- Home ›

- Sheet Metal Fabrication ›

- Tool Steel Sheet Metal Fabrication

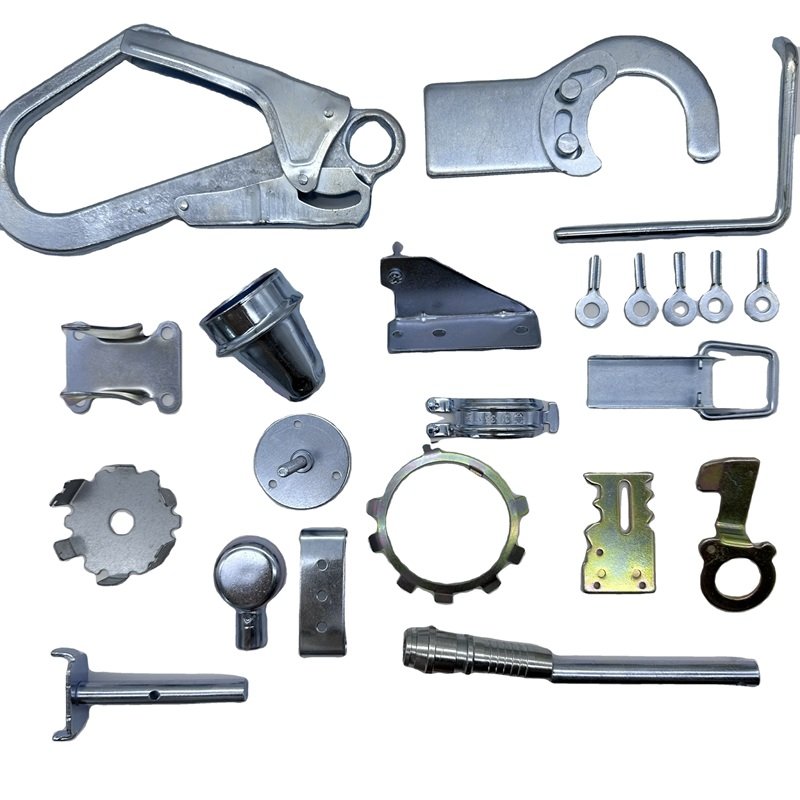

Tool Steel Sheet Metal Fabrication

Rapidaccu specializes in precision tool steel sheet metal fabrication with 15 years of advanced manufacturing experience. We deliver high-performance tool steel components engineered for extreme hardness, wear resistance, and durability in the most demanding applications.

What Makes Tool Steel Exceptional?

Tool steel delivers unmatched performance characteristics for precision tooling and high-wear applications

Extreme Hardness

Achieves hardness levels of 60-67 HRC through heat treatment, providing exceptional resistance to deformation and wear in demanding applications.

Wear Resistance

Superior abrasion and erosion resistance extends tool life significantly, reducing replacement costs and downtime in production environments.

High Temperature Stability

Maintains hardness and strength at elevated temperatures, ideal for hot working operations and high-speed cutting applications.

Dimensional Stability

Minimal distortion during heat treatment ensures precise tolerances and consistent part geometry for critical applications.

Impact Toughness

Excellent shock resistance prevents chipping and cracking under impact loading conditions typical in stamping and forming operations.

Formability

Annealed condition allows for complex bending and forming operations before hardening, enabling precise sheet metal fabrication with intricate shapes.

Tool Steel Grades & Applications

We work with a comprehensive range of tool steel grades optimized for specific performance requirements

D2 Tool Steel

Cold WorkComposition: 1.5% C, 12% Cr, 1% Mo, 1% V

Hardness: 58-62 HRC after heat treatment

High-carbon, high-chromium tool steel with excellent wear resistance and moderate toughness. Air-hardening grade minimizes distortion during heat treatment.

Ideal Applications:

- Stamping and blanking dies

- Punches and forming tools

- Shear blades and knives

- Thread rolling dies

A2 Tool Steel

Cold WorkComposition: 1% C, 5% Cr, 1% Mo

Hardness: 57-62 HRC after heat treatment

Air-hardening tool steel with excellent dimensional stability and good toughness. Balanced properties for versatile tooling applications.

