- Home ›

- Sheet Metal Fabrication ›

- Brass Sheet Metal Fabrication

Brass Sheet Metal Fabrication

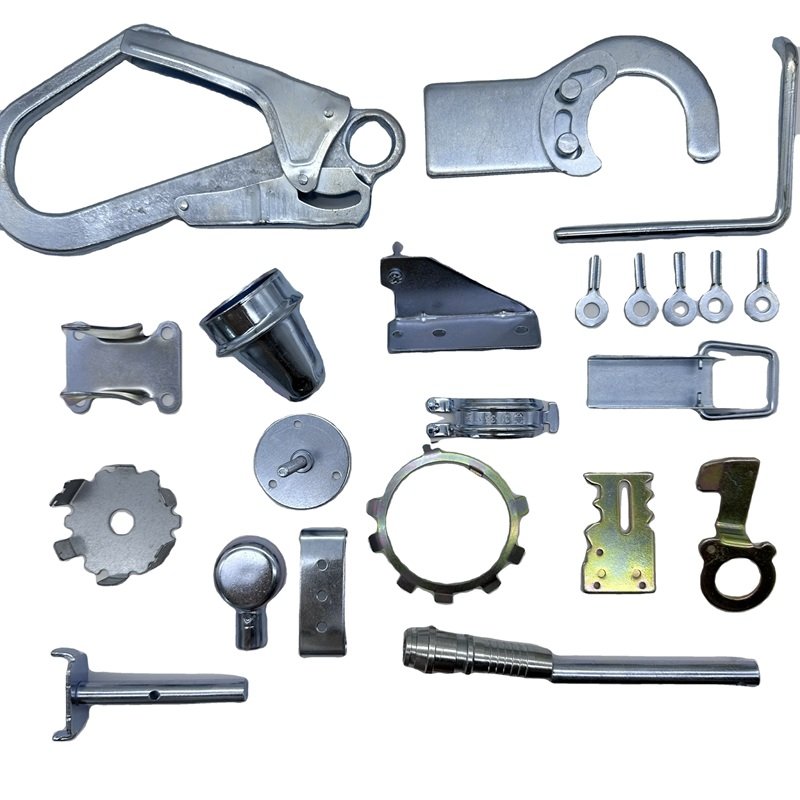

Rapidaccu specializes in precision brass sheet metal fabrication with 15 years of advanced manufacturing experience. We deliver high-quality brass components featuring excellent corrosion resistance, superior machinability, and attractive golden appearance for decorative and functional applications.

Why Choose Brass for Sheet Metal Fabrication?

Brass offers a unique combination of properties that make it ideal for both functional and decorative applications

Aesthetic Appeal

Beautiful golden appearance that develops an attractive patina over time. Ideal for decorative applications, architectural elements, and consumer products requiring visual appeal.

Corrosion Resistance

Excellent resistance to corrosion and tarnishing in various environments. Superior performance in marine applications, plumbing systems, and outdoor installations exposed to moisture.

Excellent Machinability

Superior machinability allows for intricate designs and tight tolerances. Easy to cut, form, and finish, resulting in faster production times and reduced manufacturing costs.

Good Conductivity

Excellent electrical and thermal conductivity makes brass suitable for electrical components, connectors, terminals, and heat exchange applications requiring efficient energy transfer.

Non-Magnetic

Non-ferromagnetic properties make brass ideal for applications requiring non-magnetic materials, such as electronic enclosures, navigational equipment, and precision instruments.

Low Friction

Low friction coefficient reduces wear in moving parts. Perfect for bearings, bushings, gears, and valve components requiring smooth operation and extended service life.

Brass Alloys & Grades We Fabricate

We work with a comprehensive range of brass alloys optimized for specific performance requirements

C26000 (Cartridge Brass)

70% Cu / 30% ZnProperties: Excellent cold working, deep drawing capability

Characteristics: Good corrosion resistance, moderate strength

Most common brass alloy offering excellent formability and moderate strength. Superior cold working properties make it ideal for deep drawn components and complex geometries.

Typical Applications:

- Ammunition casings and shells

- Automotive radiator cores

- Plumbing fixtures and fittings

- Lamp fixtures and lighting components

C27000 (Yellow Brass)

65% Cu / 35% ZnProperties: Good strength, excellent formability

Characteristics: Superior machinability, attractive finish

General-purpose brass with good balance of strength and ductility. Excellent for spinning, bending, and forming operations with superior surface finish quality.

