- Home ›

- Sheet Metal Fabrication ›

- Cast Iron Sheet Metal Fabrication

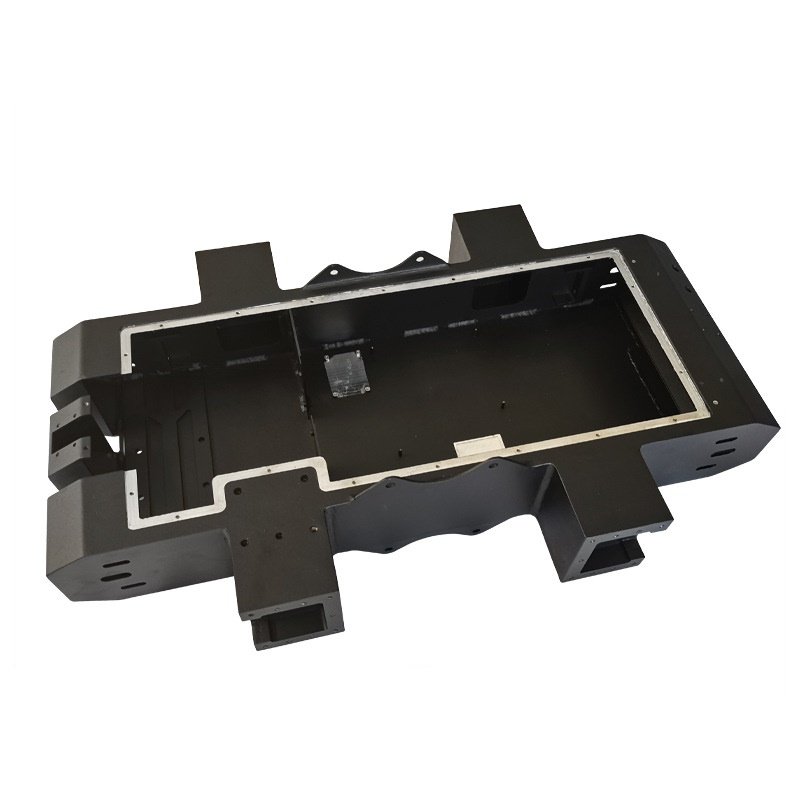

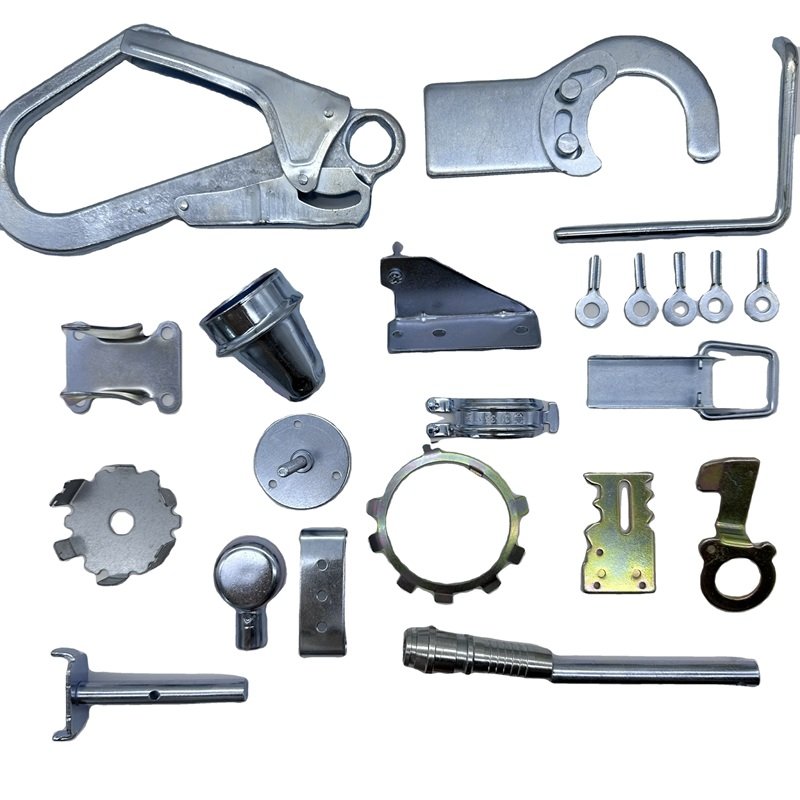

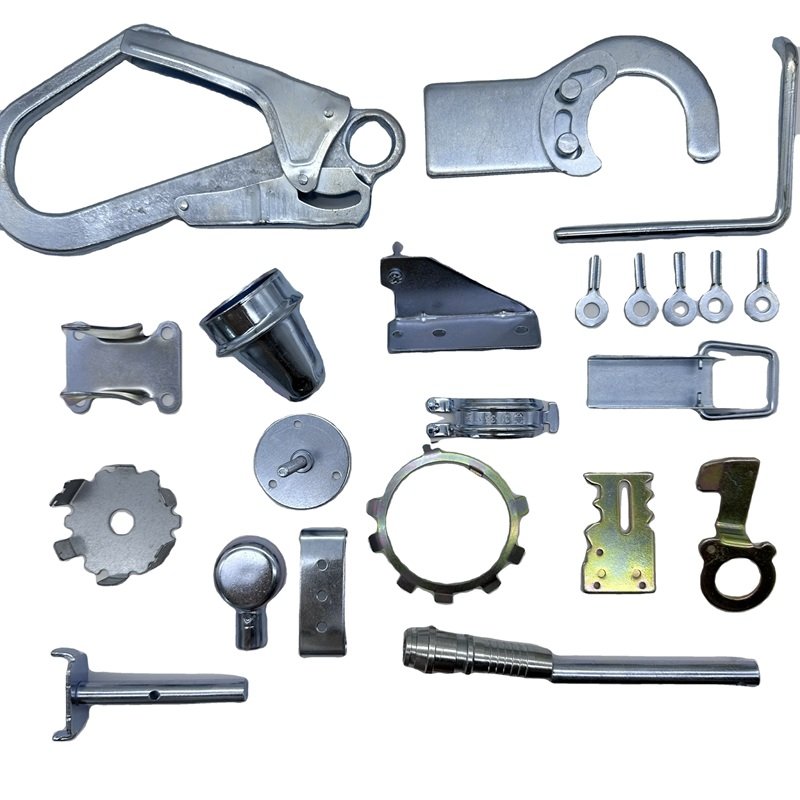

Cast Iron Sheet Metal Fabrication

Rapidaccu delivers specialized cast iron sheet metal fabrication with 15 years of manufacturing expertise. We produce durable, wear-resistant cast iron components for automotive, machinery, and heavy industrial applications requiring exceptional damping properties and thermal stability.

Cast Iron Performance Advantages

Unique properties make cast iron ideal for demanding industrial applications

Exceptional Wear Resistance

Graphite flakes provide self-lubricating properties reducing friction and wear. Superior abrasion resistance extends component life in harsh environments.

Vibration Damping

Outstanding damping capacity absorbs vibrations and reduces noise. Ideal for machine bases, engine blocks, and precision equipment foundations.

Thermal Stability

Excellent thermal conductivity and low thermal expansion. Maintains dimensional stability across temperature fluctuations and thermal cycling.

High Compressive Strength

Superior compressive strength compared to tensile strength. Excellent for applications involving heavy loads and bearing pressures.

Cost-Effective

Lower material costs than steel alloys with excellent castability. Complex shapes can be produced economically through casting processes.

Excellent Machinability

Gray cast iron machines easily producing good surface finishes. Graphite flakes act as chip breakers reducing tool wear during machining.

Cast Iron Types & Specifications

Different cast iron grades optimized for specific performance requirements

Gray Cast Iron

Carbon Content: 2.5-4.0%

Microstructure: Graphite flakes in ferrite/pearlite matrix

Most widely used cast iron with excellent machinability, wear resistance, and vibration damping. Graphite flakes provide lubricity and chip breaking during machining.

Typical Applications:

- Engine blocks and cylinder heads

- Machine tool bases and frames

- Brake rotors and drums

- Pump housings and manifolds

Ductile Iron

Carbon Content: 3.0-4.0%

Microstructure: Spheroidal graphite nodules

Also known as nodular iron, offers higher strength, toughness, and ductility than gray iron. Spheroidal graphite provides improved mechanical properties while maintaining castability.

