyoxymethylene) or by the trade name Delrin, is a high-performance engineering thermoplastic renowned for its excellent mechanical properties, dimensional stability, and low friction characteristics. This crystalline polymer exhibits outstanding strength, stiffness, and wear resistance, making it a preferred choice for precision mechanical components.

POM material combines the best attributes of metals and plastics – it offers high tensile strength and rigidity comparable to metals while maintaining the lightweight and corrosion-resistant benefits of plastics. Its natural lubricity and low moisture absorption make it ideal for moving parts and precision mechanisms.

At Rapidaccu, we leverage our 15 years of expertise to manufacture precision POM components using state-of-the-art CNC machining and 3D printing technologies. Our manufacturing capabilities ensure tight tolerances, excellent surface finishes, and consistent quality for demanding applications across multiple industries.

POM Manufacturing Technologies

CNC Machining Acetal/Delrin/POM

High-precision CNC milling and turning for complex POM parts with exceptional accuracy and superior surface quality.

Explore Service

POM 3D Printing

Cutting-edge additive manufacturing for rapid prototyping and complex POM geometries with design freedom.

Explore Service

POM Injection Molding

High-volume injection molding for mass production of POM parts with consistent quality.

Explore ServiceOutstanding POM Material Properties

High Mechanical Strength

Exceptional tensile strength and rigidity for structural applications.

Dimensional Stability

Maintains precise dimensions under varying conditions.

Low Friction Coefficient

Natural lubricity ideal for moving parts and bearings.

Low Moisture Absorption

Resists moisture for consistent performance.

Excellent Wear Resistance

Long-lasting performance in high-wear applications.

Chemical Resistance

Withstands exposure to solvents and chemicals.

Easy Machinability

Excellent machining properties for precision parts.

Wide Temperature Range

Performs reliably from -40°C to 100°C.

Manufacturing Excellence

ISO Certified Quality

Rigorous quality management systems ensuring consistent excellence.

Advanced Inspection

State-of-the-art measurement equipment for precision verification.

Expert Engineering Team

Experienced professionals dedicated to your project success.

Why Choose Rapidaccu for POM Machining?

15 Years Industry Experience

Proven track record in precision POM parts manufacturing

Cutting-Edge Technology

Latest CNC machines and 3D printing equipment

Competitive Pricing

Cost-effective solutions for international markets

Global Shipping Expertise

Reliable delivery to customers worldwide

POM Machining Capabilities

Precision CNC Milling

Multi-axis CNC milling with tolerances down to ±0.025mm for complex POM components.

CNC Turning Operations

High-precision turning for cylindrical POM parts including bushings, shafts, and rollers.

Additive Manufacturing

Advanced 3D printing for rapid prototyping and complex geometries impossible with traditional methods.

Tight Tolerance Control

Achieving and maintaining precise dimensional accuracy for critical applications.

Surface Finishing

Multiple finishing options including polishing, grinding, and coating for optimal performance.

Quality Assurance

Comprehensive inspection and testing to ensure parts meet or exceed specifications.

Injection Molding

High-volume injection molding for mass production of POM parts with consistent quality.

Common POM Applications

Gears & Bearings

Precision gears, bushings, bearings, and sliding components for mechanical systems.

Automotive Parts

Fuel system components, window mechanisms, door lock parts, and interior components.

Electrical Insulators

Insulating components, switch housings, and electrical connector parts.

Medical Devices

Surgical instrument parts, metering devices, and medical equipment components.

Consumer Products

Zippers, fasteners, plumbing fittings, and precision household components.

Industrial Equipment

Conveyor components, valve parts, pump elements, and machinery components.

Frequently Asked Questions

What is the difference between Acetal, Delrin, and POM?

What tolerances can be achieved with POM machining?

Is POM suitable for food contact applications?

Can POM parts be used in high-wear applications?

What surface finishes are available for POM parts?

Do you provide material certificates for POM parts?

Request Your POM Machining Quote

Partner with China’s trusted POM parts manufacturer

Rapidaccu Manufacturing

Our Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Us

info@rapidaccu.comExperience

15 Years in Precision POM Manufacturing

Our Commitment

- ISO Quality Management

- Worldwide Shipping

- Technical Support

- Competitive Export Pricing