Typical Applications:

- Architectural trim and hardware

- Musical instrument parts

- Decorative panels and nameplates

- Clock and watch components

C28000 (Muntz Metal)

60% Cu / 40% ZnProperties: High strength, economical

Characteristics: Good corrosion resistance, hot workable

High-zinc brass offering excellent strength and corrosion resistance at economical cost. Best suited for hot working operations and applications requiring higher strength.

Typical Applications:

- Marine hardware and fittings

- Condenser tubes and plates

- Architectural panels

- Brazing rods and wire

C23000 (Red Brass)

85% Cu / 15% ZnProperties: Excellent corrosion resistance

Characteristics: Good formability, attractive red color

High-copper brass with superior corrosion resistance and excellent formability. Distinctive reddish color makes it popular for decorative and architectural applications.

Typical Applications:

- Weatherstripping and gaskets

- Decorative architectural elements

- Plumbing and HVAC components

- Electrical connectors and terminals

Brass Sheet Metal Fabrication Services

Precision Laser Cutting

Advanced fiber laser cutting technology for brass sheets. Achieve intricate patterns, complex geometries, and tight tolerances with clean edges and minimal heat-affected zones for superior part quality.

CNC Press Brake Forming

Precision CNC press brake bending of brass sheets. Create accurate bends, folds, and complex geometries with repeatable precision. Computer-controlled forming ensures consistent quality across production runs.

Punching & Stamping

High-precision CNC turret punching for holes, slots, and cutouts. Progressive die stamping enables high-volume production with consistent quality and minimal material waste for cost-effective manufacturing.

Welding & Brazing

Specialized TIG welding and brazing for brass assemblies. Join multiple brass components or combine brass with other metals. Creates strong, leak-proof joints while maintaining material integrity and appearance.

Surface Finishing

Comprehensive finishing services including polishing, brushing, lacquering, and patina application. Enhance appearance, prevent tarnishing, and protect brass components for long-lasting beauty and performance.

Industries & Applications

Musical Instruments

Brass components for trumpets, saxophones, trombones, and other wind instruments requiring superior acoustic properties and corrosion resistance.

Architectural Hardware

Door handles, hinges, railings, decorative panels, and trim elements where aesthetic appeal and durability are essential requirements.

Electrical Components

Connectors, terminals, switch contacts, and grounding components utilizing brass’s excellent electrical conductivity and corrosion resistance.

Plumbing & HVAC

Valves, fittings, manifolds, and heat exchangers benefiting from brass’s corrosion resistance and antimicrobial properties in water systems.

Marine Applications

Marine hardware, propellers, portholes, and navigation equipment requiring excellent corrosion resistance in saltwater environments.

Decorative Products

Nameplates, plaques, trophies, and ornamental items where brass’s attractive appearance and patina development enhance visual appeal.

Quality Assurance & Inspection

Material Verification

Spectroscopic analysis confirms brass composition and alloy grade. Mill certificates provided for complete material traceability and compliance documentation.

Dimensional Inspection

CMM and precision measuring equipment ensure all dimensions meet drawing specifications. First article inspection and in-process verification guarantee consistency.

Visual Inspection

Thorough examination for surface defects, burrs, scratches, and finish quality. Ensures parts meet aesthetic requirements for decorative applications.

ISO Certification

ISO 9001:2015 certified facility with documented quality management systems. Rigorous procedures ensure consistent quality and continuous improvement.

Frequently Asked Questions

What brass alloys are best for sheet metal fabrication?

Does brass tarnish and how can it be prevented?

What thicknesses of brass sheet can you fabricate?

Can brass be welded or joined to other metals?

What finishing options are available for brass parts?

Is brass suitable for outdoor applications?

More Materials for Your Projects

Browse our full selection of precision fabricated materials

Start Your Brass Sheet Metal Project

Partner with Rapidaccu for precision brass sheet metal fabrication. Our specialized expertise in brass alloys and comprehensive finishing capabilities ensure your components meet the highest standards for quality, appearance, and performance.

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comManufacturing Experience

15 Years of Precision Brass Fabrication Excellence

Request a Quote

Our team typically responds within 24 hours with detailed quotes for brass sheet metal fabrication projects.