Typical Applications:

- Crankshafts and gears

- Suspension components

- Heavy-duty valve bodies

- Wind turbine components

White Cast Iron

Carbon Content: 2.5-3.5%

Microstructure: Carbide structure, no graphite

Extremely hard and wear-resistant but brittle. Carbon exists as iron carbide rather than graphite. Excellent for applications requiring maximum abrasion resistance.

Typical Applications:

- Crushing equipment liners

- Grinding mill components

- Wear plates and surfaces

- Mining equipment parts

Malleable Iron

Process: Heat-treated white iron

Microstructure: Temper carbon nodules

White cast iron heat-treated to convert carbides into graphite nodules. Offers good ductility and impact resistance with moderate strength and excellent machinability.

Typical Applications:

- Pipe fittings and flanges

- Agricultural equipment

- Hand tools and wrenches

- Railroad equipment

Fabrication & Machining Services

CNC Machining

Precision milling, turning, and drilling operations. Specialized tooling and cutting parameters optimized for cast iron’s unique characteristics.

Surface Grinding

Precision surface finishing for flatness and parallelism requirements. Achieves tight tolerances and smooth finishes on critical mating surfaces.

Boring & Honing

Internal cylinder boring and honing for precise diameters. Critical for engine blocks, hydraulic cylinders, and bearing housings.

Tapping & Threading

Thread cutting and tapping operations for fastener holes. Proper thread engagement ensures secure assembly in cast iron components.

Surface Treatment

Painting, powder coating, and rust prevention treatments. Protective coatings extend service life in corrosive environments.

Quality Inspection

Dimensional verification, hardness testing, and non-destructive testing. CMM inspection ensures all specifications are met.

Industrial Applications

Automotive

Engine blocks, brake components, transmission housings

Heavy Machinery

Machine bases, frames, gearbox housings

Pumps & Valves

Pump housings, valve bodies, impellers

Construction

Counterweights, wear plates, ground supports

Railroad

Brake shoes, couplings, bearing caps

Agriculture

Tractor parts, implement components

Material Handling

Conveyor components, crane parts

Machine Tools

Lathe beds, milling tables, fixtures

Rapidaccu Cast Iron Expertise

Decades of experience in cast iron fabrication and machining

Specialized Tooling

Carbide and ceramic tooling optimized for cast iron’s abrasive nature and graphite content.

Skilled Machinists

Experienced operators understand cast iron’s unique machining requirements and best practices.

Quality Systems

ISO 9001:2015 certified processes ensure consistent quality and traceability throughout fabrication.

15 Years Experience

Proven track record delivering precision cast iron components for diverse industrial applications.

Frequently Asked Questions

What is the difference between gray and ductile iron?

Can cast iron be welded?

Why is cast iron preferred for machine bases?

What machining tolerances can you achieve?

Do you provide cast iron material or only machining?

How do you prevent rust on cast iron parts?

More Sheet Metal Materials

Explore our full range of precision fabrication capabilities

Aluminum

Lightweight & corrosion-resistant

Brass

Antimicrobial & decorative excellence

Bronze

Wear-resistant & marine-grade

Copper

Superior electrical conductivity

Stainless Steel

Hygienic & corrosion-proof

Steel

Strong & cost-effective

Titanium

Aerospace-grade strength

Tool Steel

Exceptional hardness & wear resistance

Inconel

High-temperature superalloy

More Sheet Metal Materials

Explore our full spectrum of precision fabrication capabilities

Aluminum

Lightweight champion for aerospace

Stainless Steel

Corrosion-resistant excellence for demanding environments

Bronze

Classic alloy for bearings and marine

Steel

Reliable strength for structural applications

Copper

Superior conductivity for electrical systems

Titanium

Aerospace-grade strength-to-weight ratio

Tool Steel

Hardened precision for tooling and dies

Inconel

Extreme temperature superalloy performance

Brass

Decorative and antimicrobial properties

Request Cast Iron Fabrication Quote

Partner with Rapidaccu for expert cast iron sheet metal fabrication and machining. Our 15 years of experience ensures your components meet the highest standards for wear resistance, damping, and dimensional accuracy in industrial applications.

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comManufacturing Experience

15 Years in Cast Iron Fabrication Excellence