Ideal Applications:

- Precision cutting tools

- Gauges and measuring instruments

- Dies for intricate work

- Punches requiring toughness

O1 Tool Steel

Oil HardeningComposition: 0.9% C, 1.2% Mn, 0.5% Cr

Hardness: 57-62 HRC after heat treatment

Oil-hardening tool steel offering excellent machinability and low distortion. Cost-effective solution for general-purpose tooling applications.

Ideal Applications:

- Cutting tools and knives

- Woodworking tools

- Taps and reamers

- Plastic mold components

H13 Tool Steel

Hot WorkComposition: 0.4% C, 5% Cr, 1.5% Mo, 1% V

Hardness: 42-52 HRC after heat treatment

Premium hot work tool steel with superior toughness and thermal fatigue resistance. Maintains hardness at elevated temperatures up to 1000°F.

Ideal Applications:

- Hot forging dies

- Extrusion tooling

- Die casting dies

- Hot shearing blades

Tool Steel Sheet Metal Fabrication Services

Precision Laser Cutting

Advanced fiber laser cutting of annealed tool steel sheets. Achieve complex patterns, intricate geometries, and tight tolerances with clean edges and minimal heat-affected zones.

Press Brake Bending

Precision press brake forming of annealed tool steel sheets. Create accurate bends, folds, and angles with repeatable precision for complex part geometries.

Punching & Stamping

High-precision CNC turret punching for holes, slots, and cutouts. Progressive die stamping for high-volume production with consistent quality and minimal waste.

TIG Welding

Specialized TIG welding for tool steel sheet metal assemblies. Creates strong, clean welds while maintaining material integrity and minimizing distortion in fabricated parts.

Surface Finishing

Comprehensive surface treatments including deburring, grinding, polishing, and protective coatings. Enhance appearance, prevent corrosion, and improve part functionality.

Industrial Applications

Stamping & Forming

Progressive dies, blanking dies, punches, forming tools for high-volume metal stamping operations.

Plastic Injection Molds

Mold cavities, cores, inserts, and wear plates for precision plastic injection molding applications.

Cutting Tools

Shear blades, slitting knives, cutting dies, paper knives requiring sharp edges and wear resistance.

Extrusion Dies

Hot extrusion dies, mandrels, and tooling for aluminum, copper, and plastic extrusion processes.

Forging Tools

Hot forging dies, upset tooling, header dies for high-temperature metal forming operations.

Precision Gauges

Measuring tools, inspection fixtures, master gauges requiring dimensional stability and accuracy.

Quality Assurance & Testing

Material Verification

Spectroscopic analysis confirms chemical composition. Mill certificates provided for full traceability.

Hardness Testing

Rockwell hardness testing on every component to verify proper heat treatment and hardness levels.

Dimensional Inspection

CMM and precision measuring equipment ensure all dimensions meet drawing specifications.

ISO Certification

ISO 9001:2015 certified facility with documented quality management systems and procedures.

Frequently Asked Questions

What is the difference between tool steel and regular steel?

Can you fabricate tool steel before heat treatment?

What hardness levels can you achieve?

What thicknesses of tool steel sheet can you fabricate?

Do you offer surface coating services?

What documentation do you provide?

Premium Sheet Metal Materials

Select from our extensive range of high-performance materials for your next project

Aluminum

Lightweight excellence for aerospace and automotive industries with superior corrosion resistance

Stainless Steel

Premium durability for medical, food processing, and marine applications

Steel

Cost-effective strength for structural and heavy-duty industrial applications

Copper

Superior electrical conductivity with natural antimicrobial properties

Bronze

Exceptional wear resistance for marine and bearing applications

Titanium

Aerospace-grade strength with biocompatibility for medical implants

Inconel

Ultimate high-temperature superalloy for extreme environments

Cast Iron

Superior damping and wear resistance for heavy machinery

Brass

Decorative elegance with natural antimicrobial properties

Start Your Tool Steel Project

Partner with Rapidaccu for precision tool steel fabrication. Our specialized expertise ensures your components meet the most demanding specifications for hardness, wear resistance, and dimensional accuracy.

Facility Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comExperience

15 Years in Precision Tool Steel Fabrication