- Home ›

- Sheet Metal Fabrication ›

- Steel Sheet Metal Fabrication

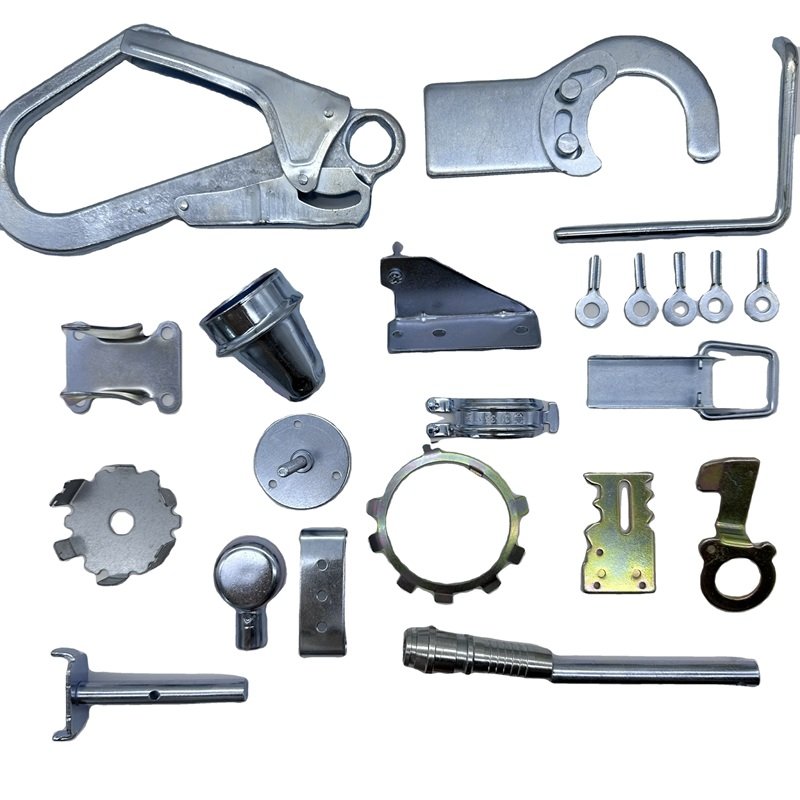

Steel Sheet Metal Fabrication

Rapidaccu specializes in high-quality steel sheet metal fabrication with 15 years of manufacturing expertise. We deliver robust, cost-effective steel components for industrial applications with precision and reliability.

Why Steel Sheet Metal?

Steel offers unmatched strength, versatility, and cost-effectiveness for demanding applications

Exceptional Strength

Steel provides superior tensile strength and structural integrity for heavy-duty applications requiring maximum load-bearing capacity.

Cost-Effective

Affordable material costs combined with excellent durability make steel ideal for budget-conscious projects without compromising quality.

Versatile Formability

Excellent formability allows for complex bends, shapes, and designs while maintaining structural properties and dimensional accuracy.

Magnetic Properties

Ferromagnetic characteristics make steel suitable for electromagnetic applications, shielding, and magnetic mounting solutions.

Weldable

Excellent weldability enables strong joints and complex assemblies using various welding techniques for secure construction.

Recyclable

Fully recyclable material supports sustainable manufacturing practices and environmental responsibility throughout its lifecycle.

Steel Types & Specifications

Cold Rolled Steel

Processed below recrystallization temperature for superior surface finish and tighter tolerances. Smooth, scale-free surface with improved mechanical properties.

Hot Rolled Steel

Processed at high temperatures above recrystallization point. Cost-effective for large-scale projects with less critical tolerance requirements and surface finish needs.

Galvanized Steel

Coated with protective zinc layer for enhanced corrosion resistance. Ideal for outdoor applications, HVAC systems, and environments with moisture exposure.

Standard Cold Rolled Steel

General-purpose cold rolled steel with excellent deep drawing capabilities. Perfect for precision parts, automotive components, and consumer products.

Steel Sheet Metal Fabrication Services

Laser & Plasma Cutting

Advanced laser and plasma cutting for complex patterns on steel sheets with exceptional accuracy and clean edges.

Press Brake Bending

Precision press brake forming for complex bends and shapes in steel sheet metal with tight tolerance capabilities.

MIG/TIG Welding

Expert MIG, TIG, and spot welding for steel sheet metal assemblies ensuring strong joints and structural integrity.

Stamping & Punching

Progressive die stamping and high-speed punching for volume production of steel sheet metal components.

Surface Finishing

Powder coating, painting, galvanizing, and plating services for corrosion protection and aesthetic enhancement.

Assembly Services

Complete assembly including hardware installation and component integration for turnkey steel sheet metal solutions.

Applications & Industries

Manufacturing

Equipment enclosures, machinery frames

Automotive

Body panels, chassis components

Construction

Structural supports, brackets

Electronics

Enclosures, racks, cabinets

HVAC

Ductwork, vents, air handlers

Energy

Solar mounts, electrical boxes

Equipment

Tool boxes, storage systems

Furniture

Office furniture, shelving

The Rapidaccu Difference

Excellence in every aspect of steel fabrication

Industry Experience

Proven track record in steel fabrication

Quality Certified

ISO 9001:2015 quality management

Quality Inspection

Every component thoroughly verified

Global Shipping

Worldwide delivery capabilities

Frequently Asked Questions

Find answers to common questions about steel sheet metal fabrication

What is the difference between cold rolled and hot rolled steel?

What thicknesses of steel sheet can you fabricate?

Do you offer corrosion protection for steel parts?

What tolerances can you achieve?

Can you handle both prototypes and production runs?

What file formats do you accept for designs?

Related Sheet Metal Materials

Explore alternative materials for your manufacturing needs

Copper Sheet Metal

Exceptional electrical and thermal conductivity makes copper ideal for electrical components, heat exchangers, and decorative applications. Natural antimicrobial properties perfect for healthcare environments.

Learn More About Copper →

Tool Steel Sheet Metal

Extreme hardness and wear resistance make tool steel perfect for demanding applications. Ideal for cutting tools, dies, punches, and components requiring superior durability and edge retention.

Learn More About Tool Steel →

Inconel Sheet Metal

Superior high-temperature strength and oxidation resistance for extreme environments. Perfect for aerospace, chemical processing, and applications requiring performance at elevated temperatures.

Learn More About Inconel →Request Your Custom Quote

Transform your steel fabrication project into reality with Rapidaccu. Our expert team delivers precision, quality, and reliability for every component.

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comManufacturing Expertise

15 Years in Custom Parts Manufacturing Excellence