- Home ›

- Sheet Metal Fabrication

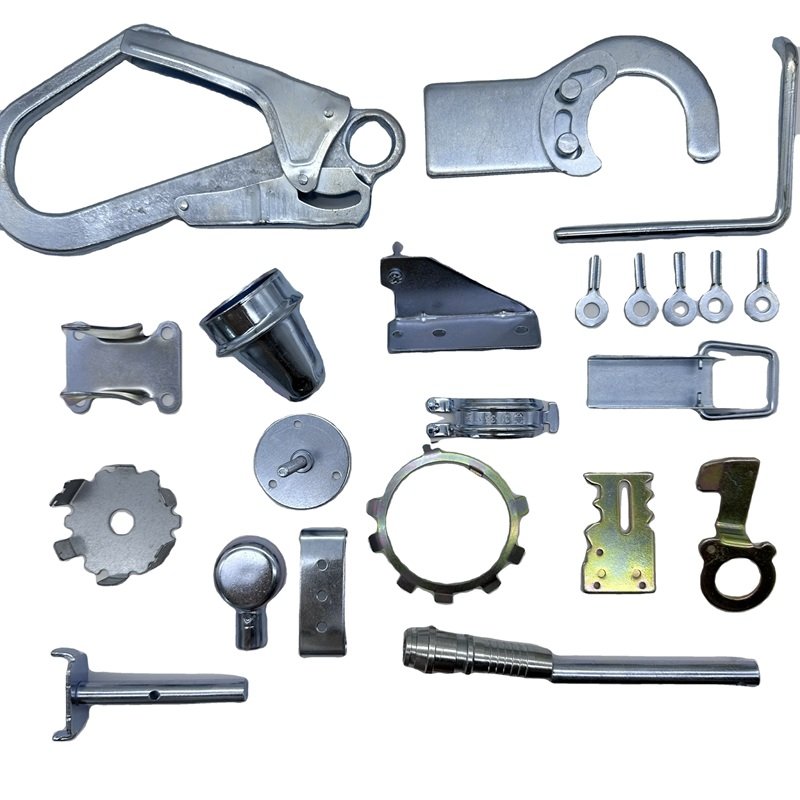

Custom Sheet Metal Fabrication Services

Professional sheet metal components and assemblies from China. Rapidaccu delivers precision-fabricated metal parts with comprehensive capabilities from laser cutting to finishing. Trusted by manufacturers worldwide for 15 years.

Sheet Metal Fabrication Capabilities

Our comprehensive sheet metal fabrication service combines advanced equipment with skilled craftsmanship. We offer end-to-end solutions from design support to final finishing, ensuring precision quality parts for your prototyping and production needs.

Laser Cutting

Advanced fiber laser cutting technology for precise cuts in sheet metal materials. Create complex patterns, intricate geometries, and tight tolerances with clean edges and minimal heat-affected zones.

- Precision cutting to ±0.1mm tolerance

- Complex geometries and patterns

- Clean edges, minimal burring

Bending & Forming

CNC press brake forming uses precision punch and die sets to create accurate bends along straight axes. Achieve repeatable accuracy for complex part geometries with multiple bends and angles.

- CNC-controlled precision bending

- Complex multi-bend geometries

- Repeatable accuracy across batches

Punching & Stamping

High-precision CNC turret punching combines punch tools with bottom dies to cut profiles and form specific patterns. Progressive die stamping enables high-volume production with consistent quality.

- Holes, slots, and cutouts

- Progressive die stamping

- High-volume production capability

Welding & Assembly

Professional TIG and MIG welding services for sheet metal assemblies. Join multiple components through welding, riveting, or hardware insertion to create complete fabricated products.

- TIG and MIG welding

- Hardware insertion and riveting

- Complete assembly services

How Sheet Metal Fabrication Works

Our Manufacturing Process

Laser Cutting

Thin sheet metal stock is placed on a flat bed where our fiber laser cutter draws programmed part patterns with exceptional precision and clean edges.

