Professional Die Stamping Services

Rapidaccu is a leading die stamping manufacturer delivering precision metal components through expertly designed custom dies. With advanced tooling capabilities and 15 years of manufacturing excellence, we transform your concepts into high-quality stamped parts for any industry.

What is Die Stamping?

Die stamping is a versatile metalworking process that uses custom-designed dies to cut, bend, and shape sheet metal into precise components. Through the application of high tonnage pressure, the die transforms flat metal into complex parts with exceptional accuracy, repeatability, and cost-efficiency for volume production.

Blanking & Piercing

Precision cutting operations creating parts and features with clean edges and tight tolerances.

Bending & Forming

Creating complex angles, curves, and three-dimensional shapes with precision and consistency.

Embossing & Coining

Adding raised or recessed features for aesthetics, identification, or functional purposes.

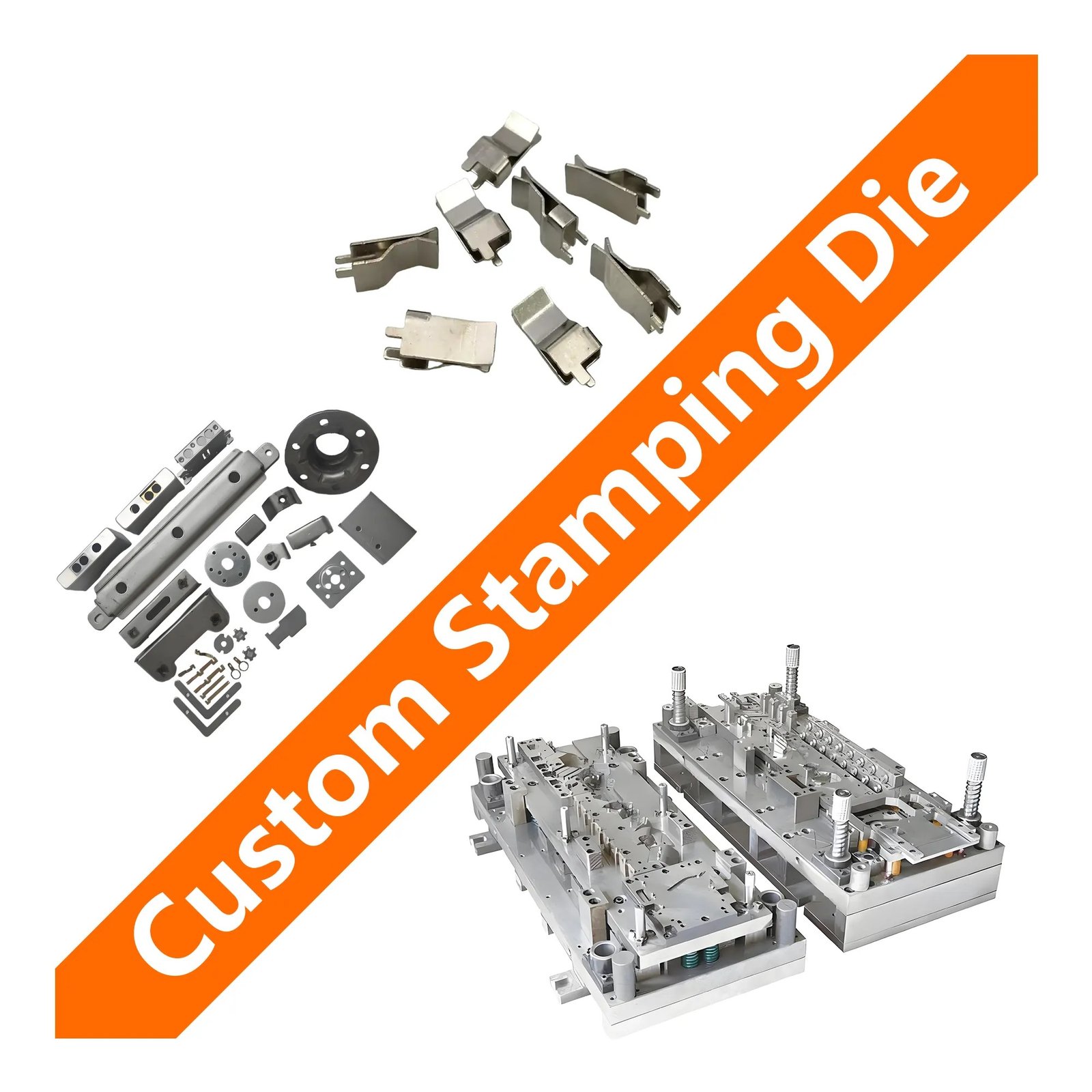

Comprehensive Die Stamping Solutions

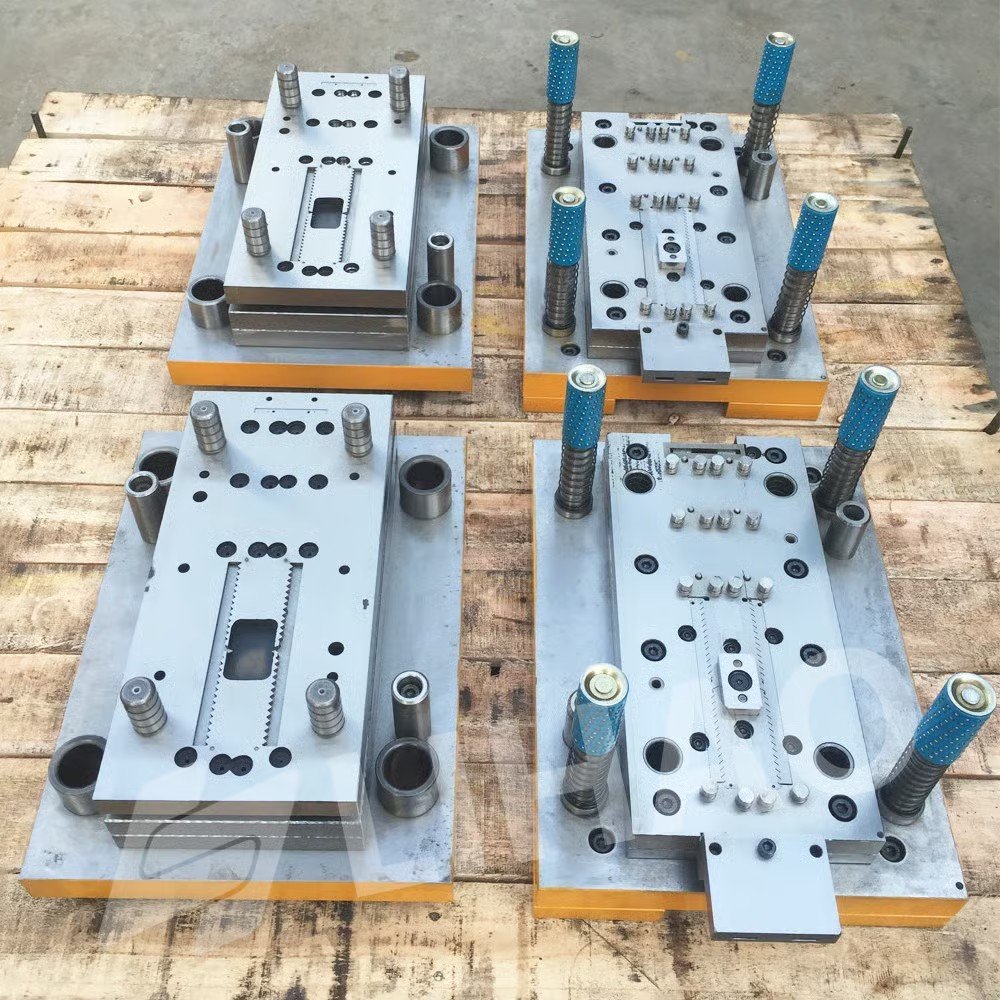

Die Types & Technologies

Single-Stage Dies

One operation per press stroke for simple parts and prototyping

Compound Dies

Multiple operations in one stroke for faster production cycles

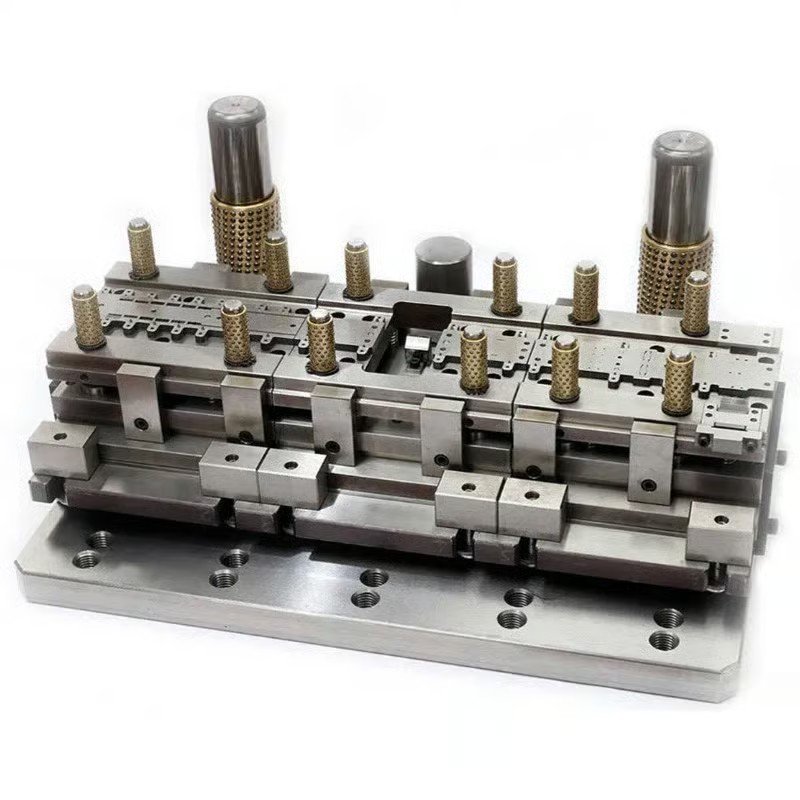

Progressive Dies

Sequential multi-station operations for complex geometries

Transfer Dies

Large part handling with automated transfer between stations

Material Capabilities

Technical Specs

Quality Guarantee

- ISO Certified Manufacturing

- 100% Inspection Available

- CMM Measurement

- Material Certification

Die Stamping Products Showcase

Industry Applications

Automotive

Brackets, panels, clips, fasteners, structural components, trim parts

Electronics

Connectors, shields, contacts, enclosures, heat sinks, lead frames

Appliances

Control panels, frames, doors, hinges, decorative and functional parts

Industrial

Machine guards, housings, mounting plates, conveyor components

Construction

Connectors, brackets, HVAC parts, architectural hardware, fittings

Hardware

Locks, keys, hinges, latches, fasteners, decorative hardware

Medical

Surgical instruments, device housings, equipment parts, trays

Aerospace

Brackets, clips, panels, connectors, precision structural parts

Why Choose Rapidaccu for Die Stamping?

As a premier die stamping manufacturer with 15 years of experience, Rapidaccu combines expert die design, advanced manufacturing technology, and rigorous quality control to deliver exceptional stamped components that meet your exact specifications.

Years Experience

Extensive expertise in custom die design and high-precision stamping operations

Custom Die Design

In-house toolmakers creating optimized dies for your specific requirements

Quality Assurance

ISO-certified manufacturing with comprehensive quality inspection systems

Dedicated Support

Collaborative approach from design through production and delivery

Die Stamping FAQs

What is the difference between die types?

What volumes are economical for die stamping?

How long does die development take?

What materials can be die stamped?

Do you provide die maintenance?

How do I request a die stamping quote?

Request Your Die Stamping Quote

Let’s bring your precision stamping project to life

Contact Details

Factory Address

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Business Hours

Monday – Friday: 8:00 AM – 6:00 PM

Saturday: 9:00 AM – 5:00 PM

(China Standard Time)