Punching Features

Depending on part geometry, our CNC punch press forms additional features like holes, countersinks, and specialized patterns using precision tooling.

Press Brake Forming

Once deburred, parts move to our CNC press brakes where they are bent and formed into final three-dimensional geometries with precise angles.

Finishing & Assembly

Final operations include welding, hardware insertion, surface treatments, and quality inspection to ensure parts meet specifications.

Advantages of Sheet Metal Fabrication

-

Low Material WasteEfficient nesting and cutting minimize scrap material

-

Scalable ProductionCost-effectively scale from prototypes to production volumes

-

Multiple Finishing OptionsPowder coating, anodizing, plating, and more

-

Strong and DurableExcellent structural integrity for functional parts

-

Wide Material SelectionAluminum, stainless steel, copper, brass, and more

Sheet Metal Materials We Work With

Choose from our extensive selection of sheet metal materials. Each material offers unique properties for different applications, from lightweight aluminum to corrosion-resistant stainless steel.

Aluminum

Lightweight, corrosion-resistant, excellent for aerospace and electronics.

Learn More

Stainless Steel

Superior corrosion resistance, ideal for food processing and medical equipment.

Learn More

Steel

High strength and durability, cost-effective for structural applications.

Learn More

Copper

Excellent electrical conductivity, superior thermal properties for electronics.

Learn More

Bronze

Excellent wear resistance, ideal for bearings and marine applications.

Learn More

Titanium

High strength-to-weight ratio, perfect for aerospace and medical devices.

Learn More

Tool Steel

Extreme hardness and wear resistance for demanding tooling applications.

Learn More

Inconel

High-temperature strength, oxidation resistance for extreme environments.

Learn More

Brass

Attractive appearance, excellent machinability, ideal for decorative applications.

Learn MoreAdditional materials available:

Common Sheet Metal Applications

Electronics Enclosures

Protective housings for computers, servers, and electronic equipment

Chassis & Cabinets

Structural frames, equipment racks, and control cabinets

Brackets & Mounts

Support brackets, mounting plates, and positioning hardware

Covers & Panels

Access panels, protective covers, and decorative trim

Automotive Parts

Body panels, brackets, heat shields, and structural components

Medical Equipment

Instrument housings, carts, and medical device components

Industrial Machinery

Machine guards, housings, and functional components

Appliances

Housings, doors, and functional parts for home appliances

Why Choose Rapidaccu for Sheet Metal?

We combine advanced manufacturing technology with 15 years of expertise to deliver high-quality sheet metal components for clients worldwide.

Advanced Equipment

State-of-the-art fiber laser cutters, CNC press brakes, and turret punch presses ensure precision and repeatability.

Experienced Team

Our skilled engineers and technicians have 15 years of experience in sheet metal fabrication and manufacturing.

ISO Certified

ISO 9001:2015 certified facility with documented quality management systems and rigorous inspection procedures.

Scalable Production

From single prototypes to production runs of thousands of parts, we scale efficiently to meet your volume needs.

Complete Finishing

In-house powder coating, plating, anodizing, and other finishing services provide complete turnkey solutions.

Global Shipping

We ship worldwide with reliable logistics partners, serving customers in over 50 countries across all continents.

Frequently Asked Questions

What sheet metal thicknesses can you fabricate?

What is your typical lead time for sheet metal parts?

What are your minimum order quantities?

Do you provide design support for sheet metal parts?

What finishing options are available?

Can you provide material certifications?

Start Your Sheet Metal Project

Partner with Rapidaccu for professional sheet metal fabrication services. Our comprehensive capabilities and experienced team ensure your components meet specifications for quality, precision, and performance.

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comManufacturing Experience

15 Years of Precision Sheet Metal Fabrication Excellence

Request a Quote

Our team typically responds within 24 hours with a detailed quote including lead time and shipping options.